Liquid Additive Manufacturing Material Launched

This liquid silicone rubber can be 3D printed and has a 50 Shore A hardness

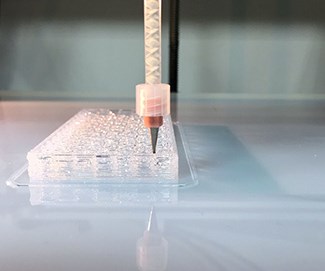

(Images: Dow)

Odds are, if you’re going to prototype something, ideally what you’ve made as a one- (or so) off is something that might scale to production.

And it would be particularly good were the material used to produce said model be capable of being ported over to production.

And colors, too

Dow has launched a new two-part platinum-catalyzed, thermoset liquid silicone rubber (LSR), SILASTIC 3D 3335, that can be used in liquid additive manufacturing (LAM) processes, such as that performed by the German RepRap L320 3D printer.

The LSR material is transparent. Which is useful in some applications.

But Dow and German RepRap have been working with an Austrian company, Nexus Elastomer Systems, on a dosing system that allows the use of companion color packs from Mesgo Iride Colors, an Italian company.

(It is worth noting that this Euro-centric tech is being shown at the K 2019 Trade Fair in Düsseldorf.)

And about that transition. . .

According to Dow, “Properties of 3D-printed parts are comparable to injection-molded components” and “Transfers easily to injection-molding processes for high-volume manufacturing.”

Which is the ideal end state for a prototype part.

RELATED CONTENT

-

Multiple Choices for Light, High-Performance Chassis

How carbon fiber is utilized is as different as the vehicles on which it is used. From full carbon tubs to partial panels to welded steel tube sandwich structures, the only limitation is imagination.

-

Things to Know About Cam Grinding

By James Gaffney, Product Engineer, Precision Grinding and Patrick D. Redington, Manager, Precision Grinding Business Unit, Norton Company (Worcester, MA)

-

Choosing the Right Fasteners for Automotive

PennEngineering makes hundreds of different fasteners for the automotive industry with standard and custom products as well as automated assembly solutions. Discover how they’re used and how to select the right one. (Sponsored Content)

.jpg;width=70;height=70;mode=crop)