NVIDIA Offers “Orin”; Fighting Cyberattacks; Under the Radar Weight Savings

NVIDIA Offers “Orin”; Fighting Cyberattacks; Under the Radar Weight Savings

#robotics #hybrid #electronics

Autonomously Focused NVIDIA Offers “Orin”

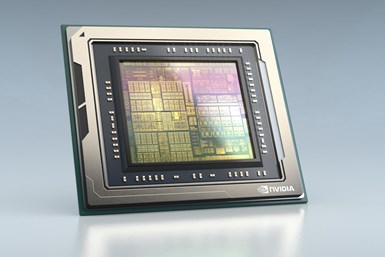

Try as they might, it’s hard for technology marketing executives to make chipsets sound sexy. The new NVIDIA DRIVE AGX (www.nvidia.com) carries a name that has a certain sports car ring to it. But it’s what the tech proposes to do–anything from serving as a platform for autonomous vehicles to robots–that adds some potential excitement to the innovation.

NVIDIA’s platform is made of made up of 17 billion transistors, as well as four years of R&D, and is powered by a new system-on-a-chip called Orin.

The platform is made of 17 billion transistors, as well as four years of R&D, and is powered by a new system-on-a-chip called Orin. Orin’s mission is managing all those applications and the deep neural networks that need to run in the background for autonomous vehicles and robots. Orin also integrates NVIDIA’s next-generation graphics architecture. Taken together, the system delivers 200 trillion operations per second—nearly seven times the performance of NVIDIA’s previous-generation setup.

It was all created to support platforms that scale from a Level 2 to full self-driving Level 5 vehicles. And NVIDIA is rolling it out to attract OEMs looking to build supporting software products at scale that requires plenty of processing power to perform. The family will include a range of configurations based on a single architecture, targeting automakers’ 2022 production timetables.

“Creating a safe autonomous vehicle is perhaps society’s greatest computing challenge,” said Jensen Huang, NVIDIA founder and CEO. “The amount of investment required to deliver autonomous vehicles has grown exponentially, and the complexity of the task requires a scalable, programmable, software-defined AI platform like Orin.”

Fighting Cyberattacks with (Test) Cyberattacks

Of all the high-tech things that could go wrong with a semi-autonomous vehicle, from software glitches to network failures, the idea of a car being hacked is fairly easy for most people to understand. It’s also one of the key reasons the public remains, at best, circumspect about the prospects of driverless vehicles dominating the highways and city streets.

Denso (denso.com) and NTT Communications Corporation (ntt.com) say they will be validating their jointly developed Vehicle Security Operation Center (V-SOC) technology, designed for monitoring and analyzing vehicle’s security status. The overarching goal: Prevent cyberattacks on connected cars, which continue to grow in both capabilities and therefore in cyber vulnerabilities.

They need security technology that can swiftly detect and analyze cyberattacks and then seamlessly provide the appropriate support according to the situation. Since 2017, DENSO and NTT Com have been developing V-SOC technology to quickly detect and analyze cyberattacks.

The next step is hitting autonomous vehicle systems with a battery of different types of cyberattacks on test vehicles to find out how effectively their solution fends them off. The idea is to continuously improve the software with the onslaught of cyberattacks.

Denso will provide information security, vehicle communication, and data analysis technologies used in in-vehicle systems. For its part, NTT Com will use its technology to evaluate networks, cloud computing and security services.

Batteries Unbound

The original 2011 Chevrolet Volt battery weighed in at 435 pounds. The Tesla Model 3’s power pack tips the scales at 1,054 pounds. While those are two very different electric drive vehicles (with very different battery pack demands), weight doggedly remains one of the biggest obstacles to the spread of EVs.

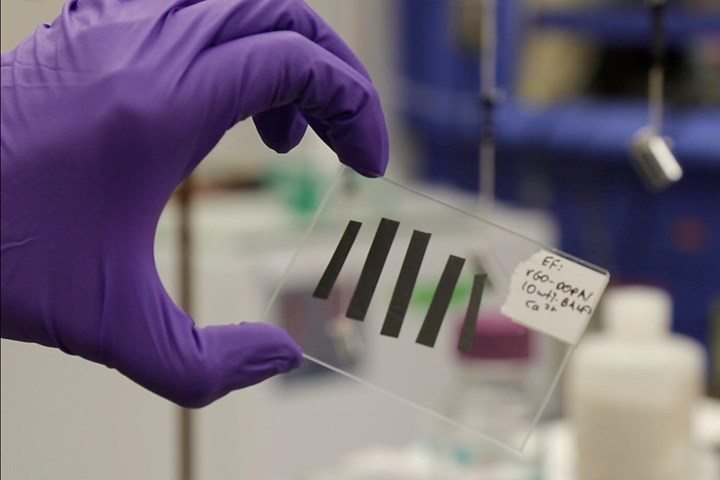

Texas A&M University College of Engineering scientists show off electrodes so strong, they say they could double as batteries in places like body panels for electric vehicles.

While increasing energy density of batteries and supercapacitors has been one of the deeper research veins, a team from the Texas A&M University College of Engineering (tamu.edu) is taking a more holistic view. The researchers say significant weight loss can be found by storing energy within the structural body panels. That would require making mechanically strong batteries and supercapacitors with similar properties to that of body panels. It’s a rather big challenge considering batteries and supercapacitor electrodes are often formed with brittle materials, without much in the way of mechanical strength.

Led by chemical engineering professor Jodie Lutkenhaus, the research led to an entirely new family of structural electrodes. In an article published in the journal Matter, they describe the process of creating new supercapacitor electrodes based on dopamine functionalized graphene and Kevlar nanofibers, structures the scientists claim have drastically improved the mechanical properties.

Dopamine, which is also a neurotransmitter, is a highly adhesive molecule that mimics the proteins that allow mussels to stick to virtually any surface. The use of dopamine and calcium ions also leads to a significant improvement in mechanical, scientists note.

Under the Radar Weight Savings

If the hardware is heavy, perhaps the right software can do a chunk of the heavy lifting. Or so goes the thinking from Oculii (oculii.com) and Infineon (infineon.com), which are collaborating on radar software designed to overcome the weight challenges presented by the demands of radar. The two firms believe their tech will scale up the performance of single-chip solutions geared toward anything from Level 1 ADAS, all the way to multi-chip systems required for Level 4 Autonomous Driving.

To gain higher angular resolution, radar systems need more physical antennas, resulting in higher power needs and more weight. Oculii's Virtual Aperture Imaging radar software increases the angular resolution of an array, without the need for more physical transceiver technology, while achieving up to 10X+ increase in angular resolution. All of that could add up to worthwhile weight savings, the companies report.

Infineon will pair its chipset containing AURIX microcontroller units, integrated circuits and power supply hardware platform with Oculii’s Virtual Aperture Imaging software for OEMs and Tier-1 suppliers later this year.

“Our team has demonstrated that our software architecture can improve angular resolution and field of view by an order of magnitude,” said Oculii CEO Steven Hong. “We are looking forward to collaborating with Infineon to bring this technology to the broader automotive market.”

RELATED CONTENT

-

Robots and Auto

Industrial robots are part and parcel of the auto industry and will continue to be, regardless of what politicians think.

-

Cobots: 14 Things You Need to Know

What jobs do cobots do well? How is a cobot programmed? What’s the ROI? We asked these questions and more to four of the leading suppliers of cobots.

-

On Developments at Lincoln, Magna, Fiskar, Volvo and More

Lincoln’s plans for electric; Magna and Fisker working together; Polestar in South Carolina; the Volvo XC60 driven; VW gets deep into 3D; Porsche exec on electric; BMW and hydrogen; Staubli cell for tire sensors; and Bridgestone invests in autonomous trucking company.