Hyundai’s Remarkable Hybrid

Hyundai enters the American market with a new parallel hybrid system that uses lithium-polymer batteries and the same six-speed automatic found in non-hybrid versions of the 2011 Sonata.

#hybrid

Although other vehicle manufacturers have offered and continue to offer hybrid systems, there has been none that is like the Direct Hybrid Blue Drive technology that Hyundai is introducing in the 2011 Sonata Hybrid. It is on the one hand more technically advanced than others that are available on the market, and on the other hand somewhat simpler, or more akin to a conventional powertrain than those that are offered by other manufacturers.

Hyundai is utilizing a lithium-polymer battery pack rather than nickel-metal hydride batteries or conventional lithium-ion batteries*. This is a next-generation lithium-ion battery technology that utilizes manganese spinel chemistry. What you need to know about that is simply that manganese spinel chemistry is long-lived—capable of tens of thousands of charge cycles, or, more to the point, to meet what Hyundai describes as “10-year-and-beyond longevity.” One reason why is that it exhibits better thermal stability than the electrodes in less-advanced lithium-ion chemistries. What happens in battery packs based on that chemistry is that as they are charged and discharged, there is an expansion and contraction associated with the heating and cooling cycles involved. This leads to cracks in the electrodes, which leads to a lessened ability to hold a charge.

Speaking of the charge: the battery is said to hold its charge 25% longer than nickel-metal hydride batteries. Hyundai developed the batteries with LG Chem. Because it has power density, the Sonata Hybrid’s 1.4-kWh battery pack is comparatively light, weighing 95.9 lb. Hyundai compares that mass to the mass of the nickel-metal hydride battery pack in the Toyota Camry Hybrid, which is 123.9 lb., so there is a 28 lb. difference. Another benefit of the type of cell being used for the Sonata Hybrid is that it has a flat, rectangular shape rather than the cylindrical shape that’s often used for hybrid batteries, so cells can be combined into battery packs that are more compact, as much as 20% smaller, than systems based on cylindrical cells.

Another reason space is saved: there is no need for a liquid cooling system. Air from the interior of the car is drawn into the battery area and exhausted out the back of the vehicle.

On the “somewhat simpler” vector, there is what is really quite a clever bit of engineering. The Direct Hybrid Blue Drive System uses what is essentially a conventional step-gear automatic transmission. The six-gear transmission in the standard 2011 Sonata is used in the Sonata Hybrid with the primary functional difference being that in the hybrid application there is an external electrically driven oil pump. It’s necessary because when the car goes into idle stop (i.e., when the car comes to a stop and if there is a low electrical draw on the system, the engine is shut off), there needs to be a means to have sufficient hydraulic fluid pressure to maintain clutch pressure. There are other modifications, like the addition of a new case and torsion damper, but fundamentally, the architecture of the system is such that off-the-shelf transmissions developed for traditional internal combustion engines can be deployed for future hybrid systems without having to incur major engineering costs. In this application, it is essentially the same transmission and the same 2.4-liter inline four cylinder engine for the standard powertrain and the hybrid.

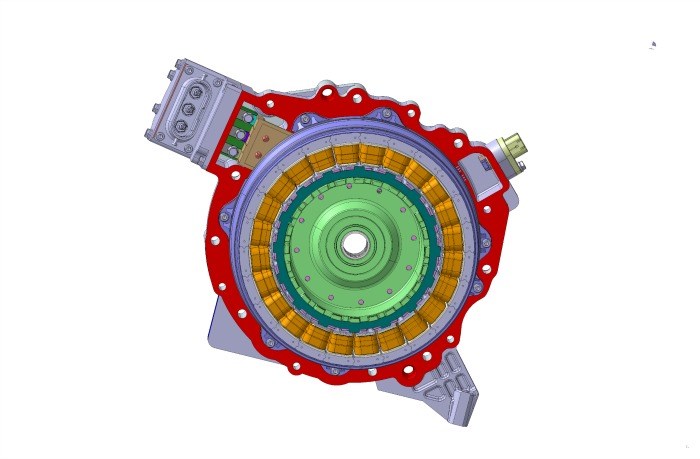

The hybrid setup deploys a 30-kW permanent magnet syn-chronous electric traction motor that provides 151 lb-ft of torque. It is hard-coupled to the input of the transmission where the torque converter would ordinarily be found. There is a multiple-disc clutch pack in the traction motor that is used to decouple the motor from the internal combustion engine when the vehicle is in electric drive mode (it is said to be able to drive in electric mode at up to 62 miles per hour, and this capability was essentially verified during a test drive on the 805 north of San Diego) or when the car is at idle-stop.

As the motor sits where the torque converter would be, there’s no torque converter to smooth out the shifts. While one could have been deployed, Hyundai engineers decided not to for a variety of reasons (weight, cost, complexity), not the least of which is that the Sonata has a transverse-mounted powertrain setup, so there is simply no room.

Another important element of the system is the Hybrid-Starter-Generator (HSG). This is not like the belt alternator starter system that General Motors introduced in the 2007 Saturn Vue Green Line, which not only had the function of starting the engine after it had been shut off for idle stop, but which could also provide power assist during acceleration. The HSG’s function is to start the engine from an idle stop and to charge the hybrid battery if required.

While this is Hyundai’s first full parallel hybrid, it is not its first commercially available hybrid system. Its first was a mild-hybrid Elantra available in the Korean market in mid-2009. Given the modular architecture of the Direct Hybrid Blue Drive, it is fairly likely that there will be more hybrids to come from Hyundai, sooner rather than later.

*It should be noted that Mercedes offers lithium-ion batteries in its S400 sedan and ML450 SUV Hybrids, but the Hyundai battery uses a different chemistry. So the comparison may not be apples and oranges but perhaps oranges and tangerines.Hyundai is utilizing a lithium-polymer battery pack rather than nickel-metal hydride batteries or conventional lithium-ion batteries*. This is a next-generation lithium-ion battery technology that utilizes manganese spinel chemistry. What you need to know about that is simply that manganese spinel chemistry is long-lived—capable of tens of thousands of charge cycles, or, more to the point, to meet what Hyundai describes as “10-year-and-beyond longevity.” One reason why is that it exhibits better thermal stability than the electrodes in less-advanced lithium-ion chemistries. What happens in battery packs based on that chemistry is that as they are charged and discharged, there is an expansion and contraction associated with the heating and cooling cycles involved. This leads to cracks in the electrodes, which leads to a lessened ability to hold a charge.

Speaking of the charge: the battery is said to hold its charge 25% longer than nickel-metal hydride batteries. Hyundai developed the batteries with LG Chem. Because it has power density, the Sonata Hybrid’s 1.4-kWh battery pack is comparatively light, weighing 95.9 lb. Hyundai compares that mass to the mass of the nickel-metal hydride battery pack in the Toyota Camry Hybrid, which is 123.9 lb., so there is a 28 lb. difference. Another benefit of the type of cell being used for the Sonata Hybrid is that it has a flat, rectangular shape rather than the cylindrical shape that’s often used for hybrid batteries, so cells can be combined into battery packs that are more compact, as much as 20% smaller, than systems based on cylindrical cells.

Another reason space is saved: there is no need for a liquid cooling system. Air from the interior of the car is drawn into the battery area and exhausted out the back of the vehicle.

On the “somewhat simpler” vector, there is what is really quite a clever bit of engineering. The Direct Hybrid Blue Drive System uses what is essentially a conventional step-gear automatic transmission. The six-gear transmission in the standard 2011 Sonata is used in the Sonata Hybrid with the primary functional difference being that in the hybrid application there is an external electrically driven oil pump. It’s necessary because when the car goes into idle stop (i.e., when the car comes to a stop and if there is a low electrical draw on the system, the engine is shut off), there needs to be a means to have sufficient hydraulic fluid pressure to maintain clutch pressure. There are other modifications, like the addition of a new case and torsion damper, but fundamentally, the architecture of the system is such that off-the-shelf transmissions developed for traditional internal combustion engines can be deployed for future hybrid systems without having to incur major engineering costs. In this application, it is essentially the same transmission and the same 2.4-liter inline four cylinder engine for the standard powertrain and the hybrid.

The hybrid setup deploys a 30-kW permanent magnet syn-chronous electric traction motor that provides 151 lb-ft of torque. It is hard-coupled to the input of the transmission where the torque converter would ordinarily be found. There is a multiple-disc clutch pack in the traction motor that is used to decouple the motor from the internal combustion engine when the vehicle is in electric drive mode (it is said to be able to drive in electric mode at up to 62 miles per hour, and this capability was essentially verified during a test drive on the 805 north of San Diego) or when the car is at idle-stop.

As the motor sits where the torque converter would be, there’s no torque converter to smooth out the shifts. While one could have been deployed, Hyundai engineers decided not to for a variety of reasons (weight, cost, complexity), not the least of which is that the Sonata has a transverse-mounted powertrain setup, so there is simply no room.

Another important element of the system is the Hybrid-Starter-Generator (HSG). This is not like the belt alternator starter system that General Motors introduced in the 2007 Saturn Vue Green Line, which not only had the function of starting the engine after it had been shut off for idle stop, but which could also provide power assist during acceleration. The HSG’s function is to start the engine from an idle stop and to charge the hybrid battery if required.

While this is Hyundai’s first full parallel hybrid, it is not its first commercially available hybrid system. Its first was a mild-hybrid Elantra available in the Korean market in mid-2009. Given the modular architecture of the Direct Hybrid Blue Drive, it is fairly likely that there will be more hybrids to come from Hyundai, sooner rather than later.

*It should be noted that Mercedes offers lithium-ion batteries in its S400 sedan and ML450 SUV Hybrids, but the Hyundai battery uses a different chemistry. So the comparison may not be apples and oranges but perhaps oranges and tangerines.

RELATED CONTENT

-

Visteon's common soft touch

Visteon has developed a process that aims to bridge the gap between luxury soft-touch instrument panels and the rock-hard plastics of the lower orders. It uses fewer parts, needs no custom equipment and is fully recyclable.

-

On Charging, Sustainable Tires, the Lincoln Nautilus and more

Charging at home, driving on plastic, cameras for exterior, Fisker and Foxconn, and the Lincoln Nautilus reviewed

-

Plastics: The Return of Body Panels?

A problem with plastics and steel structures is a difference in the coefficient of expansion. Some material modifications may ameliorate that problem.

.jpg;width=70;height=70;mode=crop)