on lasers for batteries, award-winning designs, Bosch & SiC, Toyota & H2

Precise heating for electrode manufacture. . .EV travel trailer. . .products with great designs. . .Hot Wheels custom competition. . .Honda and its motorcycles. . .Bosch buys a chip factory. . .Toyota’s fuel cell kit. . .Hyundai and the Moon. . .AI in your car. . .Mercedes and a scooter subscription. . . .

#electronics

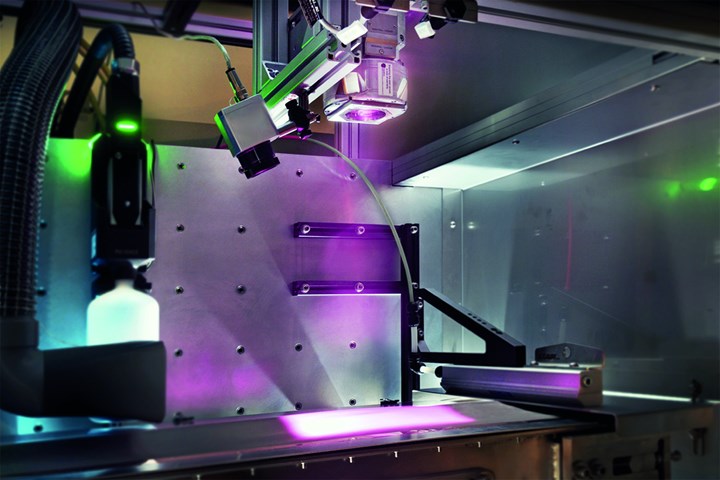

Energy Efficient Electrode Processing with Lasers

Using a laser to cure graphite-based electrodes is more efficient than the standard procedure of using ovens. (Image: Fraunhofer ILT)

One of the things electric vehicles can bring to transportation is energy efficiency.

U.S. Department of Energy:

“EVs convert over 77% of the electrical energy from the grid to power at the wheels. Conventional gasoline vehicles only convert about 12%–30% of the energy stored in gasoline to power at the wheels.”

But the manufacture of lithium-ion batteries isn’t necessarily energy efficient.

Take the production of graphite-based electrodes.

There is a copper foil. It is coated with a graphite paste. Then that’s cured in a gas-powered continuous furnace that’s at from 160 to 180°C. The foil is fed through the oven on a conveyor belt.

The ovens are sizable: between 60 and 100 meters long.

It takes a lot of energy to have that space heated.

There is a better way.

Lasers.

Fraunhofer ILT researchers in Germany developed a drying system that uses a diode laser (>20 kW). Special optics were developed by a diode laser specialist company Laserline GmbH. The optics illuminate electrode over a wide area, with beam widths of some 1.5 meters.

Explains Samuel Fink, group leader for Thin Film Processing at Fraunhofer ILT:

“In contrast to the hot-air drying process, our diode laser projects a high-intensity bean onto the copper foil, which is coated with graphite paste.

“The jet-black graphite absorbs the energy. The resulting interaction causes the graphite particles to heat up and the liquid to evaporate.”

And here’s the efficiency:

“Drying with the diode laser,” Fink says, “will reduce the energy required by up to 50% and the space needed for a drying system on an industrial scale by at least 60%.”

///

An EV Designed to be Towed

A stylish travel trailer that happens to also be an EV. (Image: Lightship)

“Inefficient, unreliable product designs and a power experience that relies on smelly, noisy, gas or propane generators fundamentally hinder the amazing experience of traveling in the outdoors.”--Ben Parker, Lightship Co-Founder and CEO

Parker, it is worth noting, spent five years at Tesla, including participating in the ramp of the Model 3 and working on the company’s next-gen battery design. He left Tesla at the start of the pandemic and took a 6,000-mile RV road trip in the U.S. southwest, which:

- Gave him a first-hand understanding of the inefficiencies and odors

- Led to him co-founding Lightship (with another Telsa alum, Toby Kraus, who had also spent time at Proterra, the company specializing in electrifying things like buses and delivery vehicles)

Lightship has developed a battery-powered trailer, described by Tony Fadell, who invented the iPod and was the founder of Nest (and whose Build Collective has invested in Lightship), as being “not an ancient RV that’s been ‘electrified.’”

The Structure

Nor is this some small trailer: the Lightship 1 trailer is 27 feet long and 8 feet, 6 inches wide.

The vehicle, which will be manufactured in Colorado, is a mixed-materials structure consisting of metals, plastics and composites. The company has focused on sourcing recycled or sustainably derived materials.

Unlike traditional travel trailers, the Lightship 1 has an electric powertrain (they’re keeping stats to themselves for now) that’s powered by a standard 40-kWh or an optional 80-kWh battery.

The roof of the trailer has a solar array on its surface that can provide up to 3 kW.

Smooth Moves

A focus was made on making the Lightship 1 aerodynamic.

According to a company spokesperson, “We find that the L1 actually improves the Cd [coefficient of drag] of many combustion-engine trucks versus their unladen Cd.”

They say that the trailer is some three times as aerodynamic as a traditional travel trailer.

The package is setup with the travel objective of not reducing the range of the vehicle towing the trailer.

And when at the camp site, not being smelly or noisy.

///

Good Industrial Form

The Mercury Marine Avator 7.5e electric outboard motor features an award-winning design. (Image: Mercury Marine)

The Mercury Marine Avator 7.5e electric outboard motor certainly doesn’t fit within the category “Automotive.” But as we are keen on design the motor came to our attention because it received a 2023 iF Design award, one of the most important acknowledgments of design excellence in the world.

(When the association behind it was founded in Hannover in 1953 it was initially known as “Die gute Industrieform e.V.,” or “Good Industrial Form.” It later was simplified to “Industrie Forum,” or “iF.)

Features cited about the outboard—in addition to it being clean and quiet—includes that the 1-kWh lithium-ion battery is fitted under the flip-up top cowl. The battery can be quickly released with a trigger mechanism and there is a handle designed into the battery so it can be readily carried.

Presumably the designers spent some time at docks and on the water.

And the Functionality

The Avator features what Mercury Marine says is an “industry-first transverse flux motor.” The outboard produces 750 W of power at the prop shaft. The speed and performance it provides is described as being analogous to a Mercury 3.5-hp FourStroke combustion engine—and it is 75% quieter at full throttle compared to the gas-powered engine.

Speaking of full throttle, the Avator 7.5e tested on a 13-foot Veer V13 boat, is able to operate for 60 minutes or five miles when going all out on one battery charge.

For those being less aggressive, it can run at a constant 25% throttle for up to 19 hours or 30 miles (though your conditions may vary).

Reasons Why This Can Be Here

However, there are two legit reasons why this is in “on Automotive.”

- The motor obtained the prize in the iF Design “Automobiles/Vehicles” category

- The Avator 7.5e was designed by Designworks. . .a BMW company

(Some auto enthusiasts will say there are three reasons: Mercury Marine built the 375-hp 5.7-liter small-block V8, the LT-5, for the 1990 ZR-1 Corvette. For model year 1993 changes to the cam timing and engine porting brought the output to 405 hp. Production of the engine at the Mercury MerCruiser plant in Stillwater, Oklahoma, plant ended in 1994.)

///

Creative Caliper

And this Akebono brake caliper won a design award, as well. (Image: Akebono)

And while on the subject of design awards. . .

Not only did the Akebono Brake NR22 disc brake brake caliper for endurance racing win a Good Design Award last fall from the Japan Institute of Design Promotion (this design award was established in 1957: seems like design awards have some history), it also received an iF Design award like the Avator.

While calipers nowadays are generally painted some color (e.g., red) for purposes of attention, the mirror-finish surface on the NR22 is functional: it helps protect the braking system from radiant heat, thereby providing good braking characteristics during long runs.

And while generally calipers are more or less a Euclidean quadrilateral from side view, the NR22 is clearly more organic. Akebono designers and engineers applied shape optimization through structural analysis to come up with the design. It helps reduce mass by 7% compared with previous designs the company produced.

What’s more, the ribs not only provide strength to the structure, but they are hydraulic flow paths, as well.

An excerpt from a comment by the Good Design Award judging committee:

“The NR22 has pursued the utmost in functional performance under the demanding conditions of automobile endurance races, and in doing so has realized a beautiful form that is refined in addition to being well-organized and modern in appearance.”

Yes.

///

Real Cars Compete to Become Toys

The vehicle in that banner is the 2021 Hot Wheels Legends winner, a 1969 Volvo P1800. First a real custom car. Then a 1:64-scale car. (Image: Hot Wheels)

One more—more or less—about design. . .

The Hot Wheels Legends Tour will start on May 13 in Miami with a total of nine stops in the U.S. (all at Walmarts except for the final physical event, at Hot Wheels HQ in El Segundo, California), as well as events in 18 other countries.

While this may seem to be the stuff of a shrug except for toy enthusiasts, the event actually involves full-size custom cars.

Ted Wu, vice president and Global Head of Design for Vehicles, Mattel:

“More than 10,000 incredible cars were entered in last year’s Hot Wheels Legends Tour and this year we’re expecting even more as the Tour continues to grow. Not only are there more countries participating, but we expect each city to bring even more custom builds this year, making 2023 the most competitive Legends Tour yet.”

And Wu means full-size, actual cars.

Winner of the competition gets her or his car turned into a 1:64-scale vehicle. A Hot Wheels model.

Hmm. . .

Oddly, one of the main sponsors of the tour is Mobil 1.

Isn’t one of the characteristics of Hot Wheels is that they’re powered by gravity and consequently don’t need synthetic motor oils?

(The full-size, operative custom cars on the Tour, however. . . Clearly, the people at Mattel are quite clever.)

///

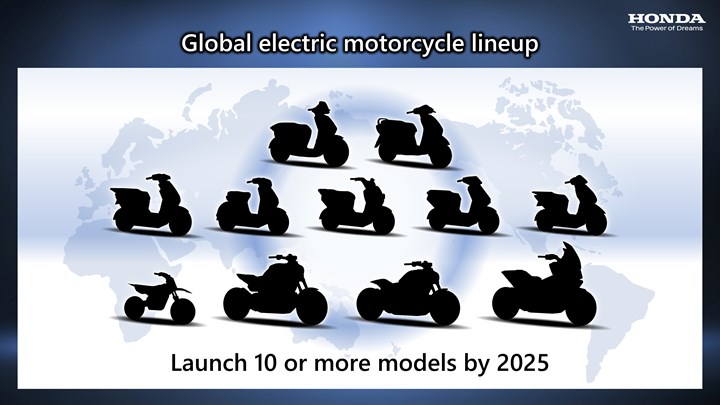

Two Wheelers Still Matter to Honda

Electric motorcycles—and motorcycles in general—are important to Honda. (Image: Honda)

Honda Motor Co., Ltd., held a business briefing yesterday regarding its 2023 business and beyond, covering topics including its effort in mobility, environment, electrification, batteries, software, and business structure.

One of the things that is evident is that while people might primarily think of “Honda” in the context of Civics or power generators, its motorcycle business—the product that launched the company—still plays a major role in for Honda.

As in:

“Moreover, due partly to the contribution of motorcycle business, which has established a strong earnings structure, Honda has been able to secure a sufficient level of free cash flow despite the tough business environment.”

And:

“Honda plans to introduce 10 or more electric motorcycle models globally by 2025 and aims to increase annual sales of electric models to 3.5 million units, equivalent to approximately 15% of total unit sales, as of 2030.”

Contrast that with this about vehicles with four wheels, not two:

“Honda is planning to produce more than 2 million EVs annually by 2030.”

Yes, 75% more electric motorcycles than electric cars, trucks and SUVs.

Two wheels have a bright future.

///

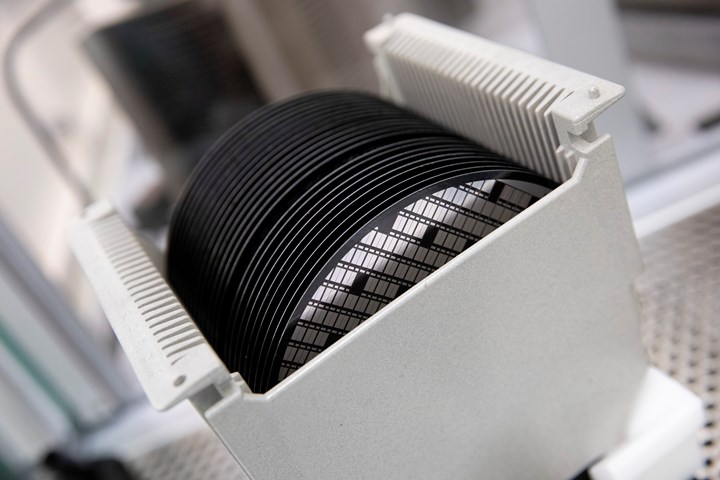

Bosch Building SiC Chip Capacity in California

Bosch silicon carbide semiconductor production will significantly ramp with the addition of a facility in California. (Image: Bosch)

The latest example of how the automotive supply chain is changing was announced yesterday:

- Bosch intends to acquire the assets of TSI Semiconductors of Roseville, California, then invest >$1.5-billion at the site to retool the operations to produce silicon carbide (SiC) chips on 200-mm wafers.

SiC chips are important elements in electric vehicles:

Compared with traditional silicon-based chips, they are more energy efficient in a vehicle’s power electronics, such that there can be a 6% increase in range for a given charge.

“With the acquisition of TSI Semiconductors, we are establishing manufacturing capacity for SiC chips in an important sales market while also increasing our semiconductor manufacturing, globally,” says Dr. Stefan Hartung, chair of the Bosch board of management.

Bosch operates wafer fabs in both Reutilingen and Dresden, Germany.

Chip making is nothing new for the company: it has been producing semiconductor in Reutlingen since 1970.

Strong Future

At this point, Bosch says the full investment in Roseville is predicated on funding from the federal CHIPS and Science Act and economic opportunities from the state of California.

Given that (1) Bosch expects that an average of 25 of its chips will be integrated into every new vehicle by 2025 and (2) the market for SiC chips is growing an average 30% per year, the company is committed to investment in the SiC space.

How important are semiconductors to Bosch?

Last summer, for example, it announced it is investing an additional 3 billion euros in its European semiconductor business, having already spent more than 2.5 billion euros on 200-mm tech.

///

Big Rigs and Emissions Issues (Especially in California)

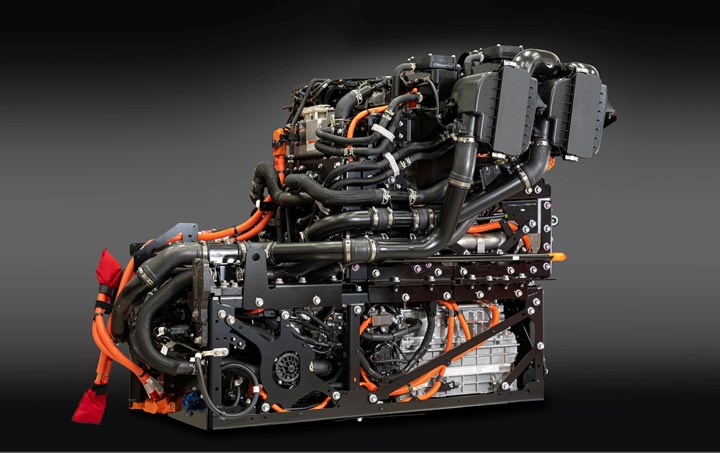

Toyota has developed a fuel cell kit for Class 8 trucks. (Image: Toyota)

Toyota announced earlier this week that it received a Zero Emission Powertrain (ZEP) Executive Order from the California Air Resources Board (CARB) for its heavy-duty fuel cell electric powertrain.

Meaning that the powertrain kit package—including hydrogen fuel storage tanks, fuel cell stacks, electric motors, batteries, and transmission—meets the emissions requirements for Class 8 trucks in the Golden State.

Going into Gliders

While the Toyota package isn’t simply something that an OEM or fleet owner can simply drop into an existing cab (i.e., pull the diesel and the transmission and put the Toyota kit in place—presto!), it goes a long way to simplifying the transition to a zero-emissions requirements.

According to a Toyota engineer, “The kit is designed for seamless integration to OEM-engineered gliders.”

Let’s face it: Truck manufacturers know how to build, well, Class 8 trucks. Fuel cells are far technologically trickier. Thus, the Toyota kit.

Chris Rovik, executive program manager, advanced mobility, Toyota Motor North America, said, “We believe hydrogen will play a significant role in the emissions reduction of heavy-duty transport while not sacrificing the distance, power, or fueling times needed to keep these fleet and individual operators running.”

Truckers’ California Concern

Spend a few minutes on the American Trucking Associations’ website and you’ll see that the organization—which represents “more than 34,000 motor carriers, moving & storage companies, and trucking suppliers throughout the country, comprising every segment of the industry”—is concerned, to put it mildly, about the California requirements for heavy-duty trucks that go into effect in January.

And during testimony to the Senate Environment and Public Works Subcommittee on the future of clean vehicles on April 19 Andrew Boyle, ATA first vice chair and co-president of Massachusetts-based Boyle Transportation, made several points regarding the challenges of a switch to full battery electric trucks. And whether it is available power for recharging, the weight of the batteries and the consequent reduction of weight of the load, or the time needed to recharge, the trucking industry thinks there are issues that need to be addressed.

This is a big deal.

Arguably the Toyota fuel cell kit isn’t the complete solution. But it is a solution.

Toyota is putting it into production later this year in Georgetown, Kentucky, for customers who are looking for a diesel alternative.

///

Moon Mobility

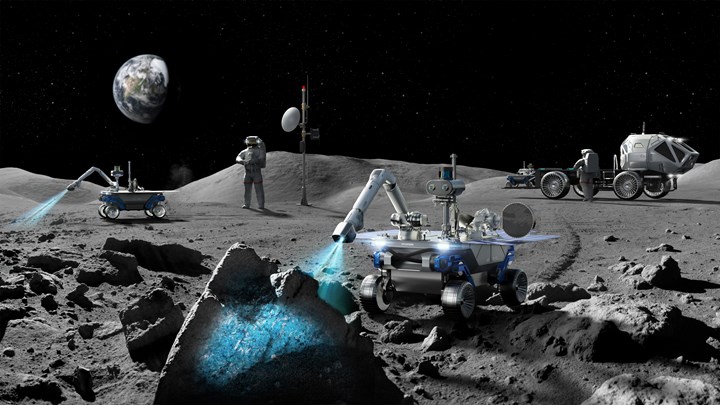

South Korea is planning flights to the Moon, so Hyundai is working to produce a lunar rover that will perform scientific experiments when it arrives there. (Image: Hyundai)

“In the future, countries with a space vision will lead the world’s economy and will be able to solve the problems that humanity is currently facing.” That, according to SpaceNews, is part of a speech delivered last fall by South Korean president Yoon Suk-yeol. To that end, the South Korean government has increased its budget for its domestic space industry in 2023 to $674-million, a 19.5% increase over 2022 spending.

Part of the spending will go toward the development of the KSLV-3, a carrier rocket, that is planned to be complete in 2030.

SpaceNews also reports that South Korea plans to use the new rocket to launch a robotic lunar lander by 2032.

All of which goes to make it more understandable while Hyundai Motor Group announced last week that it has begun the construction of the initial development model for a lunar explorer mobility rover.

One interesting aspect of this rover is that technologies—from sensors to suspension—that are deployed on terrestrial Hyundai and Kia vehicles are being purposed for use on the Moon. (Presumably modified, but the fundamentals are there.)

Partnering

Hyundai is coordinating its efforts with a consultative body that comprises Korea Astronomy and Space Science Institute (KASI)—which is the lead on the KSLV-3 rocket, Electronics and Telecommunication Research Institute (ETRI), Korea Institute of Civil Engineering and Building Technology (KICT), Korea Aerospace Research Institute (KARI), Korea Atomic Energy Research Institute (KAERI) and Korea Automotive Technology Institute (KATECH).

Hyundai is developing the lower part of the rover—the section that drives—while the upper section will carry scientific equipment. Presumably the various research institutes will be the ones in charge of the top part.

The goal is for the lower section to be a platform that will be capable of having various types of top hats deployed.

The solar-powered, autonomous rover is expected to weigh 70 kg (154 pounds).

The first model will be complete in the second half of 2024 and one ready for the Moon by 2027.

Yong Wha Kim, Executive Vice President, and Head of R&D Planning & Coordination Center of Hyundai Motor and Kia:

“The creation of the lunar exploration mobility development model not only reflects this goal, but also shows our ambition to achieve tangible results in the face of significant challenges. With the rover’s development, we are moving beyond land, sea and air mobility to expand into space mobility.”

///

Car Talk: The Generative AI Approach

SoundHound, a company that develops software for vehicular voice-enabled interfaces for an array of global OEMs, has been involved with AI since the mid-00s.

With all of the attention that has been activated by things like ChatGPT of late, the folks at that company must finally feel like they’ve arrived.

And that their approach has been validated.

Not surprisingly, the company has just launched a new product, SoundHound Chat AI for Automotive.

And to help underscore the suitability of the product had a third-party-conducted survey taken April 5 to 16.

Among the findings:

- “50% of all regular drivers said they would be likely or very likely to use an in-car voice assistant with Generative AI capabilities.” Hmm. . .doesn’t this mean 50% wont?

- “75% of regular drivers who frequently use in-vehicle voice control said they would be likely or very likely to use an in-car voice assistant with Generative AI capabilities.” Presumably, those who usually use voice control probably don’t think a whole lot about what’s powering it, only if it works. And why would 25% of regular users of voice control not use it?

- “Over half of (57%) regular drivers under 35 said they would be likely or very likely to use more sophisticated in-vehicle voice technology, with ChatGPT-like responses.” Wouldn’t one assume that younger drivers would be more tech-comfortable at a somewhat higher rate? What’s with the other 43%?

- “Almost a third (28%) of drivers who currently rarely or never use their in-car voice assistant would be likely or somewhat likely to use it, should they be able to access Generative AI.” This sounds like a response of “Yes, I have an in-car voice assistant that I never use, but if it is installed I might give it a try because everyone is talking about Generative AI.”

///

Buy a Mercedes. Get a Scooter!

Get the special edition Mercedes EV sedan and an EV scooter is yours for a year. (Image: Mercedes)

It was recently pointed out to me that last week’s edition had considerable coverage of scooters.

And although this is ostensibly about the Mercedes EQS 580 4MATIC Sedan City Edition—a vehicle that will be available exclusively in the greater Los Angeles area in a quantity of 150 units—it is also about a scooter.

The EQS 580 is an electric vehicle. So while those with a new EQS that isn’t a City Edition have the same standard two-year unlimited 30-minute charging session on Electrify America’s DC network, the City Edition adds a promo code for a free ChargePoint Home Flex charger, and because that charger won’t install itself, a credit of up to $1,000 with Qmerit.

And because that evidently isn’t enough, there is also a $250 credit for the use of public charging on the ChargePoint network.

(Some of you may remember when dealers would provide new car buyers with a gas card incentive. This is like that but an exponential increase.)

What About the Scooter?

And because sometimes the owner of the EQS 580 4MATIC Sedan City Edition just doesn’t want to take the car out, there is a one-year, all-access subscription for the Unagi Model One Voyager, a scooter.

This is a premium scooter with such features as solid-rubber wheels, a machined aluminum deck with embedded silicon on the top surface for grip, magnesium alloy handlebars, and Toray carbon tubes. The scooter is propelled by a 250-W motor in each wheel.

It has a range of up to 25 miles.

The Mercedes EQS 580 4MATIC Sedan City Edition is good for about 340 miles.

Perhaps the scooter is quicker than the car in negotiating some downtown LA traffic.

\\\

RELATED CONTENT

-

GM Develops a New Electrical Platform

GM engineers create a better electrical architecture that can handle the ever-increasing needs of vehicle systems

-

FCA Opens the Door to The Future

FCA introduced a high-tech concept vehicle today, the Chrysler Portal, at the event previously known as the “Consumer Electronics Show,” now simply CES.

-

Honda Re-Imagines and Re-Engineers the Ridgeline

When Honda announced the first-generation Ridgeline in 2005, it opened the press release describing the vehicle: “The Honda Ridgeline re-defines what a truck can be with its true half-ton bed payload capability, an interior similar to a full-size truck and the exterior length of a compact truck.” And all that said, people simply couldn’t get over the way there is a diagonal piece, a sail-shaped buttress, between the cab and the box.

.jpg;width=70;height=70;mode=crop)