on Electrolyzers, the Corolla Cross, Management Thinking Tips, Autonomous Speed Record & More

Bosch is investing in hydrogen production equipment. . .Toyota’s Corolla Cross. . .Roger Martin on thinking. . .Autonomous speed record. . .and more. . . .

Bosch Using Mass Production for Electrolyzers

Bosch is deploying automotive-derived mass production techniques for the development of electrolyzers to produce green hydrogen. (Image: Bosch)

As billions of dollars and euros are being spent by OEMs and battery companies on building out lithium-ion battery production and chasing the materials being needed to produce them, it is notable that Bosch has announced it is investing 500 million euros between now and the end of the decade on developing and producing electrolyzers for the production of green hydrogen.

(“Green”? The power used in the production of the hydrogen is sourced from photovoltaics or wind power.)

Although Bosch sees the demand for green hydrogen in a variety of applications—from steelmaking to private houses—the company is assigning the development of the electrolyzers to its Mobility Solutions business sector.

“Two key factors are involved in ramping up hydrogen production: speed and cost. This is where we can play to our strengths, thanks to our expertise in mass production and our automotive know-how.”-- Dr. Markus Heyn, member of the board of management of Bosch and chairman of the Mobility Solutions business sector.

Stacks & Cells

An electrolyzer’s key component is the stack. A stack is a series of hundreds of individual cells. The cells split water into hydrogen and oxygen using electricity. A proton-exchange membrane (PEM) is used during the chemical reaction.

(In a fuel cell, the hydrogen and oxygen are combined to create electricity; a PEM is used there, too.)

Bosch is working with other companies to develop a “smart module” that will include the stack with a control unit, power electronics and sensors.

These modules can be combined as needed in order to scale output.

What’s more, they’ll be connected to the Bosch cloud to monitor performance.

Bosch plans to produce the smart modules at plants in Germany, the Netherlands, Austria and the Czech Republic. Sooner rather than later.

The Objective

“We cannot afford to delay climate action any longer, so we aim to use Bosch technology to support the rapid expansion of hydrogen production in Europe.”--Dr. Stefan Hartung, chairman of the board of management of Robert Bosch GmbH.

And as the EU adjusts its energy supply in light of the Russian invasion of Ukraine, alternatives like hydrogen are all the more important.

Between now and 2030 the demand for hydrogen in the EU is expected to be some 10 million metric tons per year.

(To put that into some context, know that one kilogram of hydrogen has, according to the U.S. Dept. of Energy, about the same amount of energy as one gallon of gasoline. So while Bosch is talking about applications where other types of fuel are used (e.g., natural gas), even a fraction of that hydrogen being used for powering vehicles wouldn’t be trivial.)

///

2022 Toyota Corolla Cross XLE AWD

Views of the 2022 Toyota Corolla Cross. (Image: Toyota)

Someone asks how you are feeling.

“Fine.”

That’s not “great,” “outstanding” or “the best.”

But it’s not “bad,” “meh” or “off my game.”

Just fine.

There’s nothing wrong about it.

But there’s potentially a bigger upside.

The Corolla Cross is fine.

One of the things about the Corolla Cross, a crossover that launched in late 2021 with the name of a vehicle that has been sold well over 50 million times since it debuted on the world market in 1966, is that the designers and engineers have secreted “Easter Eggs” in various parts of the vehicle.

These are either the words “Corolla Cross” or the stylized sketch consisting of three lines representing the bodyside placed in unexpected places, such as within the rear taillights and on the plastic door trim on the passenger’s side by the sideview mirror.

These are ostensibly deployed in order to provide a sense of “fun” for the vehicle that slots in the Toyota showroom between the C-HR and the RAV4.

The first is the vehicle with an acronym that is sometimes said to signify “Coupe-High Roofline,” given its, well, somewhat sweeping roof on a CUV-ish base, accounting for the “high”(with roof rails, the height is 61.6 inches, so it isn’t like there would be any worry about fitting it into a garage). The Toyota verbiage is “Coupe High-Rider,” which isn’t right in my estimation for no other reason than the hyphen is in the wrong place.

Then there is the RAV4, which is to compact SUVs what the Ford F-150 is to light-duty pickups. RAV4 owns that space.

Standout?

So one might think that with the Corolla Cross Toyota would do something that would make the model a standout in a category that includes competitors such as the Mazda CX-30, Hyundai Kona, Chevy Trailblazer, and Kia Seltos.

But beyond the hidden Easter Eggs, the Corolla Cross’s unique selling proposition is that it is a Toyota.

There really isn’t a whole lot of character to this crossover. It looks like a small crossover. [Shrug.]

It is fitted with a 2.0-liter, 169-hp engine and a continuously variable transmission. Pulling out of a subdivision onto a throughfare, when acceleration is required, leads to a feeling that there isn’t a whole lot of there there. Which is not a good experience. And I was in a version with the optional AWD, so one would imagine there might be a bit more pep in the proverbial step.

25.5 cubic feet of cargo space are behind the second row, and as I have used a Costco run as something of a metric, I can say that it acquitted itself well in that regard.

The interior is tidy, but there are broad surfaces of undifferentiated plastic (well, there is differentiation in the form of molded-in thread stitches and the obligatory graining) that really call out for some styling.

The Corolla Cross is to small crossovers what vanilla ice cream is to frozen desserts.

As it turns out, vanilla is the second-most popular flavor in the U.S. (chocolate is number one), so perhaps that is OK for the crossover.

But I would think that with the array of competitors that the Corolla Cross is up against, a bit of syrup or a cherry on top would be a useful thing to have.

///

Think About It

Your existing thought models may not be as useful as you think. (Image: Harvard Business School Press)

In Thinking, Fast and Slow Daniel Kahneman writes how there are two ways we think. Just look at the words following the comma.

Fast thinking is essentially automatic. It makes use of what we think we know. Because the brain likes not having to work all that much, fast thinking dominates a lot of what we do.

Slow thinking is, well, thinking.

That distinction came to mind when reading A New Way to Think: Your Guide to Superior Management Effectiveness by Roger L. Martin (Harvard Business Review Press; $30), professor emeritus at the Rotman School of Management at the University of Toronto and has spent time as a strategy advisor to companies including Ford.

Martin writes that most organizations have models as to how things are done, and these models are what people use because they “are quicker and easier.” Faster.

And sometimes they don’t work so well for people: “the poor results weren’t down to their not working diligently enough in pursuit of their goals; it was because the model that guided their actions wasn’t up to the task.”

In other words, the quick decision to use the existing model led to work that didn’t accomplish what needs to be realized because the model isn’t what’s really relevant.

Think Again

Martin also points out that customers tend to think fast: “an important truth about customers: the familiar solution usually trumps the perfect one.”

This, I think, is going to be a real challenge as companies begin to put on the market electric vehicles, which are not particularly familiar to most people. Ford is probably doing the right thing by taking an existing F-150 and transforming it into the Lightning because the ICE version is familiar.

Or as Martin puts it: “My argument is that sustained performance is achieved not by always offering customers the perfect choice but, rather, by offering them the easy one.”

Using an example from consumer products (Martin was a close advisor to former Procter & Gamble CEO A.G. Lafley), he points out what the lazy brain does when it comes to deciding what product to choose: “Given a choice, it would like to do the same things again and again. If the mind develops a view over time that Tide gets clothes cleaner, and Tide is available and accessible on the store shelf or the web page, the easy, familiar thing to do is to buy another bottle of Tide.”

So if the F-150 has been the best-selling pickup in the U.S. for the last 45 years, then the easy thing may be to buy another, even if it is electric.

Provocative

Martin has some provocative ideas in A New Way to Think, such as why strategy development needs to be rethought: “Conventional strategy-making tends to focus on problems or issues, such as declining profits or market share. As long as this is the case, the organization will fall into the trap of investigating data related to the issues rather than exploring and testing possible solutions.”

His alternative: people involved in developing strategy must be required “to define two mutually exclusive options that could resolve the issue in question. Once you have framed the problem as a choice—any choice—your analysis and emotions will focus on what you have to do next, not on describing or analyzing the challenge.”

Readers of David Allen’s Getting Things Done will recall that identifying the next action is critical to, well, getting things done.

Think about it.

///

Setting a Speed Record Sans Driver

Record-setting autonomous race car and team members of PoliMOVE who helped make it happen. (Image: IAC)

“We were running a car operating on algorithms alone, where precision is paramount, and any small prediction error could have created a completely different outcome.”

That’s Prof. Sergio Savaresi, team lead of Politecnico di Milano.

The professor is referring to a Dallara AV-21—an autonomous vehicle that is part of the Indy Autonomous Challenge (IAC).

It was programmed by team PoliMOVE, which includes members who go to school at the university in Milan where Savaresi teaches, as well as students from the University of Alabama.

And the outcome, achieved on a runway at Space Florida’s Launch & Landing Facility at Kennedy Space Center, is a land speed record of 192.2 mph.

A speed record for an autonomous vehicle.

IAC participants include students from 21 universities from nine countries.

The IAC competitors actually ran at the Indianapolis Motor Speedway last October, which puts them in association with amazing. . . drivers.

TUM Autonomous Motorsport, from the Technische Universität München (TUM), won the first competitor at the Brickyard, achieving the fastest two-lap average speed around the oval of 135.944 mph.

The goal of IAC isn’t to get cars to go fast in straight lines or around ovals.

Rather, its about advancing tech for commercial autonomous vehicles and advanced driver assistance systems (ADAS) while developing next-gen STEM talent among universities around the world.

///

Transitioning Gas Stations to Electricity Outlets

Bernard Looney (left), bp CEO, and Herbert Diess, VW Group CEO, at a bp Aral station using the first VW-developed Flexpole fast charger. There will be 3,999 more in Germany and the UK over the next two years. (Image: VW)

“Our goal is to ensure that an electric vehicle is capable of being a customer’s primary car – without any compromises. That is why we are building a complete charging eco-system, with residential charging solutions and a rapid expansion of the fast-charging infrastructure required for mobile charging, as well as competent advice, comprehensive charging tariffs and the right fleet solutions for business customers.”

That’s Elke Temme, Head of the Charging and Energy business area at Volkswagen Group Components and CEO of Elli.

(Elli? It is a provider of energy and charging solutions that’s part of the Volkswagen Group.)

While all OEMs have some sort of charging offering for customers of electric vehicles, there are a couple things to note about what Volkswagen Group (as in Cupra, Seat, Skoda, Volkswagen, Volkswagen Commercial Vehicles, Audi, Bentley, Ducati, and Lamborghini) is doing in Europe:

- The company has developed a 150-kW charging unit. It has two charge points and an integrated battery storage system. The Flexipole charger can be connected to a low-voltage grid so there isn’t a need for extensive construction work to put it in place.

- While it is partnering with various charging companies, last week VW Group and bp announced a strategic partnership in which Flexpole chargers will be deployed at bp stations. There will be 4,000 charge points established over the next two years at bp facilities in Germany and the UK. By the end of 2024 there will be as many as 8,000 in Europe.

Two points:

- VW is Europe’s largest OEM. It plans to have 70% of its sales battery electric vehicles there by 2030.

- bp plans to have more than 100,000 EV charge points established globally by 2030.

If VW EV sales go up, bp gasoline sales go down. If chargers aren’t readily available, there will be fewer VW vehicle sales.

One hand washes the other.

///

Follow the Money

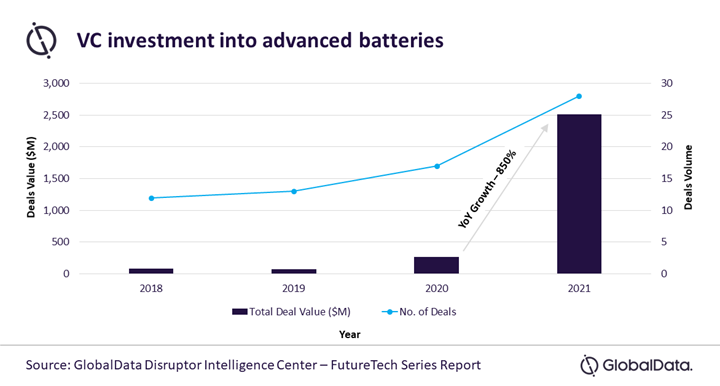

A non-trivial amount of VC money is going to batteries. (Image: GlobalData)

While on the subject of charging. . .

Venture capitalists (VCs) are nothing if not interested in the success of the firms they invest in so they’ll make more when they exit.

So what is going on in the battery space is notable vis-à-vis VCs in important.

“Big deals from VC investors are pushing forward the advanced batteries funding to a new high. The major focus of such deals is primarily to accelerate the commercialization of lithium-powered batteries that exhibit high energy density, superior performance, increased safety, and are cost-effective.”-- Prasad Kakade, Senior Disruptive Tech Analyst at GlobalData

An 850% year-over-year growth in VC investments in lithium batteries.

While not all of the batteries are destined for electric vehicles, another observation from Kakade is notable:

“In the coming years, the VC interest in EV battery startups seems to be far from running dry. The interest is likely to be driven by clean energy requirements and the growing demand for zero-emission, all-electric cars. With new opportunities flocking to these areas, battery materials with minimal environmental footprint and sustainable designs would create a new race for battery supremacy.”

One wonders. . .

With the billions of investments being made by OEMs and non-startup battery companies, to what extent is there protection in those plants should one of these EV startups come up with a completely different battery chemistry. . .?

///

Innovative Approach to Unsprung Weight

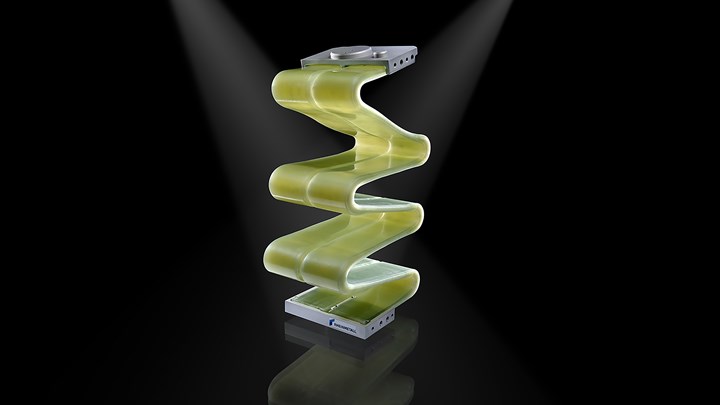

Composites replace metal in this spring development. (Image: Rheinmetall)

One of the things that doesn’t get much attention when it comes to electric vehicles (EVs) is that like traditional cars, crossovers and trucks they have traditional things ranging from stampings to seats to chassis components, too.

It’s not all about lithium-ion batteries.

And one of the things that is really important for EVs is reduced mass. Batteries are heavy.

Consumers generally want longer ranges from their vehicles.

Which means bigger batteries. Bigger batteries are heavier. So it takes more energy to move them. Which means. . .a vicious cycle.

So there is the pursuit of lightness without performance compromise.

Case in point: a new glass fiber suspension spring developed by Rheinmetall that, according to the company, has “a weight advantage in the unsprung mass of up to 75% compared with conventional steel coil springs.”

Another advantage cited for the fiber glass springs compared with steel: corrosion resistance.

The engineers who developed the suspension spring focused on:

- Pitch and roll stability

- Damping

- NVH

The spring is designed to fit in the same space as a conventional coil spring.

///

RELATED CONTENT

-

The Koenigsegg Jesko Has An Amazing Engine

It is hard to believe that this is a vehicle in “serial” production with such extraordinary powertrain performance

-

Increasing Use of Structural Adhesives in Automotive

Can you glue a car together? Frank Billotto of DuPont Transportation & Industrial discusses the major role structural adhesives can play in vehicle assembly.

-

Multiple Choices for Light, High-Performance Chassis

How carbon fiber is utilized is as different as the vehicles on which it is used. From full carbon tubs to partial panels to welded steel tube sandwich structures, the only limitation is imagination.

.jpg;width=70;height=70;mode=crop)