on Fuel Cells, Kia Design Wins, Big German Vehicles, EV Charger Challenge, & the Mazda3

Advancing fuel cell tech, how Kia cleaned up at the 2022 iF Design Awards, the new BMW X7 and materials, two out of three vehicles on Mercedes’ large electric vehicle platform, EV charging survey results, and why Mazda is a clever company

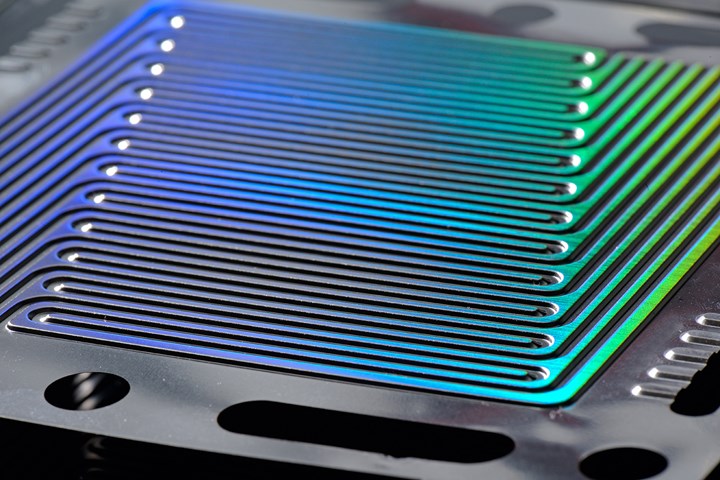

Hydrogen + Lasers

A bipolar fuel cell plate designed by Dana Victor Reinz with ultrashort pulse (USP) microstructuring. (Image: Fraunhofer ILT)

Although there is presently a greater focus in the European Union to find energy resources that don’t come from Russia, it turns out that there have been a number of researchers in Germany who have been working on the use of hydrogen as a means by which to achieve power and reduce CO2 emissions for some time now.

Even researchers who are involved in laser technology.

So to that end, the Fraunhofer Institute for Laser Technology (ILT) is opening a 300-square meter hydrogen laboratory in Aachen on May 5.

The objective?

To “advance the cost-optimized and demand-oriented series production of fuel cells.”

Note that although it is going to be staffed by researchers and scientists, the objective is to create production capability.

One area of interest is the production of metallic bipolar plates. Lasers are used to selectively structure and coat the plates, which are used in fuel cells, so as to improve efficiency and functionality.

Quotable

Notes Dr. Alexander Olowinsky, head of the Micro Joining Group at Fraunhofer ILT, “We could work with component manufacturers for fuel cells as well as with partners who want to produce manufacturing technology such as scanners or tools for process monitoring or with those who want to test beam sources.”

Olowinsky adds: “The facilities also cover issues we have encountered in ongoing investigations with customers. We expect to make significant progress because the new machines have much lower restrictions in terms of speed, accessibility and controllability.”

Observation

Although it may seem as though the auto industry is all-in on battery electric vehicles, there are still companies—Toyota, Hyundai, Honda, BMW, GM—that are continuing the development of fuel cells for passenger and commercial vehicle applications.

And it is worth noting that there are stationary applications for hydrogen fuel cells, too. General Motors announced in January, for example, that its Generation 2 HYDROTEC fuel cell power cubes can be used in a number of applications, ranging from powering military camps to outdoor concerts, and even replace grid-sourced electricity for homes and commercial buildings during power outages.

///

///

Kia and the 2022 iF Design Awards

The award-winning IP in the Kia EV6. (Image: Kia)

Most companies would be happy to win one iF Design Award*. What you’re looking at here represents two awards that were received by Kia in the 2022 competition that had 5,424 entries—on the short list.

One of the awards is in the “Product Interface” category for the curved display that crosses the IP space in the company’s EV6 all-electric crossover vehicle.

The judges, among other things, took note of the cluster design in the 12.3-inch TFT center display that foregoes the round gauge faces that are now the tradition in vehicles powered by internal combustion engines. The UX designers at Kia went for a new graphic approach.

Another nod was given by the judges to the interface’s green and violet color palette, which they suggest further underlines the advanced nature of the EV6.

The second thing you can see in the photo that won an award is the textured surface on the IP (most apparent on the right side of the photo, but you can note that it runs below the display). This surface material is “GEONIC,” which was developed in collaboration with Korean company Kolon. The award category is “Car Interior Design Material.”

The material is developed with layers of polyurethane. There is a base, pattern, color, dimensioning, then finish. The result is a three-dimensional textured surface with an advanced-tech appearance in the EV6 application.

But Wait. . . !

Most companies would be happy with one iF Design Award.

Kia didn’t receive just two 2022 iF Design Awards.

It received two more. A total of four.

There is one for the EV6 itself, in the “Automobiles/Vehicles” category.

The crossover deploys Kia’s new “Opposites United” design language, which combines classic cues with advanced technology.

In other words, this is not some sort of Retrofuturism, but a melding of the two approaches, one from the past and one, arguably, of the future, to create something notably distinctive.

And the other iF Design Award that Kia received is in the “Shops/Showroom” category for its “EV6 Unplugged Ground” space in Seoul’s Seongsu neighborhood, which is sometimes compared with Brooklyn for its youthful vibe.

The showroom space is not just about the vehicle, but also focuses on advanced mobility, recycling and other au courant subjects.

Four design awards. One vehicle. Quite an accomplishment.

==

* iF International Forum Design GmbH was established in 1953 with six guidelines:

- To identify, support and promote good design

- To raise awareness of design among the public and the role it plays in our lives

- To help companies integrate design into their long-term strategies

- To safeguard the role of professional designer and boost awareness for this job profile

- To effect social change through design

- To support talented young people and create a public platform for young designers

The awards were established in 1954 and are considered one of the pre-eminent design awards on the planet.

///Something Else About the New BMW X7

The new BMW X7. Clearly makes a statement. (Image: BMW)

By now you’ve probably seen/read about the new BMW X7, especially about what BMW describes as its “extensively revised front end” that ensures it “makes a potent visual impact.”

Depends on how you define “potent,” I guess.

It is a big vehicle—203.3 inches long, 78.7 inches wide, 71.1 inches high—so there’s really no missing it.

What could be easy to miss but shouldn’t be are the efforts being made for sustainability for the X7:

- It is manufactured at the BMW Group Plant Spartanburg [SC]. Power for vehicle production at the plant is generated from renewable sources.

- Air ducts for the X7 brakes, radiator and rear seating are made with 50% recycled plastics.

- Cable channels and the luggage compartment are made with 100% recycled plastics.

- The floor mats use Econyl, a “regenerated nylon” thread that is sourced from things ranging from discarded carpets to old fishing nets. According to Aquafil, the Italian company that produces it, the “regenerated nylon is exactly the same as fossil [fuel]-based nylon.”

- The standard seating surface material for the X7 xDrive40i (it features a 375-hp inline six and a 48-V mild hybrid system) is “Sensafin,”a leather-like vegan material.

Every little bit helps. Especially for big vehicles.

///

Some Things About the Mercedes EQE

The Mercedes EQE has a coefficient of drag as low as 0.22. (Image: Mercedes-Benz)

The second model based on EVA2, Mercedes’ architecture for large electric vehicles, is the EQE.

The first is the flagship EQS sedan.

(And last week they announced the third, the EQS SUV, below.)

The EQE, like the EQS, is a sedan. However, it, unlike the EQS, has a conventional trunk lid.

Perhaps this is because it is “the new business avant-garde,” in the company’s description. Businesspeople tend to have luggage and binders and samples and the like, so presumably the trunk rather than a hatch is the preferred approach for conveying that cargo (close the lid and no one can see what’s back there).

Materially

It is worth noting that the trunk lid, doors, hood, and front fenders of the EQE are made with aluminum. (Mass is a big concern with EVs.)

However, structurally the EQE is primarily steel, including hot-formed, ultra high-strength steel.

The EQE also uses steel from Salzgitter AG that is 100% recycled. (Green credentials are a good thing when piloting a vehicle that is 195.4 inches long, 75 inches wide and 58.7 inches high—even if it is an EV.)

For side impact protection, steel and aluminum are used. There is a steel outer with a deformable aluminum insert. The element is engineered to help minimize damage to the battery modules in the event of a side impact.

Electrically

Speaking of the batteries, there are 10 cell modules in the EQE 350+ model. The battery chemistry of the lithium-ion cells consists of nickel, cobalt and manganese in a ratio of 8:1:1 (a.k.a., a low-cobalt chemistry; Mercedes is working to eliminate cobalt through what it calls “the use of innovative post-lithium-ion technologies.” It isn’t there yet.)

The range for the EQE on the WLTP cycle is from 352 to 406 miles for the rear-drive sedan with it 215-kW motor.

Although the EQS is being produced at the new Factory 56 in Sindelfingen, the EQE is being built at the Mercedes plant in Bremen. It is being assembled on the same line as the C-Class, the GLC, the GLC Coupé and the all-electric EQC.

Fragrantly

There is “active fragrancing” for the EQE. And a special fragrance developed for the vehicle: “No. 6 MOOD bittersweet.”

That’s “bittersweet” as in “dark chocolate.”

As for the “No. 6,” that’s somewhat more cryptic.

It references the original "Mercédès Electrique" vehicles, Mercedes’ first EVs, which were launched in 1906.

///

OK, what about the EQS SUV?

"With our EQS SUV, we are presenting our first all-electric SUV on the new architecture. The futuristic design consists of an emotionally appealing integration of surfaces and shapes, and the seamless transitions reflect the style of our company. This creates an aerodynamic and modern look. Together with the innovative, progressive SUV proportions, we are completely redefining SUV luxury of the future."--Gorden Wagener, Chief Design Officer Mercedes-Benz AG (Image: Mercedes)

Briefly:

- Either rear or AWD. The 265-kW permanently excited synchronous motor is standard on the rear axle of all versions. The 4MATIC vehicles have either a 265- or 400-kW motor on the front axle, too. (Fun fact: the Mercedes for its electric drive train is “eATS.”)

- There is a 12.3-inch OLED screen for the front passenger. It is part of the available three-screen MBUX Hyperscreen that stretches from A-pillar to A-pillar (55.5 inches). The passenger screen portion allows the display of “dynamic content” in some European countries. But the real-time dynamic content going outside the vehicle (a.k.a., “the real world”) is what the driver needs to be concentrating on. The EQS SUV has an interior camera system that keeps an eye on the driver’s eye. Should the driver look at the passenger’s dynamic content, the screen is automatically dimmed. Presumably the front-seat passenger, if for no other reason than wanting to watch that content, will tell the driver: “Eyes on the road!”

- This is a big vehicle: 201.7 inches long, 77.1 inches wide, 67.3 inches high, and with a 126.3-inch wheelbase. To assure the comfort of the passengers, it is configured standard with two roomy rows. A third row is an option.

- The second row is electrically adjusted. Should it be put in the full-rearward position there is 22.7 cubic feet for cargo. If the second row is moved all the way forward, that goes to 31 cubic feet. Mercedes calibrates this in a more meaningful manner: five passengers and “24 crates of mineral water or four golf bags.”

- Unlike the EQE, this is a steel-intensive vehicle: high-strength, press-hardened, hot-stamped. Like in the EQE there is an aluminum insert in the steel side sills. Aluminum extrusions are also used for the battery (107.8-kWh lithium-ion) case.

- Range? About 373 miles. Depending.

- The EQE is built in Bremen. The EQS Sedan Sindelfingen. The EQS SUV? Tuscaloosa. (The batteries for the EQS SUV are coming from a battery plant Mercedes opened last month in nearby Bibb County.)

- Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG, Production and Supply Chain Management: "The global Mercedes-Benz production network is digital, sustainable, efficient and flexible. The Tuscaloosa plant, with its highly skilled and motivated U.S. workforce, will be a critical factor in the continued success of Mercedes-Benz; and we are proud that our new electric SUVs will also be built in Alabama for global markets."

///

Where’s the Charging Station?

One of the reasons Volta is interested in setting up chargers is because it has a model that allows digital advertising on the dual 55-inch screens on those chargers. Yes. that is a charger. (Image: Volta)

Volta is a company with electric vehicle charging stations across the U.S.

Presently there are 2,438 chargers in its network.

Volta recently conducted a study to determine the barriers beyond price and range anxiety that need to be overcome for greater consumer acceptance of EVs.

One not entirely surprising finding:

- 75% of EV intenders say convenience to chargers is the number-one reason why they haven’t moved from intending to buying. That is 5% higher than the issue of price.

But here’s something that is fairly surprising:

- 42% of Americans have never seen an EV charging station. (Well, even the Volta map of the locations of its chargers shows that there are large swaths of the U.S. blank with 27% of its chargers in California.)

And possibly a bigger kicker:

- 27% of EV intenders haven’t seen a charger.

Ask yourself this:

- What percentage of people haven’t seen a gas station?

And a quarter of those who say they might buy an EV haven’t seen a charger?

///

EV Power on the Go

What appears to be a white suitcase on the left side of that structure is actually an EV charger that is ordered via an app, rolled to the vehicle in need of charging, then returned to its bay when the task is complete. (Image: ZipCharge)

While on the subject of charging. . . .

ZipCharge, a British company, has launched GoHub, a configuration of distributed charging units that can be located on city streets, parking lots or other places where there is easy access for EV drivers.

Each GoHub structure is sized to fit in a single parking spot.

What makes GoHub different from other EV charging setups is that there are chargers docked within the structure. Users, who access a charger via an app, removes it from the GoHub. The charger is configured like a wheeled suitcase, retractable handle and all.

The charger is wheeled to where the vehicle is located. Once the charge cycle is complete, the unit is returned to a bay within the GoHub.

The Approach

The chargers come in difference capacities (4, 6 or 8 kWh). The charging model that the company supports is to charge little but often, “grazing,” in effect. (You’re not going to fill an empty battery with one.)

Not only is the approach one of convenience for the customers (those who live in places where there is only street parking or structures without charging stations) but the ZipCharge says the cost structure for a GoHub is significantly less for municipalities who are looking for creating a charging infrastructure.

///

2022 Mazda3 2.5 Turbo AWD Hatchback

The Mazda3: The sort of performance that is beyond the norm, as is the attention to detail and execution. (Image: Mazda)

The Saturn manufacturing complex opened in Spring Hill, Tennessee, in 1990. The facility had an array of things that were out of the ordinary at the time, ranging from self-directed work teams to lost-foam casting for the engines.

But when touring the new final assembly operation there was something absolutely stunning in an industrial facility: 12 x 14-foot platforms made of birch wood upon which the vehicles-in-becoming were fixtured, not nose-to-tail as on typical assembly lines (there was nothing typical about Saturn: “A different kind of car. A different kind of company”), but side-to-side.

The assemblers would ride on these moving platforms to perform their tasks. This approach was said to provide a distinct ergonomic advantage for the assembly associates vs. walking along the assembly line on concrete floors all day.

DIY(ish)

A few months later in 1990 I happened to visit the Mazda manufacturing complex in Hiroshima.

I spent some time talking with the head of assembly operations, which had relevance because back then Ford owned a controlling interest in Mazda (it has since sold its shares) and the second-generation Escort was based on the platform used for the Mazda 323, which I was to see being built.

The tour started with a look at a map in a dark foyer. The young man hosting me pulled a string to turn on a fluorescent fixture. He explained what was where in the assembly facility. He turned off the light when we began our walk.

It struck me then that this was an entirely different place than the one I’d visited in Spring Hill as the light in that plant—and probably all others—would have been on all the time. And I doubt that the switches in Spring Hill would have been connected to strings.

When we reached the 323 final assembly line I saw something that I will not forget as it couldn’t have been a bigger contrast than what I saw at Saturn.

The workers had created a system that allowed them to move along with the vehicle during the assembly.

While this may be a slight exaggeration, it was essentially based on a 2 x 4 plank of wood, what appeared to be roller skate wheels and a rope.

It did the job. It was clearly the work of thoughtful line workers, not a cadre of industrial engineers.

(A variation of this that became somewhat famous a few years later was the use of a bass boat seat for assemblers on the line at the Toyota Georgetown Plant.)

How Its Done

All of this is to get to the point of the 2022 Mazda3.

This is an exceedingly nice, sporty (the 2.5-lier DOHC, turbocharged engine produces 227 hp and there is a six-speed automatic with sport-shift capability) four-door with a hatch.

It has “G Vectoring Control Plus,” which, when sport mode is selected, makes driving on twisty roads (probably not on your daily drive, but when you can you might as well push it) under better control as it automatically downshifts the transmission under braking and doesn’t perform unnecessary upshifting while in corners. (Said more simply: it keeps the powertrain from feeling jerky.)

The i-Active AWD system allows more—as in three times more—torque to the rear wheels should it be necessary.

Things like that results in, as Mazda used to say, a feeling of “Zoom-Zoom.”

And with the Premium Plus Package there are things ranging from the nice (leather seats) to the notable (there is traffic sign recognition, as in seeing a little image of a stop sign in the seven-inch digital gauge cluster).

The base MSRP is $34,400.

Think about this. A well-handling, well-appointed, turbocharged AWD sedan that has a design that is seriously eye-catching.

And there it is, executed in sheet metal.

I suspect this is accomplished by a company where the culture encourages a whole lot of attention to the small things (e.g., turn out the light when it isn’t being used) and to some clever production engineering (even if it is done by line workers).

There’s plenty other OEMs could learn from Mazda.

RELATED CONTENT

-

Things to Know About Cam Grinding

By James Gaffney, Product Engineer, Precision Grinding and Patrick D. Redington, Manager, Precision Grinding Business Unit, Norton Company (Worcester, MA)

-

On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.

-

Multiple Choices for Light, High-Performance Chassis

How carbon fiber is utilized is as different as the vehicles on which it is used. From full carbon tubs to partial panels to welded steel tube sandwich structures, the only limitation is imagination.

.jpg;width=70;height=70;mode=crop)