Yes, Hybrids Still Matter

Hybrids—mild, full and plug-in—are likely to continue to be important as the automotive industry makes the transition to full electrification. An examination in three parts.

#hybrid

Consider this timeline:

- September 2018: General Motors announces at $28-million expansion of its advanced battery test lab in Warren, Michigan, to bring the facility to a footprint of more than 100,000 square feet

- March 2019: GM announces a $300-million investment in its Orion Township, Michigan, plant to produce a new Chevrolet electric vehicle (EV), which will join the Chevrolet Bolt EV, already in production at the factory

- December 2019: GM and LG Chem announce plans to build a $2.3-billion plant in Lordstown, Ohio, to produce EV batteries. Construction started on the plant in May 2020

- January 2020: GM announces a $2.2-billion investment in its Detroit-Hamtramck assembly plant to build various all-electric trucks and SUVs. GM has developed a platform to accommodate 19 different battery and drive unit configurations that can be used for vehicles ranging from sedans to work trucks

- April 2020: GM and Honda announce the companies will jointly develop two EVs based on the GM platform and using the Ultium batteries that will be produced in the GM-LG Chem plant

Given all this, it is clear that GM is pursuing a future that is going to be fully electric. In March 2020 GM CEO Mary Barra said, “We want to put everyone in an EV and we have what it takes to do it.” The company plans to have 20 EVs for sale in the U.S. and China by 2023.

GM had made a major statement in December 2010 when it started selling the Chevrolet Volt, a plug-in hybrid vehicle (albeit one described as an “extended-range electric vehicle” as the internal combustion engine acted as a generator in the system). The second-generation Volt was introduced in 2015. And in February 2019, the last Volt was manufactured.

Given that—as well as the fact that other industry giant Volkswagen Group is investing over €33-billion in EVs (product and capacity and anticipates producing 1.5-million EVs per year by 2025—one might well think that hybrid electric vehicles have had their day.

But, that is not the case.

Hybrids still matter. And are likely to for the next decade.

PART 1

Jörg Trampler admits: “I don’t know what the future will be.”

But as the head of the Engineering Center North America, Car Powertrain Technology, ZF Friedrichshafen, he not only has a pretty good notion, but he and his colleagues are working to make it happen. “There is a high likelihood that almost everything will be electric.” Electric as in a full battery electric vehicle with batteries, or an electric vehicle that is based on a fuel cell rather than batteries.

But is it a matter of getting there.

And getting there is going to going to take something of a build-out of product as well as infrastructure.

A Netflix Analogy

He has a personal way of looking at the electrification imperative that has something of a parallel in Netflix. That company was established in 1997. It originally was an online DVD rental company. In 2007 it offered both DVDs and on-line streaming. In 2016 the company put the DVDs in a separate organization, DVD.com, which essentially means that Netflix is a full streaming service.

So Blockbuster is analogous to the internal combustion engine. When Netflix entered the market with DVDs (it has decided to forego VHS rental), that, Trampler says, is like a hybrid: sending DVDs was more efficient than the brick-and-mortar, but there was still the hardware element.

The streaming approach is akin to the electric vehicle. “Why didn’t they have 100% streaming at the start? Because the infrastructure wasn’t there. Modems were too small. No one wanted to wait two days to download a movie.”

Why doesn’t every company have an array of EVs to choose from? Well part of it is infrastructure: It makes little sense for someone to have an electric vehicle if there isn’t the capacity to readily charge it, just as streaming didn’t make a whole lot of sense before there was the bandwidth for consumers to use it.

And familiarity breeds more comfort than contempt: Not everyone wanted to give up their VHS player.

Not everyone is ready to go full EV—even if there is infrastructure.

The 300-mile Challenge

For some reason, many consumers think that a vehicle needs to be traveling at least 300 miles before its energy supply is replenished with a nozzle or a plug. The 300 miles have pretty much become a bogey for EV producers. Anything less is something of a compromise. And consumers will approach—if at all—the reduced range vehicle with trepidation borne of range anxiety.

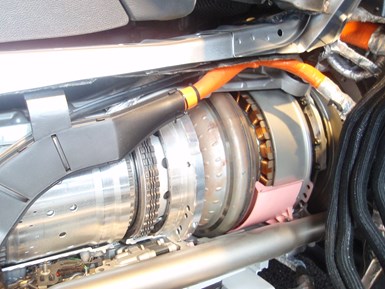

The next-generation 8HP eight-speed automatic that will go into production in 2022 is engineer such that the motor—which provides a maximum output of 160 kW—is integrated into the housing, as are the power electronics. (Image: ZF)

Trampler points out that given the state of battery technology, this means that bigger batteries are required to move mass, which increases the already comparatively high cost of the vehicle, a cost that is largely predicated on the price of the batteries. And as batteries themselves are heavy, the goal of range (“For whatever reason, the 300-mile range comes up all the time. I don’t know why.”) means. . .more batteries.

Or a hybrid powertrain: “The hybrid offers the range when needed”—as in the range of an internal combustion engine—“and can run electrically when wanted.”

To that end, Trampler cites the situation that exists in some European cities, where there are zero emissions zones in the center city. This is a case where a plug-in hybrid can make sense: the driver who lives, say, in the suburbs, drives in mainly using the internal combustion engine, then switches over to full-electric when reaching the border of the zone.

And even for non-European drivers: the range provided by a plug-in hybrid could be sufficient for a daily commute or to run errands while the internal combustion engine is there when it is necessary to take a trip of greater distance.

Say 300 miles.

Transmission Design

A consideration regarding hybrid powertrains is that of packaging. Quite simply: it is an additive design, an internal combustion engine and an electrified system. (Trampler describes another challenge that is encompassed in a word: “Complexity.”)

ZF makes (among other things) transmissions, and Trampler says that one of their ongoing goals is to produce transmissions for hybrids that package the same as those in non-hybrid applications.

ZF has been at this for a while and currently offers an eight-speed longitudinal automatic that integrates an electric motor without greatly increasing the size of the package. In 2022 its fourth-generation eight-speed will go into global production. What is notable about his is that the company has developed an electric motor that is compact (instead of coiled copper wire it uses welded copper bars that are bent—the “hairpin technique” describes this configuration—to maximize density, which means less space is required) and powerful: the maximum power of the motor is 160 kW, continuous output is 80 kW, and it produces 450 Nm (332 lb-ft) of torque.

What’s more, Trampler says they’ve managed to integrate the power electronics into the transmission housing rather than having a separate container (that’s about the size of a shoebox and which requires fewer high-voltage cables, which not only enhances safety but reduces complexity).

One of the challenges the ZF engineers had to address was the heat generated by the electronics because semiconductors generate a lot of waste heat (especially the IGBTs used in high-voltage setups). This heat is managed by integrating the electronics into the refrigerant circuit of the air conditioning system.

A significant space was the development of a hydraulic control unit that uses electromagnetic actuators rather than the electric pressure actuators used in the current eight-speed hybrid transmission: this means the volume of the new hydraulic control unit is 1.8 liters compared with the current 3.1 liters.

The updated, 2021, 7th generation BMW 5 Series is available as a plug-in hybrid. The 530e and 530e xDrive sedans feature a 181-hp, 2.0-liter six-cylinder engine, a 107-hp electric drive unit integrated into the 8-speed transmission and a 12-kWh lithium ion battery. The system provides 288 hp and 310 lb-ft of torque. While hybrids typically mean reduced emissions, they also can provide performance: there is an “XtraBoost” function that provides an additional 40 hp for up to 10 seconds. (Image: BMW)

Trampler admits that the execution of this 4th-generation transmission was “more complex for us,” but it advantageous to the OEM because of the integration and the space savings achieved.

A Little or a Lot

There are two areas of development in the hybrid space that ZF is also pursuing: the 48-volt, or mild hybrid, and the plug-in hybrid. As for the former, the systems are beneficial from the standpoints of being comparatively economical and environmentally beneficial (i.e., reduced CO2 emissions by supplementing or minimally replacing the internal combustion engine).

Currently ZF has a 48-volt system that has a motor—which can be mounted on the crankshaft (P1) or on the input gear shaft (P2)—with a maximum of 25 kW. It can supplement the engine at launch and during acceleration, but it can also provide limited electric range—Trampler says it is sufficient to pull a vehicle out of a garage on electric power.

Then there’s the plug-in hybrid. This is the system that allows the previously mentioned electrical operation in zero-emission zones. Plug-in hybrids can provide full electric driving without range anxiety, and while plug-ins have generally had limited range capacity, that doesn’t need to be the case.

The ZF EVplus is a concept, but it is engineered to show that a plug-in hybrid can provide both performance and range. Not a full EV, but in many cases, full enough. (Image: ZF)

To prove that point ZF developed a demonstrator vehicle, the EVplus, that it introduced last fall. It is a plug-in hybrid BMW 3 Series (the last-gen 330e) that was modified by replacing its 7-kWh battery with a 35-kWh battery. The vehicle uses the ZF eight-speed hybrid transmission. The setup provides 65 kW of continuous power and a peak output of 95 kW. But what is most significant is that the EVplus has a “real-life range” on electric power of about 60 miles.

Not 300 miles. But 20% of the way there—and a gasoline engine that will provide the rest of the distance and then some.

PART 2

Patrick Lindemann, president, Transmission Systems and e-mobility at Schaeffler, makes a point that is rather important, especially in the U.S. market: People don’t want small vehicles, they want big ones. And there is an addendum to that: mainstream buyers are not going to be investing in $60,000 to $70,000 vehicles.

Which goes to the battery electric vehicle today, where there are things like Teslas that may have a low starting price but an elevated sticker price (and let’s face it: the Model S starts high and goes higher), vehicles that are more talked about than purchased by the mass market.

Lindemann points out that to produce an affordable BEV it is likely to be small and light. But as people don’t want small vehicles, they must be made bigger. And in order to get reasonable performance, the battery must be bigger, too, which not only adds mass to the vehicle, but which adds cost.

“Everyone says costs of batteries are coming down,” Lindemann says, “but the cost can only come down significantly if we have a new type of battery.” He explains that the cost of the raw materials in a battery represents about 70% of the total cost. Given that there is little likelihood that raw material costs are going to be significantly reduced at any time (stability alone would be a good thing), that is a fundamental barrier to slashed battery costs.

“I think we will not see that big leap everyone hopes for—the 100-kWh battery for around $5,000—in the next 10 to 15 years unless we have a major invention.”

Which leads to reasonable speculation: “At Schaeffler, we think that by 2030 most vehicles will be still be driven by internal combustion engines with some kind of hybridization, electrification. The pure electric vehicle will still be a small percentage of the market. This is just 10 years from now.”

“Best of Both Worlds”

So from his perspective, it will be the hybrid going forward during the next several years, a propulsion technology that he describes as “the best of both worlds.” There is both driving on gasoline and driving on electricity.

There is also, he points out, an environmental component to this, as well. In places like Europe and China there are regulations targeting emissions and CO2, which hybrids can help address. While the regulations from a federal level have become looser in terms of fuel economy (and by extension, emissions), Lindemann notes that there are California and the CARB states that need to be taken into account, given the considerable amount of vehicle sales those states represent (>40%).

“It is our goal to make environmentally friendly cars that are fun to drive.”

Different Approaches

There are essentially three types of hybrids. There is the 48-volt system. The full hybrid and the plug-in hybrid, with it being essentially the same as the full hybrid except that it has a plug, an on-board charger and a bigger battery. It also tends to have a bigger price tag--$5,000 or more compared to the full hybrid—predicated in large part by the price of the battery.

“What I am seeing is that the full hybrid will be coming stronger for the next several years, helping address emissions in the countries where it is needed. Then, when emissions regulations get tighter, people will increase the size of the battery and put an onboard charger on it and transition some of these vehicles to a plug in.”

As for 48-volt systems, Lindemann says that while they’re certainly not as powerful as a full hybrid, there are benefits provided. “If you have a 20-kW hybrid system, that’s enough power to drive vehicles at lower speeds.” But there are the more likely applications of providing start-stop (which he says needs to be made more seamless when switching because otherwise consumers become annoyed by the jerkiness and shut the systems off) as well as permitting the downsizing of the engine because addition boost is added by the hybrid system.

There is another advantage to 48-volt systems: It is safer for humans in the event that something goes awry, like a loose wire. When it is a 60-volt system, for example, there must be significantly more safety measures put in place, which increases the cost of the system. So the 48-volt system provides performance benefits, a higher degree of safety, and a comparatively lower cost.

Big. Smart.

Because consumers are looking for larger vehicles and because hybridization is exceedingly viable from the standpoint of offering a cost-effective approach to an electrified vehicle (that is, in the context of a full BEV), Schaeffler has been working with companies like Ford and Lincoln. Both the Ford Explorer and the Lincoln Aviator use systems that deploy Schaeffler modules.

The Schaeffler hybrid module as being used for the Ford Explorer Hybrid. It is in the P2 position, located in front of the torque converter. (Image: gsv)

The engine and transmission are separated by approximately 150 mm and a module including an electric motor, disconnect clutch and torque converter is packaged between the two. Not only is there a packaging advantage (with there being very little difference between the dimensions of a hybrid and non-hybrid version) but because of the parallel hybrid configuration, a Ford Explorer hybrid, for example, is capable of towing up to 5,000 pounds.

A technology that seems to be often discussed in the same breath with electrification is automation. Lindemann thinks that automated driving is going to come on faster sooner than others anticipate.

And if they do, hybrids make is feasible: “Autonomous systems need quite a bit of electric power. Even a 48-volt mild hybrid system can deliver the power needed. Up to 20 kW of electric power can be generated while driving, which can be used for the various lidar, cameras and other systems.

“If you had just a standard powertrain that would be very difficult: You can’t put 20 kW through a belt on the front of an engine.”

PART 3

The plan had been for Continental to spin off Vitesco Technologies at its annual shareholders meeting on July 14, 2020. But then COVID-19 occurred, so at the end of April 2020 a decision was made to delay this move until timing is more propitious.

Vitesco Technologies? Yes, perhaps an unfamiliar name. It had been Continental’s Powertrain Division. Which had led some to speculate that the future of powertrains as they have been known are behind us.

But listen to Continental’s CEO Dr. Elmar Degenhart, speaking in relation to the delay of the spin: “Without a doubt, clean drive systems are the value-creating business of the future. We are therefore more convinced than ever that Vitesco Technologies has very good prospects for profitable growth. To make the most of these opportunities, a high degree of entrepreneurial flexibility and thus independence on the highly dynamic powertrain market are required. Although the effects of the coronavirus crisis have temporarily halted the market, the basis for future market growth has not changed.”

But the powertrain of combustion alone will not be the value-creating business of the future. Which is why a primary objective of Vitesco is to develop electrification technologies across the board, from 48-volt systems to full battery-electric vehicles (BEVs). (It needs to be pointed out that there are two other business units within the company that are focused on more traditional powertrain developments, such as ECUs for direct injection systems, tank domain controller, control valves, sensors, etc.)

Making the Transition

Beyza Sarioglu is the head of the Vitesco Electrification Technology business unit in North America. She’s been with the organization since 2001 (which means that she was with the Conti Powertrain Division, as well), when she began her career as a senior software engineer.

Two key points:

- “We believe the future is electric.”

- “Long term, we think the battery electric vehicle will win the race. But hybrids are a nice transitional technology that will get the consumer used to plugging in.”

Beyza Sarioglu, head of Vitesco Electrification Technology: “We believe the future is electric.” (Image: Vitesco)

While she thinks that hybrids are the transitional tech from where the industry is now to where it is going—and she points out that there are studies showing that there will be a cost parity between battery electric vehicles (BEVs) and those powered by internal combustion engines (ICEs) before the decade is out—she also acknowledges that hybrids are “complex and costly.”

Simply: there are the ICE setup and the e-motor, power electronics, batteries.

And there is another factor that adds to the cost and the complexity, which is that different global markets have different approaches to electrification, so for a supplier like Vitesco, there is a challenge as regards being able to achieve the sorts of scale necessary for cost effectiveness. That is, China is going BEV in a big way. In Europe, there are both hybrids and BEVs gaining ground. And in the U.S., the focus seems to be more on mild hybrids than full systems.

Scale Matters

Given that, there is an issue of scale. That is, with different companies looking for different solutions in different parts of the world, there is little apparent volume to be achieved. Sarioglu says that what they’re doing is trying to find approaches that will allow sharing, which then goes to the point of scale.

She cites Vitesco’s third-generation power electronics, which she refers to as the “brain of electric drive system.” One of the goals is to get maximum current to where it needs to be when it needs to be there for propulsion. She says they use a double-sided sintering technology in producing the hardware which provides both improved reliability and thermal capacity.

But it allows something else, as well: Sarioglou says that they are supplying Jaguar Land Rover with the power electronics for both the Jaguar iPace—a battery electric vehicle—and the Range Rover PHEV—a plug-in hybrid. “It is exactly the same hardware,” she says, “but the software is a little different.”

At the start we began with full EVs. Like the iPace. And now we have brought it back around to the hybrid and the intersection between the two approaches.

RELATED CONTENT

-

On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.

-

On Electric Pickups, Flying Taxis, and Auto Industry Transformation

Ford goes for vertical integration, DENSO and Honeywell take to the skies, how suppliers feel about their customers, how vehicle customers feel about shopping, and insights from a software exec

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

.jpg;width=70;height=70;mode=crop)