Steel and Alphabet Soup

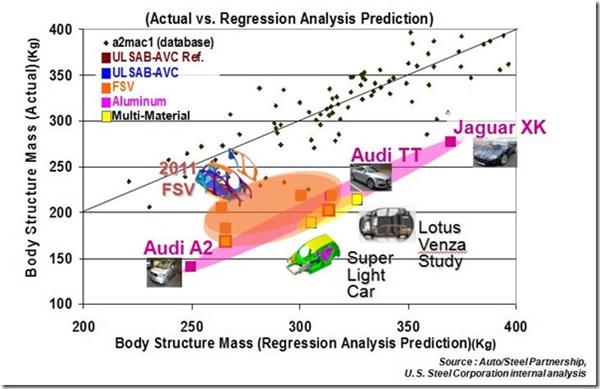

WorldAutoSteel, an organization that curiously doesn’t put spaces between the words in its name, wants designers and engineers everywhere to know that they have developed a FutureSteelVehicle design (again, leaving out spaces, apparently in a drive toward greater efficiency), and this “optimized FSV” body would tip the scales at 176.8 kg, which would make the structure’s mass comparable to aluminum structures.

#aluminum

WorldAutoSteel, an organization that curiously doesn’t put spaces between the words in its name, wants designers and engineers everywhere to know that they have developed a FutureSteelVehicle design (again, leaving out spaces, apparently in a drive toward greater efficiency), and this “optimized FSV” body would tip the scales at 176.8 kg, which would make the structure’s mass comparable to aluminum structures.

And the underlying point that they’re making is that while the structure may weigh about the same, it would be less costly than “more costly alternatives involving competing materials and multi-material designs.”

One of the areas that WAS looked at for FSV was the development of a new approach to front rails, from the standpoints of both producing the rails and providing structural safety for the vehicle. According to WAS, “The first study following announcement of the FSV in May 2011 was 3B (Draw Bead, Blank Geometry and Binder Pressure) Forming and Crash Optimization. It resulted from continuing development of the Multi-Disciplinary Optimization (MDO) Process that enabled the ‘Nature’s Way’ design used in FSV and solved the remaining forming issues presented by the FSV’s unique Front Rail structure. Through this design optimization work, the very efficient, light-weight Front Rail design is now a viable option for future production vehicles. Further, with the addition of the 3B Forming Process, the optimization software now fully comprises solutions to AHSS formability issues.”

Should there not be an uptick in the utilization of steel, it may have something to do with the fact that people may be fundamentally confused by all that FSV, 3B, MDO, Nature’s Way (since when has steel been “natural”?). . . regular designers and engineers won’t know what the heck they’re talking about.

Presumably, one might need to add a linguist to one’s product development staff.

Another aspect of the FSV is that it deploys more than 20 advanced high-strength steel (AHSS) grades—dual phase (DP), transformation-induced plasticity (TRIP), twinning-induced plasticity (TWIP), complex phase (CP), and hot formed (HF) steels—“expected to be available in the 2015-2020 technology horizon.”

“Expected”? Well, they are Talking About The Future (TATF).

RELATED CONTENT

-

Multiple Choices for Light, High-Performance Chassis

How carbon fiber is utilized is as different as the vehicles on which it is used. From full carbon tubs to partial panels to welded steel tube sandwich structures, the only limitation is imagination.

-

Cobots: 14 Things You Need to Know

What jobs do cobots do well? How is a cobot programmed? What’s the ROI? We asked these questions and more to four of the leading suppliers of cobots.

-

When Automated Production Turning is the Low-Cost Option

For the right parts, or families of parts, an automated CNC turning cell is simply the least expensive way to produce high-quality parts. Here’s why.

.jpg;width=70;height=70;mode=crop)