Coolant-targeting Toolholders; Hybrid Metal Additive-Subtractive Machine; Fastems RoboCell

Coolant-targeting Toolholders; Hybrid Metal Additive-Subtractive Machine; Fastems RoboCell

#robotics #hybrid

Coolant-targeting Toolholders

Sometimes in turning operations getting the coolant to the top of the cutting zone isn’t enough, so Seco Tools developed Jetstream Tooling Duo toolholders that can apply coolant both to the top and the bottom as needed. The toolholders feature internal channels for high-pressure coolant flow. There are two separate channels—one that directs coolant into the top of the cutting zone and another that delivers it to its underside. But if the underside cooling isn’t necessary, it can be turned off. Duo versions of the company’s MDT (multi-directional turning), X4 (grooving and parting-off) and 150.10 (parting-off) tool holders are available in 20 × 20 mm and 25 × 25 mm sizes.

secotools.com

Hybrid Metal Additive-Subtractive Machine

The SonicLayer 1200 from Fabrisonic combines its patented Ultrasonic Additive Manufacturing (UAM) process with CNC milling capabilities for complete part building and finishing. Its build envelope is 10 × 10 × 10 inches. UAM uses sound waves to join layers of metal foil—from like or unlike metals—without melting. The low temperatures and dissimilar material capabilities enable the embedding of, for example, sensors in fully dense metal parts.

fabrisonic.com

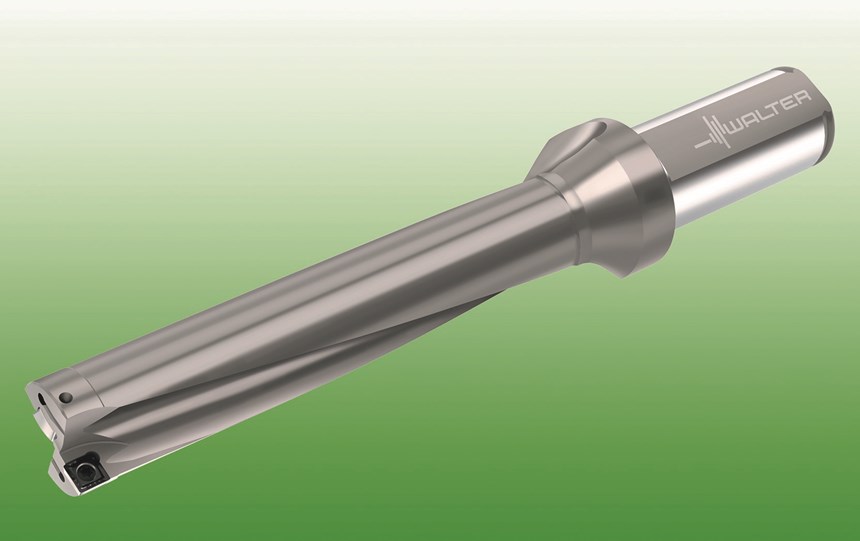

Indexable Insert Drill

The Walter D4120 indexable insert drill has hardened, polished flutes and a flute geometry designed to optimize chip evacuation. Finished surface quality and hole tolerance are improved with a wiper cutting edge on the periphery insert. A coolant-thru system—one for each of its four cutting edges—for efficient cooling and fast chip removal. The drill uses the company’s P484 inserts, which employ the company’s Tiger-tec Silver tool coating for wear-resistance and long tool life. The two-toned coating also enables edge wear to be easily observed. The drill is suitable for ISO material groups P, M, K, N,

and S.

walter-tools.com/us

Robotic Cell for Heavy Workpieces

The Fastems RoboCell One is designed to enable the simultaneous production of heavy workpieces (up to 176 lbs) in batches of different sizes on two machines of the same type (either lathes or mills). The robot operates in one linear axis to supply both machines with workpieces. The company’s manufacturing management software (MMS) automatically plans the production process, shows the current production status in real time, calculates machine capacities for outstanding orders and shows necessary machine retooling operations. The robot can be fitted with single, double or special grippers, and up to six different grippers may be used for handling workpieces in specific production operations. An optional, automated gripper change system enables the implementation of new components without interrupting production.

fastems.com

RELATED CONTENT

-

Cobots: 14 Things You Need to Know

What jobs do cobots do well? How is a cobot programmed? What’s the ROI? We asked these questions and more to four of the leading suppliers of cobots.

-

On French Concept, Inclusive Mobility, Nissan Frontier, and More

French conceptual mobility vehicles, VW addresses mobility for the disabled, a look at the 2022 Nissan Frontier, MINI surveys people about EVs, engineering the Sportster S engine, Honda’s avatar robot, and a driver shortage addressed

-

Torc Robotics Shows Snowy Self-Driving Car Test

Blacksburg, Va.-based Torc Robotics has released a video showing a prototype autonomous car navigating public streets during a spring snowstorm.