on trucks, AI-enhanced maintenance, charging, & more

‘24 Toyota Tacoma. . .Ford’s future findings. . .BMW using AI. . .standard for inductive charging. . .Callum creates an SUV. . . electrifying the trailer rather than the truck. . . using electric big rigs. . . 2024 Hyundai Kona. . .

Benchmarking for Better Building: 2024 Toyota Tacoma

“’Badass adventure machine,’ that says it all about what this new Tacoma is. There was a lot of close collaboration between engineering, planning, marketing and design. We worked together as a North American unit to make this all-new Tacoma come to life.”--Kevin Hunter, president, CALTY Design Research (Images: Toyota)

At the 22,000-sq. ft. Toyota Collaborative Benchmarking Center in southeast Michigan, teams representing Engineering, Manufacturing, Purchasing, and local suppliers get together and (a) analyze parts and components (physical and digital models) that constitute competitive vehicles and (b) work on developing parts and components for Toyota vehicles.

Like those for the forthcoming 2024 Tacoma pickup truck.

Here are some elements of the new truck:

- ISO Dynamic Seat. The objective is to keep the head stabilized particularly in off-road conditions. The seat is engineered so the cushion rotates around the inclined roll axis so the hip and torso are disconnected from the head and spine, consequently maintaining alignment. The seat provides vertical movement of 30 mm, lateral 20 mm and the upper back 19 mm; it moves in all three axes. The seat includes an air reservoir that can be adjusted with a hand pump to accommodate the driver’s weight and the type of terrain conditions.

- Exterior Lighting. There are three aspects: appearance, performance and functionality. LED headlamps are standard across all grades. Compared with the 2023 model standard halogen lamps, the LED low beam reach and width are increased 22% and 73%, respectively. Power consumption is down 58%. An LED lightbar is available that’s located in the grille below the brand badge; it provides lighting assistance under all conditions and nearly doubles the coverage of high beams alone. In the back there are LED backup lamps, LED bed lighting and LED scene lighting (these are positioned in the deck rails and provide illumination around the truck). Lighting for the Tacoma serves the primary function of plenty of illumination and the secondary one of styling.

- Hybrid Powertrain. There are three powertrains available for the ’24 Tacoma, including the iForceMAX, a hybrid. But what’s notable is that this is an instance where “hybrid” means “performance,” as this is the most powerful propulsion unit ever available on a Tacoma—even though it uses a 2.4-liter four, it produces considerably more torque than the 3.5-liter V6 available in the last-gen Tacoma: 465 lb-ft vs. 265 lb-ft. And there is a non-trivial boost in horsepower: 326 hp vs. 278 hp. The iForceMAX features a 48-hp motor in-line with an eight-speed automatic transmission. There is a 240-cell, 1.87-kWh NiMH battery (yes, nickel-metal hydride—tech that Toyota has had proven positive experience with in several generations of Prius models).

Big Numbers

One thing to know about Tacoma and the midsize pickup market: It dominates.

Through the third quarter of 2023, the U.S. sales of vehicles in the category looks like this:

- Tacoma: 179,681

- Chevy Colorado: 58,685

- Ford Ranger: 31,503

- GMC Canyon: 19,351

- Nissan Frontier: 45,895*

Given that the 2024 Tacoma was specifically designed and engineered for the U.S. market and given that it is available in eight grades (SR, SR5, TRD PreRunner, TRD Sport, TRD Off-Road, Limited, TRD Pro, and Trailhunter), odds are there will be a lot of people finding the model for them, which should keep the Taco at the top.

*It is notable that Nissan is in a solid third position when it comes to sales. For some reason the brand doesn’t get the attention that it deserves as it outsold the Ford Ranger by 14,392 units and the GMC Canyon by 26,544, non-trivial deltas in both cases.

///

Money Can’t Buy Me Love

Wanting to have a better understanding of what consumers think about their lives, Ford has been producing the “Looking Further with Ford Trends Report” since 2013. It isn’t about selling pickup trucks. Rather, it is to get a read on how people think about things that impact their lives. (Of course, the findings can be cleverly extrapolated into whether they might be interested in pickups.)

And some of the results of the survey taken in 16 countries among >16,000 people in August and September are more than a bit surprising.

As in:

In the next 10 years, my ideal living / family situation looks like…

- Having children: 26%

- Having pets: 34%

(Maybe three-row SUVs will not be all that important in the next 10 years: dog cages, yes.)

But one finding probably caused considerable pause among the Ford C-suite.

As in:

To achieve a lifestyle that prioritizes my quality of life, I would be willing to take a 20% pay cut.

- 52% of those employed agree

Now, that 52% is a global average, ranging from a high in Thailand (69%) to a low in Mexico (40%).

The U.S.?

- 51%

That’s right, more than half of American workers would be willing to have their salaries reduced for purposes of lifestyle.

Wonder if Shawn Fain knew?

(Note: This finding may be of use to the non-Traditional Three the UAW will work to organize: focus on making sure that workers recognize there’s quality of life on offer.)

///

AI Comes to Predictive Maintenance at BMW

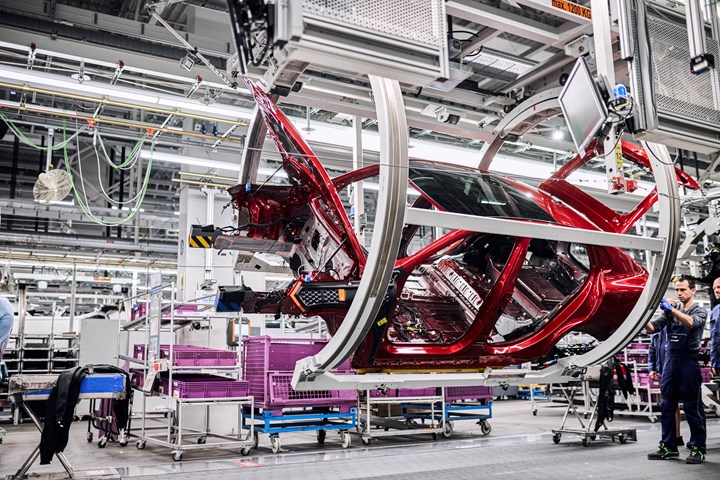

AI helps the BMW production line producing the iX2 running with minimal downtime. (Image: BMW)

Back in the days when “lean production” was a topic*, the term “preventative maintenance” came up every now and then (fixing stuff, apparently, isn’t as engaging as making stuff).

However, if a machine unexpectedly goes down, that results in “no production,” lean or obese.

Preventative maintenance gave way to “predictive maintenance.”

Predictive maintenance uses everything from sensor data collected from the equipment to historical downtime to figure out when something needs to be attended to—before it needs attention.

At the BMW plant in Regensburg, Germany, they are taking this one step farther by performing “smart maintenance.”

That’s essentially predictive maintenance taken to another level through the use of artificial intelligence.

Non-trivial Benefit

What does this get them?

“We are currently avoiding at least 500 minutes of downtime per year in vehicle assembly alone,” said project manager Oliver Mrasek.

While 500 minutes over the course of a year may not seem like a big deal, it is.

The production rate at the plant is one vehicle per 57 seconds, so that’s about 525 BMW iX2s that aren’t lost to downtime.

BMW is currently using the AI-supported system at Regensburg to monitor its vehicle conveyor systems.

As it had a predictive maintenance system in place, there was no need to add any sensors or hardware for the AI system.

Mrasek: “The only costs are for storage and computing power.”

Hard not to do it.

*”Lean production” was synonymous with the “Toyota Production System” (TPS) which some people argue is passé in light of the advances being made in manufacturing by Tesla, such as gigacastings and a process combining serial and parallel assembly for the next-gen Tesla, the “unboxed process” that is claimed to reduce the manufacturing footprint by >40% and reduce cost by 50%. Those numbers are remarkable if achievable. However, I’d argue that TPS is as relevant to consumers today as it ever was. It is widely known anecdotally that Tesla owners give their vehicles a pass on build issues that would be unacceptable for other brands. According to the J.D. Power 2023 U.S. Vehicle Dependability Study—which looks at how model year 2020 vehicles have held up in terms of quality, component replacement and appeal—based on a metric of problems per 100 vehicles (PP 100), Lexus is the top brand with a score of 133 PP 100 and Toyota is in seventh place, with 168. Tesla? 242 PP 100. According to S&P Global Mobility, the average age of cars and light trucks on the road now is 12.5 years. Which means that dependability is important. And TPS certainly contributes to making vehicles that are dependable.

///

Plugless Charging Positioning Standard

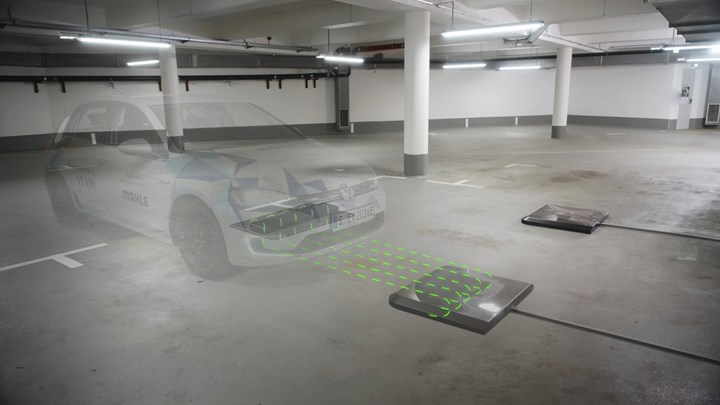

New standard helps with the orientation of an EV and an inductive charge pad. (Image: MAHLE)

Thirty-six percent of Americans surveyed last year acknowledged their garages are so cluttered that they can’t park their vehicles inside them.

What’s more, 62% who took part in the survey conducted by CRAFTSMAN brand, which makes among other things tools that can be used to fix cars, said their garage is the most cluttered place in their home.

Which may make the deployment of the MAHLE Differential Inductive Positioning System (DIPS) less widespread than it might be.

The what?

MAHLE, a company that focuses on electric drives and charging, vehicle thermal management, and internal combustion engine tech (“we will remain a reliable partner to our customers around the world as long as demand exists” for ICEs), has developed a system that allows electric vehicles with inductive charging capability to be precisely positioned over the charging coil on (or in) the floor.

Say in one’s garage. No plugs required.

DIPS has been selected by SAE International as a global standard for the application.

The driver simply follows directions provided by a special navigation system screen for the positioning. (And were one to have an autonomous parking-capable vehicle, it works with that, too.)

Of course, this requires a vehicle be capable of inductive charging.

(Briefly: there is a magnetic coil in the charger on the floor that communicates with a receiver installed in the vehicle, which also has a coil: when the two are aligned, the charging begins: No plugging in required. But the vehicle requires that capability.

(One snag: there is no EV you can buy that comes with inductive charging capability standard. According to the folks that organize the EV Charging Summit, “only one EV sold in America has wireless charging as a factory option – the BMW 530e hybrid sedan.”)

Which brings us back to the garage.

Don’t most people simply use a tennis ball hanging on a string from the ceiling to properly position their vehicles?

///

Callum Knows Function, Too

One thinks that there probably aren’t a whole lot of learnings that Ian Callum took away from his stint heading Jaguar design for this, his Skye. (Image: CALLUM)

Although legendary designer Ian Callum is associated with vehicles including the Aston Martin DB7 and the Jaguar XF, it is worth noting that his first job in the industry was at the Ford Dutton Technical Center in the U.K. where, among other things, he designed things like the side mirrors for the Ford Transit Van.

Or said another way, Callum isn’t all posh.

So it isn’t entirely surprising that although it is certainly upscale, there is functionality as part of the first branded vehicle from the eponymous design consultancy he heads: the CALLUM SKYE.

It’s a multi-terrain electric vehicle.

Callum:

“At four metres long, the CALLUM SKYE is dramatically proportioned with a concise exterior aesthetic driven by its capabilities. It has been designed to exceed expectations: minimal mass, maximum capability--exceptionally usable and an absolute joy to drive.

“The exterior features a striking accent loop, intersected by a strong horizontal structure, flanked by organic forms front and rear. It is pared down to a level of necessity and understatement.”

Said like the designer he is.

From a more operational point of view, there’s this from Adam Donfrancesco, CALLUM head of Engineering:

“We set an uncompromisingly high bar with our functional targets for the CALLUM SKYE, creating a compelling, unique, versatile and durable vehicle. Throughout the development journey, we have held steadfast to the principals of simplicity and integrity, ensuring the CALLUM SKYE conquers the rigorous demands of a variety of off-road terrains, while still delivering the ride comfort and handling that transforms winding country roads into captivating experiences for both the driver and passengers.”

Specifics about the vehicle (beyond such things as a 42-kWh battery, a weight of 1,150 kg, an anticipated range of 170 miles, and a <4-second 0 to 60 time) will be released in spring 2024.

///

Electrifying the Trailer

BMW is testing electric trailers for transport. Provides an emissions advantage especially when the tractors are powered by diesel. (Image: BMW)

BMW Group Logistik recently performed an interesting test—in real logistics operations—in which it deployed an electric semi-trailer.

That’s right: the trailer is electric, not the tractor.

The trailer was developed by Trailer Dynamics GmbH.

Operating around the BMW plant in Dingolfing and running between Mamming and Leipzig, Germany, it was determined that if a diesel truck was used with the electric trailer there was an average fuel savings of >46% in the short- and medium-distance runs and >48% in the long run.

Then they did the same combining the trailer with an electric tractor and were able to achieve a range of >600 km (>373 miles).

Elements of the Trailer

The trailer is fitted with 400/600 kWh lithium-iron-phosphate battery modules, an electric axle up to 580 kW, and a control unit that coordinates the e-axle with the tractor’s powertrain.

Although using batteries in the trailer means additional mass, which means that (a) the amount of cargo is reduced and (b) there is the need to use extra energy to move it, it was determined that there is a beneficial reduction in carbon emissions.

“As the BMW Group, we are—as the first German car manufacturer—a member of the ‘Business Ambition for 1.5°C’ of the Science-Based Targets Initiative and are committed to the target of complete climate neutrality throughout the entire value chain. Therefore, we are using visionary projects to consistently accelerate the BMW Group’s Green Transport Logistics strategy. The pilot testing with Trailer Dynamics’ e-trailer showed that using this kind of electrified semi-trailer significantly reduce the fuel consumption of standard diesel tractors and noticeably increases the range of e-trucks.”—Michael Nikolaides, Head of BMW Group Production Network and Logistics

As for the potential for reduced cargo because of the batteries, while there are regulations regarding the amount of weight that a trailer can carry and while 16 tons of battery modules can take a non-trivial amount of available capacity, according to a BMW spokesperson:

“This payload reduction would only be relevant for weighed-out transport, which play a minor role for BMW Group Inbound logistics.”

Why?

“Most transports are cubed out.”

In other words, it is a matter of package size more than package mass.

Given that there are a whole lot of diesel tractors out there, the utilization of electric trailers can certainly help logistics companies reduce their emissions while keeping their diesels.

Not ideal to continue burning diesel. But given the number of tractors with diesels out there, a practical solution.

///

Cleaner Commercial Vehicles

Schneider operates its EV trucks out of its Southern California Intermodal Operations Center, where it has constructed a charging depot with 16 350-kW dual-corded chargers. The trucks can get to an 80% charge in about 90 minutes and have a range of up to 220 miles. (Image: Schneider)

Speaking of trucks. . .

Although there is plenty of focus on electric light-duty trucks, big rigs do have promise for emissions reduction.

According to a recent report in Electrek there have been approximately 70 Tesla Semis built. . .which makes it all the more impressive that Schneider National, a hauling and logistics firm, has a fleet of 94 electric trucks: 92 Freightliner eCascadias and two electric yard spotters.

Schneider worked with Daimler Truck North America (DTNA) on the development of the eCascadia, including piloting a vehicle in service for six months in 2020-2021.

Its fleet—running goods for companies including Goodyear and Frito-Lay North America—has now racked up more than 1-million zero-emissions miles in service.

The company calculates the eCascadias have avoided about 3.3-million pounds of carbon dioxide emissions. That’s equivalent to what some 330 gasoline-powered cars emit annually.

From California to London. . .

An electric black cab in London. (Image: LEVC)

Still in the commercial vehicle space. . .

Meanwhile, the London Electric Vehicle Company (LEVC), which produces black cabs that are EVs, has calculated that since the vehicles were introduced in 2018, the >10,000 cabs (more than 7,500 of which are in London, which means that more than half of the black cabs in London are electric) have prevented more than 220,460 tons of carbon dioxide emissions during the total of >700 million miles traveled.

To help provide a visual of what 220,460 tons represent, LEVC says that it is equal to more than 110,000 passenger flights from London to Sydney.

///

2024 Hyundai Kona Limited

The ‘24 Kona is available with ICEs under its hood—though it was originally designed to accommodate an electric propulsion system. (Images: Hyundai)

Sometimes the front and rear of vehicles appear to have been designed by two people who have never met, have nothing in common and appear to have been working from entirely different briefs.

If there is anything from a design perspective that I give the all-new 2024 Kona full marks for it is the symmetry of the front and rear designs.

There are what are called “horizon lamps” on each, with the lightbar in the front positioned so that the hood seam is essentially invisible, and with the rear pixelated lamp a few inches below the backlight.

This Kona was designed first to be an EV and then an ICE, and so the term “futuristic” is absolutely apt for what they’ve achieved with the styling of the vehicle.

The bodysides, however, leave me somewhat less than enchanted. There are large swaths of cladding on the front and rear quarters and along the sill. That and the use of a Z-shaped character line running from the top of the front quarter across to the rear door handle, then diving down to a spot just above the sill cladding near the bottom of the front door, then back, ending at the cladding on the rear door is a bit fussy. If the front and rear evoke a sensibility about the future it is one of spacecraft. And what the side signifies is, perhaps, some sort of all-terrain vehicle designed to clamber over geologic formations on Mars. Rocket vs. rock-crawler.

Full disclosure: I really like the design of the first-generation Hyundai Kona, which was introduced as a MY 2018 subcompact crossover SUV.

That said, although I am not as taken with the styling of the all-new MY 2024 Kona, (1) it certainly is time for a change and (2) I suspect that Hyundai figures it has the Venue, Tucson, Santa Fe, and Palisade, all of which have more conventional SUV styling, so this allows them to appeal to a different segment.

Sizeable

A big change is that the second-gen Kona is. . .bigger.

Specifically:

- Length: 171.3 inches, up 5.7 inches

- Width: 71.9 inches, a 1-inch increase

- Height: 63.6 inches, an additional 2.6 inches

- Wheelbase: 104.7 inches, 2.3 inches added

The place where this is really notable, valuable and useful is on the inside.

Passenger volume has gone from 94.1 cubic feet to 101.2 cubic feet.

Cargo volume was 19.2 cubic feet and now it is 25.5 cubic feet (which Hyundai says can accommodate two golf bags and four duffels or three 28-inch suitcases).

Under the hood there are two choices: a base 147-hp 2.0-liter engine mated to a CVT or a 190-hp 1.6-liter turbo mated to an eight-speed automatic.

Affordable

The vehicle really has a remarkable amount of standard safety tech on board, including forward collision-avoidance assist, blind-spot warning, rear cross-traffic collision avoidance assist, lane-keeping assist, lane-following assist, high-beam assist, safe-exit warning, driver attention warning, and rear occupant alert. Realize that all these are standard and there is an abundant number of options that one might imagine would be available only on higher-end vehicles.

What’s more (or less): the starting MSRP for a front-drive Kona with the 2.0-liter engine is $24,100. The the top-of-the-line Kona Limited with all-wheel drive and a 1.6-liter turbo is $33,150.

There are more aspects of the Kona that can be characterized as “striking” than one would expect in its category, whether it is content or capability.

Styling, of course, is a matter of taste.

RELATED CONTENT

-

Frito-Lay, Transportation and the Environment

Addressing greenhouse gas reduction in the snack food supply chain

-

On Ford Maverick, Toyota Tundra Hybrid, and GM's Factory Footprint

GM is transforming its approach to the auto market—and its factories. Ford builds a small truck for the urban market. Toyota builds a full-size pickup and uses a hybrid instead of a diesel. And Faurecia thinks that hydrogen is where the industry is going.

-

Aluminum Sheet for EV Battery Enclosure

As the number of electric vehicles (EVs) is about to increase almost exponentially, aluminum supplier Novelis is preparing to provide customers with protective solutions

.jpg;width=70;height=70;mode=crop)