on Pininfarina's Adventures in Aero, Developing the Cadillac LYRIQ, AlixPartners on EVs, & Schaeffler's Sustainability Approach

Pininfarina made some slippery cars and then got a wind tunnel. . .the Cadillac LYRIQ team developed a crossover that sets a new standard for the brand. . .AlixPartners explains the ICE-EV transition is tricky for suppliers. . .Schaeffler uses the power of people. . .

Aero in Italy

The wind tunnel and the electric hypercar Automobili Pininfarina Battista. (Image: Pininfarina)

“Going to the mountains in winter I saw how the wind had streamlined the snow at the side of the road, carving out curved or sharp shapes at the edges. The wind event gives shape to trees. I wanted to copy those lines…”--Battista Pinin Farina

Since its establishment in 1930, Pininfarina styled cars notable for their aerodynamics.

By 1965 the company started studies for the potential of building a full-scale wind tunnel for vehicle development. In 1970 Sergio Pininfarina green lighted the project.

In 1972 the wind tunnel in Grugliasco was opened.

At the time, according to the company, it was one of seven in the world capable of testing full-size cars. It was the first in Italty.

And now it’s in its 50th anniversary year.

Specs

- The test section of the unit has a plenum length of 13.3 m, a jet length of 8 m, a width of 9.6 m and a height of 4.2 m.

- There is a 1.1-mW DC motor to drive the main fan.

- The fan diameter is 4.88 m. It has 29 blades.

- There are 13 other smaller fans (1.8 m diameter; 13 blades each).

- The maximum wind speed is 70 m/s, or 250 km/h.

The test system includes a ground effect simulation system that puts rotation in the wheels and simulates the motion of the ground under the car and a turbulence generation system to simulate actual conditions on a road.

In addition to cars, the Pininfarina wind tunnel has been used to measure trains, trucks, aircraft, yachts, golf clubs, motorcycles and ski boots.

The Pininfarina wind tunnel was also used to design and develop the torch for the 2006 Turin Winter Olympic Games.

(Italy came in 9th in the medal count with five gold and six bronze medals.)

///

2023 Cadillac LYRIQ: The Commitment

The 2023 Cadillac LYRIQ. (Image: GM)

One of the things you learn when talking to the people—designers, engineers—who worked on the Cadillac LYRIQ is that they were deeply committed to the program in a way that probably exceeded that of other vehicles they’ve worked on during their careers.

This is not to underplay any previous commitment.

But it does seem as though with the LYRIQ they knew they were involved in the creation of not only an all-new electric vehicle, but a vehicle that arguably has more impact on the future viability of Cadillac’s continued existence than any other vehicle in its recent history.

- Subsequent new Cadillacs will be EVs. Should the LYRIQ not create traction for the brand, then that plan has problems.

- It could be plausibly stated that were it not for the success of the Escalade—launched in model year 1999, now in its fifth generation—Cadillac’s present existence would likely be questionable. The LYRIQ is important like that.

One of the phrases you hear when various aspects are being described—whether it is the Ultium battery cell module assemblies (24 cells per module; 12 modules for the 102-kWh battery pack, which provides the vehicle with 312 miles of range in the RWD configuration), the five-link suspension setup (the first Cadillac SUV to have one) or the three-axis accelerometers on each corner of the vehicle for the active noise-cancellation system or a multitude of other features—is “redefining Cadillac.”

They are all in on that.

==

LYRIQ: Yes, the front end

Yes, a light show in the front. (Image: GM)

Let’s get one thing out of the way.

The thing that Tristan Murphy, interior design lead, says is exceedingly important to the crossover:

The front end.

The light show.

They start with a sheet of polycarbonate. The back is painted black. A laser is used to ablate the specific pattern on the surface. Then a coat of white is applied. That provides the impressive illumination in the space that would otherwise be considered the grille.

(This also allows future models or trims to have a different look, as the laser could be programmed to ablate different sections.)

Murphy explains that he fully recognizes exterior design matters so as to get people into the vehicle. Then they can see the work he and his colleagues have executed.

Incidentally: There is a laser-enabled light show that occurs on the inside of the LYRIQ, too. . . .

==

LYRIQ: Lights on the inside

The small triangles are laser-cut in the wood. The backing is a thin sheet of metal that actually allows light to shine through at night. (Image: GM)

Murphy says that the black ash door trim has small triangles cut out of its surface with a laser.

Behind that section there is a 0.25-mm thick sheet of metal veneer. He says it is so thin that it is translucent.

“During the day, you can see the wood-over-metal appearance. At night, the ambient light color shines through the metal,” Murphy explains, adding, “We are the first ones in the industry to be doing anything like this.”

There is another section of metal on the interior (beyond the PVD-coated pieces that are copper or chrome used to finish-off individual elements, exhibiting a keen eye for the details) that is notable: The speaker grille on the front doors.

According to Murphy, the supplier for the parts started working on the design which requires blanks “almost the size of the door” and found that unlike what they oridinarily did, the draws were too deep and the geometry too complex.

So GM brought in exterior sheet metal experts—the people who are usually dealing with body panels—to help the supplier achieve the competency required for stamping the speaker grilles.

(The LYRIQ has a 19-speaker audio system from AKG Studio.)

==

LYRIQ: And the display

The screen stretches across the IP. While it is showing a start-up animation here, it provides a vast array of information and actuation. OTA updates will make it even more capable going forward. (Image: GM)

OK. One might maintain that there is still another light show of sorts in the LYRIQ:

The 33-inch diagonal LED display.

Sandy Lipscomb, Software Defined Vehicle User Interface Senior Manager at GM, explains that this screen not only has remarkable resolution, but it provides the ability for the driver not only to access the information that may be wanted for a given drive (e.g., state of battery, navigation, audio settings) but will, through over-the-air updates, “change over time.”

There will be the availability of new themes and capabilities.

Lipscomb explains that they are thinking in the context of what expectations are by people who interact with their smart phones on a regular basis: the hardware may stay the same (of course, not even Apple has something with a starting MSRP of $58,795, and that is for the Debut Edition of the LYRIQ, which is sold out, so one is likely to keep their vehicle longer than their phone), but the available content—as well as the look of the screen—will change over time.

Lipscomb says this is simply what customers of today expect.

Tristan Murphy emphasizes that the screen—unlike those offered by other OEMs—truly is a single screen, not a single sheet of curved glass with multiple flat screens behind it.

Although there are functions that can be controlled through the screen (“soft controls”) there are also switches, buttons and knobs (“hard controls”) that Murphy says are all designed for Cadillac: this isn’t an accumulation of things picked out of the GM parts bin.

==

LYRIQ: Steel & stiffness

The LYRIQ is manufactured at the GM Spring Hill Assembly Plant in Tennessee. (Image: GM)

The body-in-white and battery pack structure consist of a variety of steels, including:

- Mild steel

- High-strength steels (BH, P, HSLA)

- Advanced high-strength steels (DP, LCE)

- Ultra high-strength steels (MS, MP, CP)

- Press hardened steels

All closure panels are steel.

Rob Kotarak, vehicle chief engineer: “We did a lot of material optimization for the vehicle. We put the right steel in the right place.”

One of the aspects of the vehicle’s structure is the battery pack, which also contributes to the low center of gravity for the vehicle as well as good weight distribution, whether this is for the RWD version, which produces 340 hp with the one motor, or the AWD version, which produces 500 hp with two motors.

Kotarak says that the torsional stiffness of the LYRIQ is 31.5 kN/m°, which puts the crossover in luxury sedan space.

The LYRIQ is being produced at the GM Spring Hill Assembly Plant in Tennessee (where the Cadillac XT5 and XT6 and GMC Acadia are also being built).

GM invested $2-billion in the plant to make it capable of building the LYRIQ.

==

LYRIQ: There’s always 2024

You can’t always get what you want. For now. The 2023 Cadillac LYRIQ is sold out. (Image: GM)

The 2023 LYRIQ is sold out. There is a wait list to pre-order a model year 2024 vehicle: initial deliveries for that are expected to occur in spring 2023.

Kristen Lewis, LYRIQ marketing manager, says that not only has the demand been notable, but the people who are interested in the crossover are:

- New to Cadillac—about 78% of them

- Younger—about two thirds from Gen X and Gen Y

- Wealthier—higher household incomes than usual

- More well educated

- Geographically ideal—over-indexing in the Western region (e.g., California)

One thing that is interesting when you talk with these people who are on the LYRIQ program: they are completely aware of Tesla and the other competitors.

But they evince a non-braggadocious confidence that what they are doing is going to put Cadillac in a good place.

==

LYRIQ: Tribute

LYRIQ sill: a nod to the company’s past. (Image: GSV)

Back in the proverbial day, the door sills of Cadillacs featured the brand logo and an image of a horseless carriage with the line: “Body by Fisher.”

Murphy says that to acknowledge that in a subtle way, they added an illustration of the LYRIQ to the sill of the crossover.

==

LYRIQ: Tribute 2

The Cadillac merlettes: a “deep track.” (Image: GSV)

The original Cadillac badge was a nod to the family crest of Antoine de la Mothe Cadillac, who is credited with founding Detroit in 1701. Henry Leland and William Murphy, who founded Cadillac in 1902, decided to give some credit to the French adventurer.

That crest included birds, merlettes, not ducks, as is commonly thought.

The merlettes have been used on and off on the Cadillac logo since.

Presently off.

However, on the sides of the LYRIQ instrument panel the little birds make a return.

A nice touch that Tristan Murphy doesn’t refer to as an “Easter egg” but, rather, a “deep track.”

They clearly put a whole lot of depth in the thinking behind the development and execution of the LYRIQ.

///

Being a Supplier Has Always Been Hard. And Now Harder

Suppliers are unlikely to catch a break anytime soon. And those suppliers strongly linked to internal combustion engines are likely to break—either into a “new co” and “old co” or simply be broken—as the inexorable shift to electric vehicles gains traction according to analysis from AlixPartners.

And here’s something to keep in mind about this: Elmar Kades, AlixPartners Global Co-leader, Automotive and Industrial Practice, says there is likely to be an inflection point for internal combustion engines starting in 2024.

This means from that year on there will be a decrease in the demand for (and production of) ICEs:

Between 2024 and 2028 there will be a 33% drop in Europe, and while there will be a decline during the same period of 12% in North America, that is (a) a movement in the wrong direction for ICE-associated suppliers and (b) a decline that will only continue.

Kades says that they project that EVs will have a 28% market share in North America by 2028 (globally: 33%).

There is no turning back. Especially as Kades’ colleague, Mark Wakefield, also Global Co-leader in the space, points out they reckon that investments by global OEMs in EVs will be “well above $500 billion” over the next five years. As in $526 billion.

Financial cringe

The OEMs have been doing well financially of late, as vehicle pricing has been, as AlixPartners puts it, “extremely robust.”

Things are not working as well for suppliers for various reasons, including:

- Frequent shifts in schedules, resulting in production inefficiencies

- Rising raw material costs

- Rising freight costs

Wakefield says that OEMs have been able to pay down their debt. Suppliers haven’t.

Profits are a problem for suppliers.

And for some, things are going to get much worse.

Insourcing issue

Kades: “Insourcing by OEMs is a threat to suppliers.”

AlixPartners has broken down an electric powertrain and calculated that of the total components, traditional suppliers can get about 28%.

These areas include the battery pack, the battery management system, e-drive inverters, onboard charger, DC-DC converters, and a very small bit of e-motors.

The rest will be done by the OEMs, joint ventures with OEMs or new entrants.

At the same time, they calculate that the part costs for a battery electric vehicle will have an overall net growth of approximately $9,000 in content per vehicle while ICE-related components will decrease by about $5,000.

Simply: those who make EV-related parts will have more business; those who make ICE-related parts will have less.

Approaches

So what’s a supplier to do?

AlixPartners found that in its survey of suppliers, a group that it characterizes as “Early Adopter,” representing 37% of the total, are in the process of transforming operations from ICEs to BEV—and of that group, 25% are winding down their ICE activities and 22% are selling or spinning them off.

It is notable that of the three groups—Early Adopter, Joiner (i.e., making the transition within five years), Follower (no immediate plans)—the plan to continue with no major investments (remember the previously mentioned ICE inflection point?) is non-trivial:

- 44% Early Adopter

- 48% Joiner

- 68% Follower

Or, on average, 53% aren’t going to be adding to their ICE production capacity regardless of whatever else they do or don’t do.

The consequences are not going to be borne by the supply base alone, however. Kades points out there needs to be a managed transition from ICEs to BEVs for OEMs and suppliers to avoid things like supplier bankruptcies, continuity costs (i.e., costs keeping suppliers afloat) and validation and tooling costs.

Unless that transition is managed, AlixPartners calculates it could cost as much as $70 billion by 2030. Managed appropriately, that figure is reduced by 40 to 60%.

Bottom line

Traditional suppliers dependent on ICEs are simply going to find their business in that area is going to decline sooner rather than later and so they had better start finding ways not only to bolster that business (e.g., consolidation) but to find alternatives to it.

///

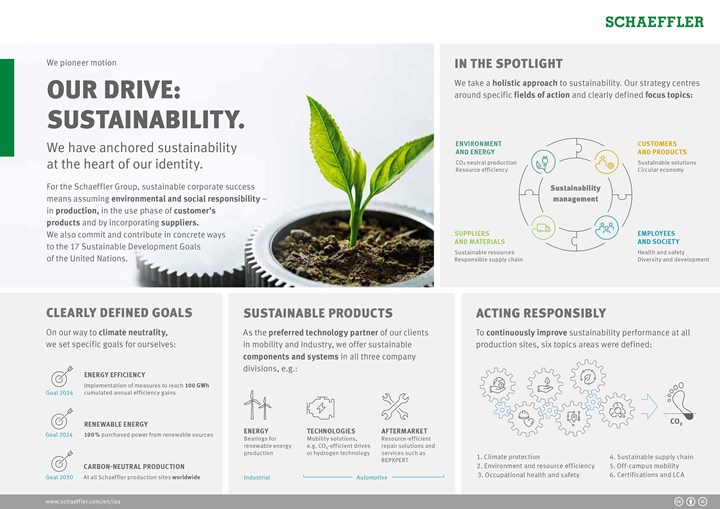

Green Ideas Rooted in People

A global effort to get better involves all of its associates. (Image: Schaeffler.)

“Global Climate Action Day” was held last week at Schaeffler Group facilities around the world.

The company’s ~83,000 employees spent 90 minutes on June 22 participating in some 4,000 workshops—both physical and virtual—focusing on addressing CO2 emissions reductions:

- Green materials

- Green production

- Green products

Schaeffler is signed on to the Paris Climate Agreement. It plans to be carbon neutral by 2040—and this goes beyond the company itself—and it plans to have its production operations carbon neutral by 2030—to its entire supply chain. Which explains the 10 years between 2030 and 2040.

Here’s the thing:

During the Global Climate Action Day the company obtained >20,000 ideas from its employees.

Ideas ranging from materials to energy sources to transportation alternatives.

20,000 ideas from the people of Schaeffler. Ideas that can beneficially impact the company—and the environment.

83,000 people who recognize that the company takes them—and the environment—seriously.

“The company is now further developing and reviewing these ideas.”

Ideas are a renewable resource.

How many companies, unlike Schaeffler, are wasting it?

RELATED CONTENT

-

On The Jeep Grand Cherokee, 2022 Nissan Pathfinder, and More

An inside look at the Detroit Assembly Complex-Mack; a innovative approach to waste-free, two-tone painting; why a forging press is like an F1 car; and other automotive developments.

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

-

On Ford Maverick, Toyota Tundra Hybrid, and GM's Factory Footprint

GM is transforming its approach to the auto market—and its factories. Ford builds a small truck for the urban market. Toyota builds a full-size pickup and uses a hybrid instead of a diesel. And Faurecia thinks that hydrogen is where the industry is going.

.jpg;width=70;height=70;mode=crop)