on Hydrogen, Micromobility, Mining EV Minerals, AV Delivery Bots & More

More-efficient fuel cell. . .Kenworth/Toyota hydrogen big rigs. . .appropriate e-scooter parking. . .robots in China. . .mining for EV minerals. . .Hyundai Palisade. . .Magna building delivery AVs. . .a fashionable French color

Hydrogen > Diesel

Fuel cell with improved efficiency for commercial applications. (Image: Loop Energy)

Commercial truck operators have plenty of considerations, especially diesel fuel costs.

The folks at Loop Energy, a designer and producer of hydrogen fuel cells for commercial applications, have developed a 120-kW system, the S1200, that they say has a fuel-to-wheel efficiency more than double that of a diesel engine-powered vehicle.

That is, the S1200 is designed to provide up to 60% in net system efficiency.

Installed in a vehicle, this means that the fuel-to-wheel efficiency can be up to 54%.

A comparable diesel setup provides 20 to 25%.

Loop Energy engineers have addressed fuel efficiency and power output.

Changes

So to that end it did two things. One is increase the size of the bipolar plates compared with the company’s previous-generation fuel cell.

The other is changing the plate shape from rectangular to trapezoidal. This helps provide a uniform current consistency across the active area of the plates and increases gas velocity (remember: H2 and O2 go into a fuel cell), which improves performance and water management (also remember: the “emissions” of a fuel cell consists of water).

Costs

A Deloitte study on fuel costs predicted that there would be diesel-hydrogen cost parity by 2030.

Loop Energy President & CEO, Ben Nyland:

“The S1200 brings world-leading fuel efficiency levels for medium to heavy-duty vehicles, crucially making the total cost of ownership lower and bringing fuel cost parity forward by four-to-eight years.”

This is not a proof-of-concept. It is ready for order. The plan is that vehicle manufacturers will source the fuel cell system from Loop Energy and then integrate it into their own platforms.

The S1200 is configured primarily for new electric platforms, not retrofits.

>>>

Fuel Cells at Work

Fuel cell electric vehicle (FCEV) used in commercial operations, such as hauling Toyotas to dealerships. (Image:Toyota)

While on the subject of fuel cells for commercial vehicles. . .

Toyota North America and Kenworth Truck Company have been operating 10 Class 8 fuel cell-powered trucks at the Port of Los Angeles, in the Los Angeles basin and in the Inland Empire doing real work hauling various types of cargo.

The Class 8 T680 trucks have been part of the Zero- and Near-Zero Emission Freight Facilities (ZANZEFF) “Shore-to-Shore” project.

Kenworth built the trucks. Toyota built the fuel cell electric power system.

An objective was to benchmark the performance of the fuel cell electric vehicles (FCEVs) compared with diesel rigs in drayage and other short-run operations.

Why?

Surprising stat: Although the number of medium- and heavy-duty trucks of the sort that are operating at the Port of Los Angeles make up only some 3% of the total vehicles on the roads of California, they are responsible for about 23% of the vehicular greenhouse gas emissions.

Mission Achieved

The trucks in the program each reduced CO2 emissions by 74.66 metric tons compared to the baseline diesel engine.

Almost There

In announcing the end of the program Toyota acknowledged that the goal had been to “nearly match the performance of diesel-powered drayage trucks while eliminating emissions.”

That “nearly” puzzled us. So we asked Toyota to clarify:

“The baseline when this project first started was around 2017 so a diesel powertrain of that era was the comparison. We say 'nearly' here because spec for spec there are some minor differences. For example, we exceeded performance by having a range of 300+ miles on a single fill, and comparing to what a typical 200-mile drayage route a diesel-powered truck would run means we meet that need; however, when it comes to fill time, even at 15-20 minutes for hydrogen, diesel can still be done a little faster. With some further improvements, we believe it can match that fill time, hence the 'nearly' for now.”

Infrastructure

It’s always infrastructure.

But Shell participated in the program—it built three hydrogen refueling stations.

Wayne Leighty, Shell Hydrogen Mobility, Commercial Head, North America:

“Shell anticipates a great use-case for hydrogen in Commercial Road Transport here in California and the success of the ZANZEFF project has been an important step in achieving commercialization.”

Projects are nice. Commercialization is key.

Speaking of Which. . .

Last year Toyota announced that along with Camrys, Toyota Motor Manufacturing Kentucky is going to build dual fuel cell modules that can deliver up to 160 kW of continuous power.

When making the announcement, Tetsuo Ogawa, president and chief executive officer, Toyota Motor North America, said: “Heavy-duty truck manufacturers will be able to buy a fully integrated and validated fuel cell electric drive system, allowing them to offer their customers an emissions-free option in the Class 8 heavy-duty segment.”

Seems like the work done by Kenworth, Toyota and other ZANZEFF participants shows commercial FCEVs are a viable approach.

Timing Is Everything

And this is timely. On October 27 the California Air Resources Board (CARB) will be holding a hearing on an Advanced Clean Fleets (ACF) regulation.

According to CARB:

“The proposed ACF regulation would require certain fleets to deploy ZEVs starting in 2024 and would establish a clear end date of new medium- and heavy-duty internal combustion engine (ICE) vehicle sales in 2040.”

FCEVs and battery EVs are going to become even more important.

>>>

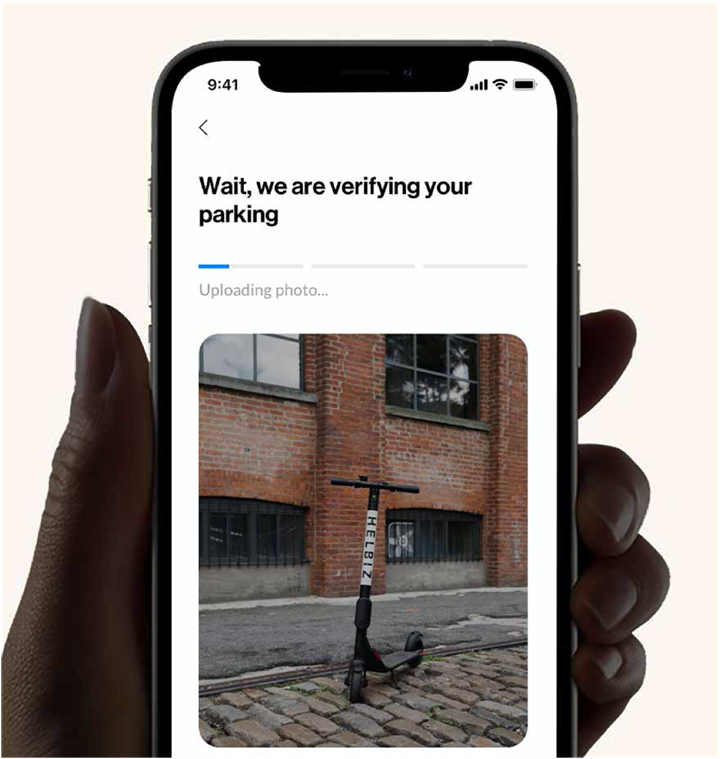

Appropriate Parking for E-Scooters

When parking a scooter the rider takes a photo, uploads it and it is quickly determined if it is parked as it should be. (Image: Helbiz)

According to the U.S. Bureau of Transportation Statistics, as of July 2022 there were 300 e-scooter systems serving 158 cities. That’s up from 215 systems and 93 cities in 2020. The e-scooter spread is much bigger than dockless bike systems (2020: 45 systems in 35 cities).

One of the issues related to the proliferation of e-scooters is that they are often randomly arrayed and abandoned on sidewalks.

Quick Verification

So Helbiz, a micromobility services supplier, has developed “ParkSense,” an AI-powered parking verification tool.

At the end of a trip, the rider is instructed to take a picture of the device with a smart phone. Then, in less than a second (95% of the time) there is a determination of a variety of things, ranging from whether the e-scooter is blocking a sidewalk or a business doorway.

The system is tailored to specific city requirements.

It doesn’t require additional hardware.

Helbiz sees ParkSense as something it can license to other micro-mobility operators and emphasizes that it doesn’t require AI expertise or a software development kit (SDK), just a few lines of code.

Arguably another example of simple tech.

And presumably it will make micro-mobility less of a non-user hazard.

>>>

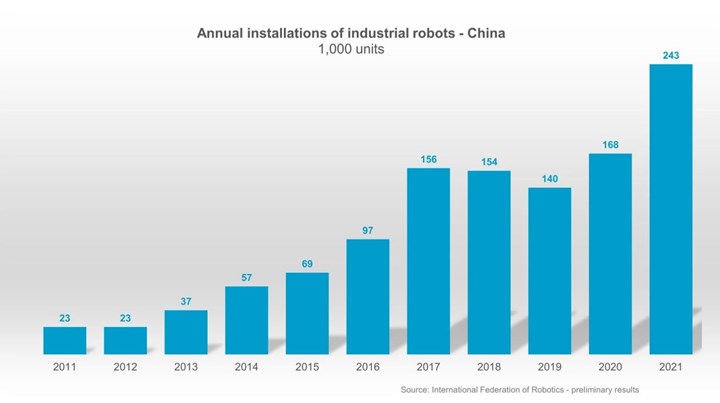

Robots in China

Who knew so many robots are being deployed in China? (Image: IFR)

You might imagine that with its vast population (1.4-billion) China wouldn’t need much in the way of automation.

Yet preliminary numbers from the International Federation of Robotics (IFR) have it that in 2021 China had a record 243,000 robot installations, a 44% increase over 2020 installations— and half of the global installations.

Marina Bill, IFR president:

“China still has high potential for further growth. The country´s robot density in the manufacturing industry amounts to 246 industrial robots per 10,000 employees thus ranking ninth worldwide in 2020.”

To put the robot deployment in perspective, Bill added: “Ten years ago China´s robot density was 15 units only.”

Automation for Autos

As for where the robots are being used, Bill said that electrical and electronics accounted for 81,000 installations.

Notably: The automotive industry also showed a strong recovery in robot deployment. This was mainly driven by electric vehicle manufacturing in China. It rose by 89% in 2021 with 50,700 installations,” Bill said.

>>>

Mining for EV Minerals

Recycling can help minimize the amount of required mining. Ford and Redwood Materials, for example, are working on a closed-loop battery recycling plan. (Image: Ford)

Although battery plant announcements are frequent and impressive, the researchers at Benchmark Minerals pointed out earlier this month that those plants—and the vehicles they are to power—are may be more than a bit lacking in something that is crucial for their operational existence: materials availability.

Like graphite, lithium, nickel and cobalt.

They looked at the number of mines currently in operation, the amount of material produced by a mine on average, and the anticipated amount of materials for vehicles necessary in 2035.

And there is a whole lot of digging to be done.

- Lithium. Now about 678,000 tons are produced. 3,332,000 tons will be needed by 2035. If the average mine produces 45,000 tons per year, then there’s a need for about 74 new mines. Recycling could help reduce that to about 59 mines.

- Graphite. There are two types: natural flake and synthetic. For natural, 6,100,000 more tons will be needed, or 97 mines. This could be reduced if more silicon is used in anodes. For synthetic, there’s capacity for 2,100,000 tons now, 3,100,000 tons more are needed, so 54 more plants by 2035.

- Nickel and Cobalt. The amount of nickel will nearly double: there are 3,160,000 tons now and the number in 2035 is expected to be 6,200,000 tons. So with an average 42,000 tons per mine, 72 more mines are needed. As for cobalt, there will be 312,000 tons needed on top of the current 177,000 tons, so with an average of 5,000 tons per mine, that means 62 more. Again, recycling could reduce the number to 38 mines.

Which means as many as 359 new mines will be needed by 2035.

>>>

2023 Hyundai Palisade Calligraphy

Riding in comfort and style. (Image: Hyundai)

►The Hyundai Palisade appeared in 2019 as a MY 2020 three-row SUV. The brand’s flagship. For MY 2023 midcycle refresh they’ve upped up the number of flags. For a vehicle that’s up against segment stalwarts including the Toyota Highlander, Honda Pilot, Nissan Pathfinder and Ford Explorer, it acquits itself well. Very well.

►Although Hyundai has determined that 52% of those who have bought a Palisade are in the “Family” category, if the Empty Nester (27%) and Couple (14%) purchasers are combined, that’s a solid 41%, so while it is certainly a family vehicle, it isn’t only for hauling kids. In fact, in the context of the Palisade, “hauling” is not appropriate. “Conveying” might be better. And given the spaciousness, adults can be comfortably conveyed, too.

►The Palisade is the first Hyundai available with a WiFi hotspot (via Verizon). As the vehicle is large enough to feel like a room, that isn’t entirely surprising. That is, it offers 155.3 cubic feet of passenger volume and as for cargo, 86.4 cubic feet behind the first row, 45.8 behind the second and 18 behind the third.

►Another first. Yes, it has Apple CarPlay and Android Auto (and a 12.3-inch screen to access those, and other, functions). But the Palisade has Digital Key 2. One’s phone or smart watch can be used to for locking and starting functions. Hyundai has offered this in the past. Now it brings Apple into the environment for the digital key approach. “Keys” can be shared with iMessage (or Samsung Pass).

►Have you ever been surprised by a seat? While on my way from Detroit to Chicago the seat suddenly initiated a massage function. The Ergo Motion seat is meant to reduce driving fatigue, so it kicks on after a period of driving (yes, it can be deactivated). This is a thoughtful touch. (Better if you’re aware it will become activated.)

►Powertrain? 291-hp six mated to an eight-speed automatic. AWD is available.

►A friend talked about an “all-day car.” Something he’d be comfortable driving that long. That’s what the Palisade is. Even if it didn’t have the Ergo Motion seat.

>>>

About the Model C

Last-mile delivery robots are in production at a Magna plant in Michigan. (Image: Magna)

Magna is one of the world’s leading vehicle manufacturers that isn’t, well, a vehicle manufacturer per se. It is generally considered to be a supplier.

That said, Magna has built more than four million vehicles, everything from the Mercedes G-Class to the Toyota GR Supra.

Although most of that work is done at the company’s plant in Steyr, Austria, it has launched production of a vehicle of a different type at a facility in Troy, Michigan.

The Cartken Model C.

It is an autonomous robotic delivery vehicle.

Model C Specs

The Cartken vehicle is 27.9 inches long, 23.3 inches high and 17.9 inches wide. The dimensions of the cargo box are 16.1 inches long, 14.2 inches high and 11.6 inches wide.

The maximum payload is 31 pounds.

It has six wheels with brushless hub motors that are powered by a lithium-ion battery. The battery life is 10 hours.

The maximum operating speed is 5 mph. The average service speed is 3 mph.

The primary materials for the Model C are aluminum and thermo-formed plastic. (The interior of the cargo box is food-safe.)

The vehicles are fitted with cameras. Situations in the real world—which are inside or out, from malls to universities—are handled by machine learning and simultaneous location and mapping (SLAM)-based navigation algorithms.

Volume Expectations

The companies anticipate that thousands of the last-mile delivery robots will be built by Magna. As Christian Bersch, co-founder and CEO of Cartken, put it: “This partnership is a significant step toward scaling our business and getting more Model C’s into the world.”

Additionally, they anticipate that the vehicle’s platform will be used to create other variants.

>>>

Fashionable Color ( or Colour)

The New DS 3 launched at Paris Fashion Week. Naturellement. The car’s color: Diva Red. (Image: DS)

That photo above is certainly more fashionable than things we generally run.

The vehicle is the New DS 3 from DS Automobiles, a Stellantis brand. The New DS is the successor to the DS 3 Crossback.

The company emphasizes that the car is “built only at Poissy, in the Paris region.”

Face it: If someone says a car is built in Detroit, you think “industry.”

If someone says a car is built in Paris, you think “couture.”

And the New DS 3 was revealed this week, at the start of Paris Fashion Week.

DS has a longstanding partnership with the Fédération de la Haute Couture et de la Mode. Of course it does.

From a styling point of view the car has a new front fascia and LED headlamps. Particular attention was paid to the finish of the badges and a new Clous de Paris embossed insert was added (something that is more typical on exceedingly expensive watch faces than car logos).

Where Diva Red Came From

The car is available in seven body colors, one of which, Diva Red, is of particular interest.

Back in 2013 at the Shanghai Motor Show DS introduced a concept vehicle, Wild Rubis, which is red.

But not just a typical red.

It was created by putting on 11 layers.

Something you can do for a concept, but not a production car.

Diva Red is done with the conventional three-layer approach, base color, semi-transparent layer, protective laquer.

Apparently the rich red color is facilitated by a milling of the pigment, which also provides the “flop effect,” or the color appearing to vary depending on the angle it is viewed at.

On the Color

“We drew our inspiration from jewellery and gemology. The gem varies from the jewel through its great rarity and its captivating beauty. So we studied the intensity of the colour of rubies with the aim of developing the sensuality of a red, of a toffee apple and of spiced cherries. Our aim was to find a colour that reveals character, depth and saturation while adding a sparkling quality to induce emotion.”--Lisa Grangeon-Coudert DS Colours & Materials Designer

>>>

’24 Silverado: More Power. From a Diesel

2024 Chevy Silverado 3500HD LTZ dually. Workin’ for a livin’. (Image: Chevrolet)

Chevy sold 89,955 Silverado heavy-duty trucks during the first half of 2022.

Only Silverado light-duty pickups (169,561) and the Equinox CUV (116,678), outsold the Silverado HD.

Although there is plenty of buzz about the forthcoming Silverado EV, given the performance of the HD it isn’t entirely surprising that for MY 2024 Chevy has enhanced the truck with the objective of selling more of them.

There are:

- a comprehensive interior change for most models

- a standard Allison 10-speed transmission for both the 6.6-liter gas engine and 6.6-liter Duramax turbo diesel

- improved capabilities for the trailering technology

- exterior design changes including a new front fascia

- increased diesel output to 470 hp and 975 lb-ft of torque through things like a more-efficient turbocharger and a new piston bowl design

Yes, diesel.

When it comes to these brawny work trucks, diesels are a solid part of the plan.

And the same is the case for F Series and Ram HD.

Scott Bell, Chevy vice president, acknowledged that while EVs are coming, they are working to “strengthen the ICE products, a well,” adding, “We want to give customers a choice.”

EV pickups get the attention. Diesels still bring home the proverbial bacon.

>>>

Amazon Going to Efuels

However, not everyone is chuffed about diesels. . .

Like Amazon.

The company has announced that next year it will begin fueling part of its compression-combustion engines with electrofuels.

It has contracted with Infinium, a company that has been developing the process to combine green hydrogen (i.e., hydrogen created using renewable power) with recycled carbon dioxide waste to create efuels.

According to Robert Schuetzle, Infinium CEO, a two-step catalytic process is involved—and “Infinium has spent more than a decade developing its fuel production technology.” The efuel—which he says is a “drop-in replacement” for fuels including diesel—has an energy content that “is similar to that of its fossil-based alternatives.”

Infinium will construct a plant in Texas to produce the efuel.

Amazon will start using the efuel in its middle-mile fleet of trucks in SoCal next year.

Infinium will initially supply enough to power Amazon trucks at a volume that will allow five million miles of travel per year.

Although it is not zero-emissions, it is extremely close—and a move in the right direction.

Amazon intends to be net-zero carbon by 2040.

It has established a $2-billion investment fund for developing sustainable and decarbonizing technologies and services.

And part of that is an investment in Infinium.

>>>

And Something About Tesla

Bruce M. Belzowski, Managing Director-Automotive Futures, University of Michigan Transportation Research Institute, revealed some interesting findings in a study that he and his colleagues performed on what industry powertrain experts think about various aspects of Tesla.

As in:

- Asked about whether Tesla has an on-board computing advantage compared to traditional OEMs, 29% answered “Probably Yes” and 37% “Definitely Yes.” If that 66% combined isn’t compelling, add in the 13% that answered “Maybe” and it really seems Tesla is ahead.

- Asked about how long it will take the traditional to catch up to Tesla for that computing, 4% said less than a year, 33% answered one to two years, 44% believe it will be three to four years, 11% five to six years and 7% more than seven years.

- And probably being rather optimistic, when asked whether they think the traditional will “overtake Tesla once committed to an EV strategy,” 44% said “Probably yes” and 17% “Definitely yes.”

Consider:

According to CleanTechnica, in the first half of 2022 in the U.S. 102,834 Tesla Model Y vehicles were sold.

Summing all of the EVs sold in the first half by all of the traditional OEMs (Ford, Hyundai, Kia, Nissan, Chevy, Audi, Porsche, VW, Mercedes, BMW, GMC, Toyota), the number is 84,139.

All of those companies vs. one model.

RELATED CONTENT

-

On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.

-

Increasing Use of Structural Adhesives in Automotive

Can you glue a car together? Frank Billotto of DuPont Transportation & Industrial discusses the major role structural adhesives can play in vehicle assembly.

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

.jpg;width=70;height=70;mode=crop)