on Economics, EVs, Energy, & Things That Don't Start with "E"

Electric boat uses Polestar tech. . .water bikes boom. . .Geely brands to know. . .bear paws and snow tires. . .recycling carbon fibers. . .are automotive user interfaces any good. . .GM’s big manufacturing investment. . .Volvo XC60 Recharge review. . .

#economics

The More the Better: EVs and Economies of Scale

Candela C-8 electric hydrofoil uses the same battery pack and DC charger as the Polestar 2 providing Polestar with a bit more scale for its electric tech. (Image: Polestar)

“Product specific economies of scale are associated with the volume of output of any single product made and sold. In a multi-product firm or plant, product specific economies are often released by specializing in the manufacture of one or a few products over a larger scale of output.

“Such economies generally arise by avoiding the costs of interrupting production and re-tooling that is required in order to produce different products with the same machinery and equipment. Product specific economies are often the basis for specialization agreements.”--OECD

Ever wonder why nowadays all of those battery plants are “giga”?

There’s a reason why.

Another, more general, OECD definition:

“Economies of scale refers to the phenomenon where the average costs per unit of output decrease with the increase in the scale or magnitude of the output being produced by a firm.”

Keep that as well as the last sentence of the first definition (the “specialization agreements” bit) in mind when you consider this:

Candela Technology, a Swedish company that makes electric hydrofoils, and Polestar have entered an agreement wherein the auto manufacturer will be providing the boat producer with the same 69-kWh battery pack and DC charging technology as are used in the Polestar 2, standard range, single motor.

This will provide the Candela C-8 with an expected range of up to 57 nautical miles at a cruising speed of 22 knots. (The setup in the Polestar 2: 297 miles.)

Why This Matters

Thomas Ingenlath, CEO of Polestar, said of the agreement: “Sharing know-how on batteries and vehicle engineering with Candela will help reach our shared goal of transitioning to a future where all forms of transport are sustainable.”

It is worth knowing that the global electric boat market is expected to have sizable growth. Research firm The Insights Partners said that the global market was $5.26 billion in 2022 and is expected to be $11.35 billion in 2028.

So there is certainly scale.

Speaking of which. . .

Here is part of the descriptive boilerplate about Polestar:

Polestar Automotive Holding UK PLC (Nasdaq: PSNY) (“Polestar”) is a Swedish premium electric vehicle manufacturer. Founded by Volvo Car AB (publ.) (together with its subsidiaries, “Volvo Cars”) and Zhejiang Geely Holding Group Co., Ltd (“Geely”), in 2017, Polestar enjoys specific technological and engineering synergies with Volvo Cars and benefits from significant economies of scale as a result.

Scale.

///

A Mode of Transportation with a 25% CAGR?

This is the Hydrofoiler SL3, launched last fall by Manta5, a New Zealand-based company that claims to be the creator of the world’s first hydrofoil bike. As a hydrofoil, when moving the operator is above the water surface. According to Manta5 to accomplish that sustained elevation, about 400 Watts continuous are required and, as the company puts it, “Unless you’re training for the Tour de France, very few can maintain that level of physical output for an extended duration.” So the carbon-fiber and aluminum structure has a 2.5-kW electric motor that, with pedal assistance, can provide a 4.5-hour ride time.

Speaking of water. . .

Admittedly this isn’t “automotive” per se, but perhaps a form of micromobility. . .

- The global water bikes market was an estimated $24.2-million in 2022 and research firm Fact.MR projects that it will grow at CAGR 25% and will reach $225.8-million by 2032.

Perhaps no surprise

Electric water bikes are a focus of water bike manufacturers. In terms of design, hydrofoils are also a keen area of interest. Both make operating water bikes easier.

Given that an estimated 69.5% of the 2022 market were rentals, easier is undoubtedly better.

///Geely Names to Be Aware Of

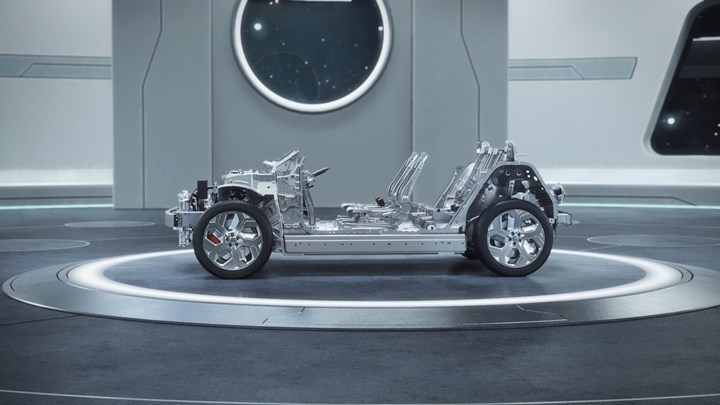

The Geely SEA-2 architecture is not only being used to underpin Volvo and Polestar models, but the company is offering it for license to other automakers. This provides additional scale. (Image: Geely)

It has been around as a company since 1986 and its automotive business was launched in 1997:

Zhejiang Geely Holding Group

The China-based company’s brands include some that you are familiar with:

- Volvo Cars (see item below)

- Lotus Cars

- Polestar (see item above)

- smart

Then there are brands that you may not have heard of:

- Lynk & Co

- Geometry

- Livan

- ZEEKR

- Proton Cars

- Farizon

- LEVC

- Radar Auto

Geely Holding announced its brands delivered more than 2.3 million units in 2022, an increase of 4.7% over 2021.

Some Things to Know

- Lynk & Co is focusing on a subscription model in Europe. It now has more than 180,000 members, an increase of 145%. It operates in seven countries: Netherlands, Sweden, Germany, France, Italy, Spain, and Belgium.

- Geometry is a mass-market EV-only brand. Among its global markets are Eastern Europe and South America. It had a sales increase of 170% year-over-year to 149,389 units.

- Livan is a battery-swapping EV brand. In its first year of sales it sold 56,140 units.

- ZEEKR had sales of 71,941 vehicles in 2022, its first year of sales of luxury EVs.

- Farizon is dedicated to commercial vehicles. It is in the “new energy light truck category,” and offers battery electric and even heavy-duty trucks that run on methanol. It has extended its sales to the Middle East and South America.

- LEVC is the company that makes electrified versions of the classic British black cab. It also builds commercial vans. It had a sales increase of 67% in 2022 and plans to grow 20% in 2023 with “smart, green, safe and accessible mobility solutions to more people around the world.”

Data Point

In 2022 the group’s sales of electrified and alternative fuel vehicles doubled to approximately 675,000 units, or 29% of sales.

Overall, Geely Holding has had sales of more than 2 million units for five years running.

///

Of Burrs and Bears

An examination of bear paws led researchers to find designs that can benefit snow tires. (If you want to see some polar bears—close, but not close enough to see the intricacies of the paw configuration—go to the Detroit Zoo, the source of this image.)

The story of the invention of Velcro is fairly well known:

Inventor George de Mestral was on a hunting trip in 1941 in Switzerland. He noticed that there were burrs on his clothing and his Irish Pointer’s fur from a burdock plant.

Rather than doing what most of us would do—brush them off with annoyance—he took some home to study under a microscope. (Unlike most of us de Mestral had also filed for his first patent when he was 12, so we shouldn’t feel badly about our comparative lack of curiosity. He was 34 when he was on that famous walk through the brush.)

The the burrs resulted in Velcro.

Which leads us to now and to a team of researchers associated with the University of Akron in Ohio.

And to polar bears.

Ali Dhinojwala, the H.A. Morton Professor of Polymer Science in the School of Polymer Science and Polymer Engineering:

“We had an ongoing project for many years focused on ice; we were looking at the friction of materials and we were interested in this topic because we are in Akron and our national partners need to develop tires with a strong grip on the road in ice and snow conditions.

“Nate had an interest in how nature has adapted to this solution for snow. The example that came to his mind was polar bears—and the research began from there.”

Peering at Paws

The team looked at the paw pads of polar bears.

They determined that there are papillae (little bumps) on the paws of polar bears that are up to 1.5 times taller than those on other bears.

Even though polar bear pads are smaller than those of other bears, their taller papillae result in a 30 to 50% increase in frictional shear stress—which means better traction.

Dhinojwala pointed out, “If you look at snow tires you will see that they do have some deeper treads, but this research could also show various ways to design them that could have a larger impact.”

The aforementioned Nate is Nathaniel Orndorf, a 2022 Ph.D. graduate.

He is now employed as a senior material scientist at Bridgestone Americas.

The research was published in the Journal of the Royal Society Interface.

Somewhere de Mestral is smiling.

///

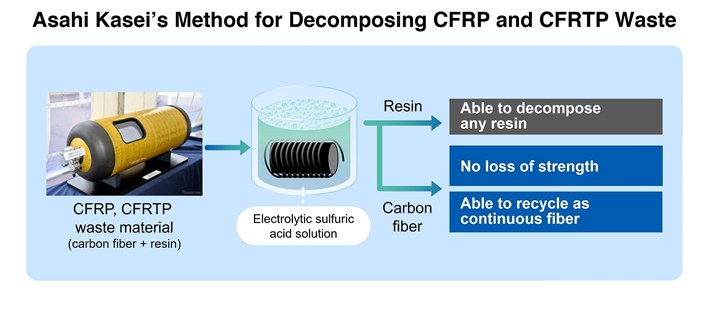

Recycled Carbon

Asahi Kasei carbon fiber recycling process allows the reuse of fibers without a property degradation. (Image: Asahi Kasei)

Carbon fiber reinforced plastics (CFRP) are appealing for automotive applications because the materials are both light and strong.

The mechanical properties are good.

The financial properties (a.k.a., cost), not so good.

There is another aspect of CFRP that has not been so good: the recyclability of the materials.

Getting the carbon fibers—the really expensive thing—out of the resin is challenging.

So the current processes chop up the fibers.

Consequently, the fibers used in subsequent applications are less high-performing compared with the long strands.

A recycling process that allows carbon fibers to be removed from CFRP (and carbon fiber reinforced thermoplastics, CFRTP) so they can be reused without a degradation in their properties has been developed by material supplier Asahi Kasei and partners at the National Institute of Technology at Kitakyushu College and the Tokyo University of Science.

It's called the “electrolyzed sulfuric acid solution method.”

Asahi Kasei describes it as “an inexpensive, circular solution to the end-of-life dilemma of carbon fiber plastic compounds.”

Evidently part of the solution of the end-of-life is to keep it going without giving up anything in the way of properties.

Where It Is At Right Now

Although the process is currently being run in a laboratory setting, an Asahi Kasei spokesperson says that they are anticipating it being used to process larger quantities of material within about two years and they are planning facilities that will be able to handle tons of material per year.

Notably. . .

The recycled material is:

- 1/3 to ½ the price of virgin material

- The energy required is 1/10 that of virgin fiber

///

The Interface Is the Thing

Steven Sinofsky, current Andreessen Horowitz board member and once president of the Microsoft Windows division, visited CES (apparently all of it) and wrote up his impressions in a Medium post.

This is, in part, what he had to say about the vehicles he looked into:

“What is interesting is that much like TVs that continue to have poor software experiences we don’t need, the presence of the big screen in all these EV models is driving a move to have no physical controls. This feels ‘Apple like’ and of course Tesla-like but we’re also facing surprising increases in motor vehicle accidents in the US even with the pandemic. Is this because of phones or are screen user interfaces contributing? And given that car makers took decades to hone the physical UI are they going to take a decade to hone a digital UI [user interface]? I’m worried.”

The screens in vehicles may be getting bigger. But it doesn’t mean that they are necessarily better—or safer, it seems.

///

What Does $918 Million Mean?

GM’s executive vice president, Global Manufacturing and Sustainability, Gerald Johnson says the $918-million manufacturing investment will help with V8 and EV component production. (Image: GM)

When you read about investments in manufacturing facilities like the one GM made last week, it is probably something for which you have no context and so you shrug.

So let’s provide a bit of context.

GM announced the investment of $918 million in four U.S. plants.

- Flint [Michigan] Engine Operations is getting $579 million for the assembly of the forthcoming sixth-generation family of Small Block V8 engines. Machining capacity of blocks, cranks and heads will also be added.

- Bay City [Michigan] GPS gets a $216-million investment for camshafts, con rods, and block/head machining to support the Flint plant.

- Defiance [Ohio] Operations is receiving a $55-million investment. Of that, $47 million will go for various block castings for future V8 engine programs. $8 million will be used to build a casting development cell for future electric vehicle components.

- Rochester [New York] Operations is getting a $68 million investment. Of that, $12 million will go for the production of fuel rails and intake manifolds for the future V8s. $56 million will go for the production of EV battery pack cooling lines.

“V8s?” you wonder.

Gerald Johnson, GM executive vice president, Global Manufacturing and Sustainability:

“We are announcing significant investments to strengthen our industry-leading lineup of full-size pickups and SUVs by preparing four U.S. facilities to build GM’s sixth generation Small Block V-8 engine.”

Yes, they will still be making a lot of ICE trucks and utes.

But the $64 million in the Defiance and Rochester plants for EVs is not insignificant, so let’s not think the whole EV undertaking is going back-burner.

Back to the context

According to the 2023 Capital Spending Survey that projects spending on machine tools and associated equipment conducted annually by Gardner Intelligence, U.S. manufacturing companies—from the smallest to the largest—are projected to spend a total $7.01 billion.

This announcement from GM is 13% of all of that projected spend.

Yes, a lot of money.

///

Surprising Implications of Autonomous Vehicle Emissions

Let’s assume that the technology gets worked out and there are truly autonomous vehicles (AVs) almost everywhere.

Let’s say it is 2050 and there are one billion AVs out there. (A bit of a stretch given that there are about 1.4 billion vehicles of a non-autonomous nature on the global streets right now, so the car PARC would have to undergo quite a transition.)

MIT researchers have done some math with a surprising result. They figure that 840 W are needed by the computer that permits vehicular autonomy. So, the one billion AVs drive for one hour.

That would result in the generation of the same amount of emissions as all of the data centers in operation today do. (You read that right.)

That’s 0.3% of global greenhouse gas emissions—as much as Argentina produces annually.

Running Some (Big) Numbers

While it is easy to visualize a data center using a lot of electricity and therefore generating emissions, it may be difficult to apply that to cars and crossovers.

The MIT researchers took a common function of an AV: running 10 cameras and then processing that information on 10 deep neural networks.

If a car doing that runs for an hour, 21.6 million inferences are made per day.

If there are one billion vehicles doing that, there are 21.6 quadrillion inferences.

Bringing this back to data centers, according to the researcher, all of Facebook’s data centers—all of them—make a few trillion inferences a day.

And the vehicles’ are doing quadrillions (1 quadrillion = 1,000 trillion).

The Solution?

The researchers have a couple of recommendations to mitigate this. They calculated that it is necessary that each AV consume less than 1.2 kW of power for computing.*

So one suggestion is to greatly improve the efficiency of computing hardware: a doubling of efficiency every 1.1 years.

Another is to develop more efficient algorithms to run on that hardware.

Neither, apparently, is easy.

Better Forewarned

“If we just keep the business-as-usual trends in decarbonization and the current rate of hardware efficiency improvements, it doesn’t seem like it is going to be enough to constrain the emissions from computing onboard autonomous vehicles. This has the potential to become an enormous problem. But if we get ahead of it, we could design more efficient autonomous vehicles that have a smaller carbon footprint from the start.”--Soumya Sudhakar, a graduate student in aeronautics and astronautics.

Sudhaker is the first author of a paper written along with Vivienne Sze and Sertac Karaman that appears in the January-February issue of IEEE Micro.

==

*You may have noticed the 840 W and the 1.2 kW figures: it would seem that vehicles would be using less than the suggested 1.2 kW, so what’s the point of the recommendation?

We asked. and Soumya Sudhakar explained: “The emissions from running the computers onboard autonomous vehicles can be modeled as a function of the number of autonomous vehicles, the time each autonomous vehicle spends driving, the computer power, and the carbon intensity of the electricity consumed by the computer. If we know these variables exactly, we can directly calculate the computer power needed to constrain emissions to a certain baseline.”

She continued with an example: “We assume 1 billion autonomous vehicles that are driven one hour a day and carbon intensity to be equal to the 2020 global average carbon intensity, and find it would take computer power to be 840 Watts for emissions to equal that of all data centers.”

However, she pointed out that they don’t know precisely what the variables will be, so they probabilistically modeled each variable.

“In our probabilistic model based on current information for each variable, we sample one million scenarios and find in over 90% of the scenarios, the computer power was under 1.2 kW for emissions to be equal to data centers.”

///

2023 XC60 Recharge eAWD Ultimate Dark

This Volvo plug-in hybrid provides plenty of miles before you have to visit a gas station which, especially in winter (and they know a lot about winter in Sweden, from which this SUV hails), is a good thing. (Image: Volvo)

The Volvo XC60 Recharge eAWD is the sort of vehicle that you really want during the winter weather. (You may want it during the other three seasons, too, but winter is a real boon.) The reason is not only because of the all-wheel-drive capability that this five-passenger crossover provides, but because it is a plug-in hybrid.

This means the vehicle is going to provide approximately 35 miles of pure electric range. According to the U.S. Federal Highway Administration, the average American drives 13,476 miles per year. So that would divide in 36.9 miles per day. Let’s call it 37 miles. The average driver would then find themselves in the XC60 Recharge eAWD driving two miles per day on gasoline alone before going home and plugging in the 14.9-kWh battery (which can be charged from 0 to 100% with a 240-V system; Volvo has a partner, Qmerit, that will install your home system) . The vehicle provides an estimated 28 mpg from its 455 hp 2.0-liter intercooled turbo I4 and hybrid system. So this means that you can drive for two weeks and use only one gallon of gas. Given that it has an 18.8-gallon fuel tank you could spend the better part of the winter not having to visit a gas station.

Realize that this is a fully equipped crossover, not something small and spare. It measures 65.3 inches high, 78.7 inches wide and 185.4 inches long. It provides 63.3 cubic feet of cargo room (second row down). It has a maximum towing capacity of 3,500 pounds.

Volvo had been using its Sensus system for infotainment purposes in it vehicles. It (wisely) has started working closely with Google. The XC60 uses the Android Automotive infotainment system, so there are Google Maps, Google Assistant and even Google Play accessible on the nine-inch center display. (Fear not CarPlay users: it’s in there.) When you opt for something special in terms of entertainment, there is a Bowers & Wilkins 15-speaker system that really makes Abba sound all the better. (Let’s not overlook that this crossover hails from Sweden.)

As regards the design, there are some people who like Scandinavian design and some who don’t. While the exterior Volvo designs are certainly less rectangular than they once were, there is no mistaking the XC60 for something from another marque.

And while the interior isn’t full-on minimalism by any sense, it is worth noting that the interior of any Volvo has always had a focus on ergonomics for the driver and passengers, which is a wonderful thing.

Even more wonderful than not having to stand at a gas pump very often during the winter.

RELATED CONTENT

-

Kroger Tests Self-Driving Grocery Delivery Service

The Kroger Co. and Silicon Valley startup Nuro launched a pilot program for autonomous grocery delivery this week in Scottsdale, Ariz.

-

Tesla Offers Free Autopilot Trials

Tesla Inc. has begun offering free two-week trials of its semi-autonomous Autopilot technology to owners of its Model 3, S and X electric vehicles who haven’t already purchased the system.

-

Flying Car Flight of Fancy Gets Real

People have been dreaming about flying cars since the early days of the auto and aircraft industries.

.jpg;width=70;height=70;mode=crop)