Freudenberg Doubles Up on Battery Pressure Controls

Non-woven fabrics enhance permeability and water tightness

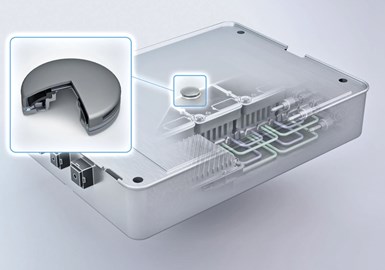

Freudenberg Sealing Technologies (FST) has launched production of a pressure compensation element for electric-vehicle batteries that combines the functions of two separate units used in current electric vehicles.

Images: Freudenberg

Dubbed DIAvent, the integrated valve helps release excess pressure during normal operations and provides emergency venting in the event of an accident or severe damage.

The system is cheaper and easier to install than current dual-valve pressure equalization systems, according to the supplier.

How it Works

The patented valve replaces typical microporous film—such as polytetrafluoroethylene—with a blend of two nonwoven materials with different properties: air permeability and water tightness.

A water-repellent fabric on the outside layer of the valve allows air exchange rates of 8 liters per minute with minimal pressure differences and protects against 100 mm of water. If the water pressure rises above this, a second inner layer of nonwovens is activated so that no water can enter the housing.

In Case of an Emergency

If the pressure in the housing exceeds the atmospheric air pressure by more than 50 millibars, emergency degassing is initiated. At this level, an umbrella valve opens and can discharge gas at 40 liters per second.

At the end of the process, the valve automatically closes to make it easier to remove a damaged battery, FST says.

The automated open and closing capability also supports pressure equalization in normal operation, such as when batteries with high energy density are exposed to rapid temperature fluctuations.

Only a few liters of air per minute are exchanged in both directions during normal operation. But in an emergency, the entire quantity of gas emitted from a defective cell must be removed in a few seconds. Otherwise, FST says, the internal pressure could cause the housing to burst.

Ready for Action

FST introduced the technology earlier this year in Volkswagen’s e-Caddy and e-Transporter electric cargo vans sold in Europe and Mexico.

FST battery pressure valve in BEJV’s new electric crossover vehicle

High-volume applications now are ramping up in China with the ArcFox electric crossover vehicle produced by Beijing Electric Vehicles, BAIC’s EV joint venture.

The supplier says it also has development programs with several other customers and expects to announce additional contracts year-end.

FST expects demand for the integrated system will increase as higher energy density batteries are introduced. Such batteries increase the amount of gas that has to be quickly removed in case of an emergency, as well as the amount of air exchanged during normal operations.

RELATED CONTENT

-

On Fuel Cells, Battery Enclosures, and Lucid Air

A skateboard for fuel cells, building a better battery enclosure, what ADAS does, a big engine for boats, the curious case of lean production, what drivers think, and why Lucid is remarkable

-

On Electric Pickups, Flying Taxis, and Auto Industry Transformation

Ford goes for vertical integration, DENSO and Honeywell take to the skies, how suppliers feel about their customers, how vehicle customers feel about shopping, and insights from a software exec

-

Things to Know About Cam Grinding

By James Gaffney, Product Engineer, Precision Grinding and Patrick D. Redington, Manager, Precision Grinding Business Unit, Norton Company (Worcester, MA)