Laser Blanking Line Means Significant Material Save

Increase production and save material. Seems like a double win for the sheet metal shop.

#aluminum #robotics

Although using a laser for blanking operations is not out of the ordinary, a new approach developed by Schuler—called “Dynamic Flow Technology”—can make a significant difference when it comes to saving materials by minimizing scrap.

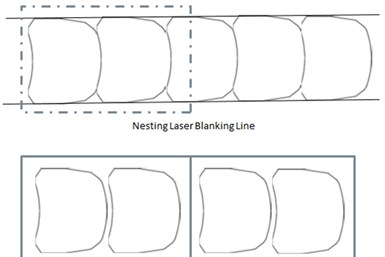

- Typical flatbed laser blanking is performed on rectangular blanks. This can result in scrap of approximately 2.4-inches per side. Also, for purposes of robotic scrap separation and stacking, there is typically a scrap grid width of 0.8 to 1.2-inches around the part.

- With that, assume a blank to produce two hoods on the flatbed laser. It would require a blank measuring 89 x 87 inches.

- The Dynamic Flow Technology (DFT) allows the hoods to be cut directly from a coil. To cut the same hoods a feed length of 81 inches and a coil width of 85 inches would be required.

- For the two hoods, the amount of scrap savings using the DFT compared to the flatbed method is approximately 11%.

Note the material savings that can be achieved by using the Dynamic Flow Technology approach vs. flatbed laser blanking. (Images: Schuler)

Schuler also says that DFT is faster than the flatbed laser, resulting in more parts per minute.

- A flatbed laser can produce three hoods per minute.

- The DFT approach can produce up to 35 hoods per minute, or some 1,700 per hour (with an overall equipment efficiency of >80%).

The Schuler line for processing parts like aluminum hoods.

RELATED CONTENT

-

On Electric Pickups, Flying Taxis, and Auto Industry Transformation

Ford goes for vertical integration, DENSO and Honeywell take to the skies, how suppliers feel about their customers, how vehicle customers feel about shopping, and insights from a software exec

-

Increasing Use of Structural Adhesives in Automotive

Can you glue a car together? Frank Billotto of DuPont Transportation & Industrial discusses the major role structural adhesives can play in vehicle assembly.

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

.jpg;width=70;height=70;mode=crop)