Industrial Robot Use Hits All-Time High

U.S. robot use in 2019 up but slowed. China dominates deployment

#robotics

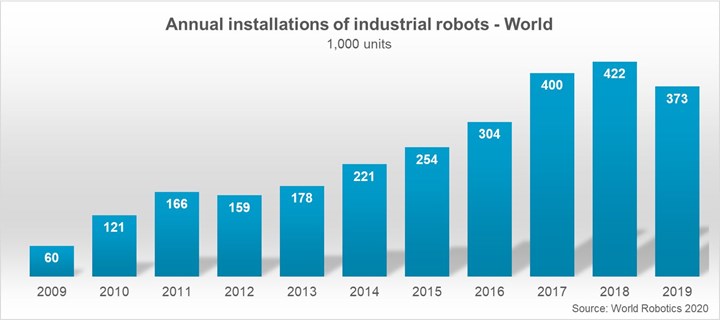

There are now 2.7-million industrial robots at work around the world in factories. This is an increase of 12%, according to the World Robotics 2020 Industrial Robots report from the International Federation of Robots (IFR).

Working with a Kuka cobot. (Image: IFR)

According to Milton Guerry, IFR president, “The stock of industrial robots operating in factories around the world today marks the highest level in history.”

While that fact isn’t necessarily surprising (what would be surprising is if the number was the lowest in history), what is remarkable is that Guerry said that there has been a worldwide increase of about 85% in robotic automation between 2014 and 2019.

China leads the installation base, adding 783,000 units in 2019, so that it now has 1,405,000 robots running. Some 71% of the new robots were imported to China, and of that, 29% were delivered to the auto industry.

The US added about 7%, or 293,200 units. However, according to the IFR, installations in the U.S. slowed by 17% in 2019, compared with a record year in 2018.

(Source: IFR)

The IFR points out that most of the robots in the U.S. were imported from Japan and Europe.

Speaking of Japan and Europe, Japan is second to China in Asia, with an increase of 12%, 355,000 units. And Germany is a robust user of robots. With an operational stock of some 221,500 units, it has three times that of Italy (74,400), five times the number in France (42,000) and 10 times (!) the number in the U.K. (21,700).

A global trend IFR has identified is the deployment of collaborative robots. Compared to 2018 there was a growth of 11% for cobots in 2019, or 18,000 units.

Although the IFR acknowledges that COVID-19 will have a “strong impact” on the numbers for 2020 in the wrong direction, it stresses that a key advantage of robots remains the same: “Automation enables manufacturers to keep production in developed economies—or reshore it—without sacrificing cost efficiency.”

Someone might want to bring this to the attention of the British, because when (if?) Brexit occurs, they’re going to need the kind of efficient manufacturing capabilities that robots provide.

RELATED CONTENT

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

-

Multiple Choices for Light, High-Performance Chassis

How carbon fiber is utilized is as different as the vehicles on which it is used. From full carbon tubs to partial panels to welded steel tube sandwich structures, the only limitation is imagination.

-

The Koenigsegg Jesko Has An Amazing Engine

It is hard to believe that this is a vehicle in “serial” production with such extraordinary powertrain performance

.jpg;width=70;height=70;mode=crop)