Creating a Low-Cost Chassis Architecture

The engineers at Zenos Cars have combined recycled carbon fiber, drinking straws and aluminum to create a chassis for a low-volume sports car.

#aluminum

The construction method looks vaguely familiar: a backbone frame over which is draped a composite body.

And while this chassis does carry overtones of every Lotus street car from the Elan to the Esprit, it is so different that it has already caught the eye of at least one major OEM. That’s because the architecture Zenos Cars of Norfork, England, has created for its E10 road-legal track car is modular,flexible, designed for repairability, and built around an anodized aluminum backbone married to a multi-piece recycled carbon fiber cockpit.

Ansar Ali and Mark Edwards, both Lotus alumni and fresh from running Caterham Cars, saw the gap in the marketplace opened up by Lotus moving upmarket, and Caterham increasing its production volume.

Working under the codename “Project Silver,” Ali and Edwards wanted to build an all-composite chassis. They engaged Antony Dodworth, the former Principle Research Manager, Carbon Fiber for Bentley, and Larry Holt, CEO of Multimatic, to engineer the vehicle.

It didn’t take long before Dodworth and Holt realized that Ali and Edwards didn’t have the budget to build the car they desired. Says Ali: “We built the car backwards knowing that we had to make X as a business, which left Y for manufacturing costs, and Z for the bill of materials. And that last number had to deliver a fun, affordable sports car.” Undeterred, Edwards thought back to a blog posting he had read about restoring a classic Lotus Elan, and began to put the pieces together.

According to Dodworth, Edwards soon came to him with a different proposition: “He asked if we could make the floor, sides and bulkhead in composite, and use an aluminum spine to hold the engine and suspension. I told him it wouldn’t be a problem.”

Dodworth’s recycled carbon fiber material arose out of work first begun for Bentley and BMW. At the former, he spent six years developing discontinuous carbon fiber plastic (DCFP), making items like the chassis rails from the material. Later, with BMW, he accepted a challenge from the German automaker and SGL, its carbon fiber supplier, to take the remnants of continuous carbon fiber production (“It looked like barber shop floor sweepings,” says Dodworth) and turn it into usable material. Dodworth invented a “gun” to shoot the material onto a belt with a carrier placed between the upper and lower layers of carbon fiber.

Unfortunately, the deposition rates were very slow, and it was necessary to knit the surfaces together like a layer of fleece. “With discontinuous material,” he says, “there isn’t any capillary action to take the resin down the capillary gap. It looks and acts like blotting paper with the resin just sitting on the surface.”

Dodworth continued to work on the problem until he came up with a novel solution: McDonald’s drinking straws. “I went into a local McDonald’s, grabbed a handful of drinking straws, glued them together with super glue, and chopped them to a uniform thickness,” says Dodworth. “We could have used any plastic we wanted, but we wanted one with a fairly high melt temperature, and recycled polycarbonate”—as in the straws—fit the bill.” The straws separate the recycled carbon fiber skins, connect the top skin to the bottom, and act as I-beams. The completed material’s modulus is 97%-98% that of continuous carbon fiber, and its tensile strength is 60%-70%, though—as Dodworth points out—“This isn’t the wing of a Boeing 787, it’s a car, a five-sided shoebox, where stiffness is the most important factor.” Even more impressive is the fact that the DCFP panels are about 1/10 the cost of continuous fiber items, and have Class A surfaces.

Each panel is formed in an inexpensive hot aluminum die where two rectangles of DCFP are clamped in place with a single 20-mm polycarbonate core in-between. Resin is sprayed on each side of the sandwich, and the die is closed to form the panel to its final shape. The whole process takes 12 minutes. A flange of compressed material approximately 6.0-mm thick around the edge of the panel acts as both a barrier to water intrusion and a bonding surface for joining the panels together. Unlike a continuous carbon fiber tub, the DCFP panels used by Zenos can be replaced after a major accident.

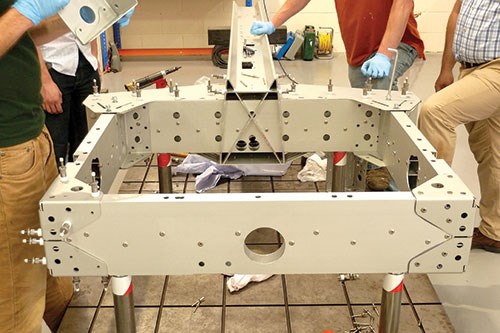

Zenos takes delivery of the panels for the front and rear bulkheads, sides, and floor, and bonds them together around the aluminum beam. This single-piece extrusion is 2.1-meters long, was optimized using FEA by Multimatic, and is the main source of the car’s torsional rigidity. “The panels butt up against one another in a simple jig,” says Ali, “and are adhesively bonded, with mechanical fasteners used in tear-prone areas. We place a thin sheet of fiberglass between the bottom of the aluminum beam and top of the floorpan to prevent any galvanic corrosion between the two materials, before bonding the floor to the bottom of the beam.” Hidden behind the DCFP side panels are tubular steel impact bars that connect to the similarly constructed rollover hoop. The side impact bars are hidden from sight by the interior closure panels.

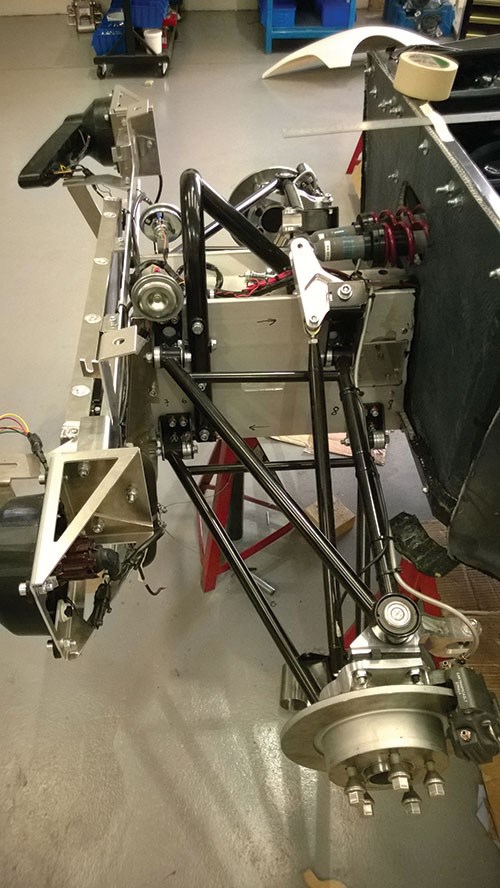

A U-shaped rear subframe carries the powertrain (a 200-hp, naturally aspirated Ford 2.0-liter four cylinder mated to either a five- or six-speed manual transmission), and is built up from extrusions. Each corner of the subframe is both bonded and mechanically fastened, and then bonded and mechanically affixed to the transverse section of the main beam.

The front dampers are located atop the spine, and are actuated by extra-long wishbones, pushrods and rockers. “It’s not because we wanted to emulate a Formula One car or deliberately minimize unsprung weight,” says Ali.

“We wanted to protect a relatively expensive component that might have to be replaced in an accident. In our design, the suspension arms become sacrificial members, and this helps reduce the running costs of the car over its lifetime.”

The first two prototypes are currently undergoing testing in England. They have been pavé tested at the Millbrook Proving Ground, run at speed for long periods at the Snetterton race track, and are taken home at night and over the weekends by Zenos employees, including Ali and Edwards, for on-the-road evaluation. A test session at Millbrook at the end of August allowed depositors to get their first run in the car, and provide feedback. Final development began in September, leaving just four months to complete this process before production begins in January 2015.

Ali and Edwards plan to build 150 to 200 cars in the first year from their 7,000 ft2 in Wymondham, just down the road from Lotus headquarters in England.

Currently, the company consists of 12 people including Ali and Edwards, a design engineer, a body engineer, the head of operations, and a finance person. By the start of production, there will be approximately 10 production people who will work in four teams of two in separate assembly bays, with two team leaders floating between vehicles. As production rises, more will be added, though the group is focused on improving productivity at each step to keep headcount under control.

Sixty-five hours have been budgeted to build each E10, though Ali expects this number to drop to 50 to 55 hours as the teams gain experience with the process.

Central to this process, and the company’s profitability, is the fact that the E10 production car has no doors.

“Doors are problematic and can be the death knell for any niche manufacturer,” says Ali. “It was a lower risk and took less investment to build the first one as a step-in car instead of taking chances with a new product, a new process, and a new workforce. You can’t put on the order form an option for ‘doors that work’.” The next step is to build E11 in 2016. It is a new car in that it adds doors to the E10 concept, and makes the E10’s optional windshield and wipers standard equipment. It will be followed one year later by E12, which adds a fixed roof, front and rear crash structures, and airbags. As if to sum up these plans, Ali states: “We are learning to crawl at the moment, and will then move on to walking before we learn to run.”

Mass Market DCFP

Ask Antony Dodworth about using his DCFP panels for vehicle light weighting, and he’ll warn you that, “This is a lot lighter than and as cost-effective as aluminum, but only if you start with a clean sheet design.” Using continuous carbon fiber, or what Dodworth describes as “making things monolithic,” makes a design a little bit lighter, but tremendously more expensive.

Further, trying to adapt a “black metal” design to DCFP will fail because you need a greater section thickness to use the benefits of the low-cost composite.

“The construction method is familiar: it’s still a press and a piece of tooling,” says Dodworth.

“However, you only need one heated aluminum die versus three to four tool steel dies for steel panels or five for aluminum.” To take advantage of its properties—both mechanical and cost—he says it’s necessary to get designers and engineers into the same room early in the process. “It takes some cleverness to design parts you can make, and some compromise from both the stylists and the engineers to get them to look right and be manufacturable. Yet, if you work together during development, you both end up with something with which you are happy.”

RELATED CONTENT

-

Light Rider

When you think of the forthcoming LA Auto Show and Los Angeles in general, you may think of (1) very expensive, very large vehicles being piloted by very egotistical stars and (2) very jammed freeways full of the aforementioned, as well as numerous other vehicles of a less ostentatious variety.

-

The Koenigsegg Jesko Has An Amazing Engine

It is hard to believe that this is a vehicle in “serial” production with such extraordinary powertrain performance

-

On The Toyota Corolla Cross, Hyundai Santa Cruz, and VW Subscriptions

How to charge an autonomous vehicle. Toyota adds a new crossover. VW gets into the subscription business. Hyundai goes Santa Cruz. And more.