Building Bikes

According to the folks at Sculpteo, a 3d printing and engineering services company based outside of Paris, they built what they describe as “the first ever fully functional bike created using digital manufacturing.” To prove that this is a real bike, not a booth exhibit, the two designers of the bike, Alexandre d’Orsetti and Piotr Widelka, rode it from Las Vegas, where it had been on display at CES, to San Francisco, where Sculpteo has a facility.

According to the folks at Sculpteo, a 3d printing and engineering services company based outside of Paris, they built what they describe as “the first ever fully functional bike created using digital manufacturing.”

To prove that this is a real bike, not a booth exhibit, the two designers of the bike, Alexandre d’Orsetti and Piotr Widelka, rode it from Las Vegas, where it had been on display at CES, to San Francisco, where Sculpteo has a facility.

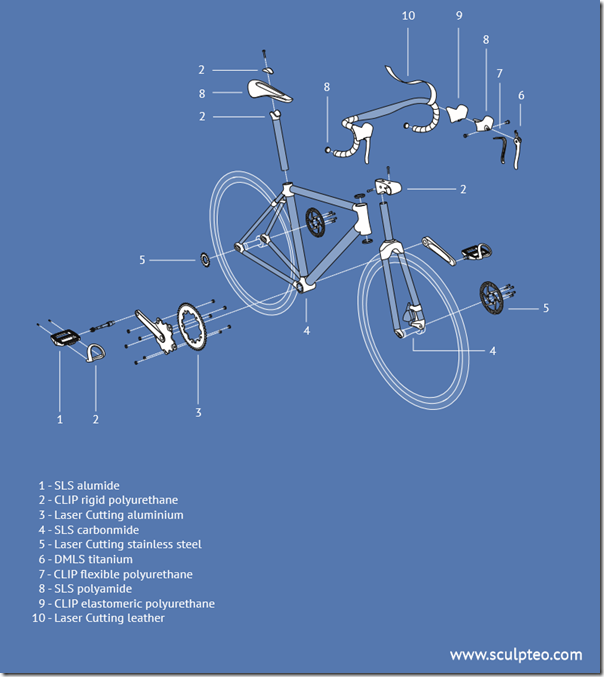

According to Sculpteo, 70 percent of the parts on the bike were 3D printed. These include:

· Pedals, made in aluminide with selective laser sintering (SLS)

· Connectors for the pedals, saddle, and handlebars from rigid polyurethane with continuous liquid interface production (CLIP)

· Connection parts for the frame in wheels with SLS

· Brake parts in titanium with direct metal laser sintering (SMLS)

· Brake parts in flexible polyurethane with CLIP

· Brake parts in elastomeric polyurethane with CLIP

· Saddle and other brake parts in polyamide with SLS

According to d’Orsetti, they decided to outsource some of the bike elements that didn’t lend themselves to Sculpteo’s equipment, including the cables, brake cases and clamping bracket.

The bike cost less than $4,000 to produce.

However, it required seven weeks to design and build.

Certainly, the bike is carefully crafted, but still, seven weeks seems a bit long.

So while not exactly an apples-to-apples comparison, we found Mission Bicycle Company in San Francisco, which hand-builds bikes in its facility on Valencia Street. Admittedly, the 4130 chromoloy steel frame is produced in a factory in Taiwan and shipped, unpainted, to San Francisco, where it is powder coated.

All of the elements are put together to build a bike that is assembled to order, with a starting price of $999 and a delivery time within four weeks.

To be sure, a largely 3D printed bike is impressive, but there are still time and cost gaps that need to be addressed.

RELATED CONTENT

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

-

On Fuel Cells, Battery Enclosures, and Lucid Air

A skateboard for fuel cells, building a better battery enclosure, what ADAS does, a big engine for boats, the curious case of lean production, what drivers think, and why Lucid is remarkable

-

Increasing Use of Structural Adhesives in Automotive

Can you glue a car together? Frank Billotto of DuPont Transportation & Industrial discusses the major role structural adhesives can play in vehicle assembly.

.jpg;width=70;height=70;mode=crop)