Aluminum Sheet for EV Battery Enclosure

As the number of electric vehicles (EVs) is about to increase almost exponentially, aluminum supplier Novelis is preparing to provide customers with protective solutions

#hybrid #aluminum

As the number of electric vehicles (EVs) is about to increase almost exponentially, aluminum supplier Novelis is preparing to provide customers—be they OEMs or suppliers—with solutions, not only such things as aluminum sheet products for closures, but the company has developed what it says is the first-ever aluminum-sheet battery enclosure.

According to Pierre Labat, vice president, Global Automotive, Novelis, the battery enclosure was designed to accommodate 90-kWh battery backs, which is the size that one might find in an electric pickup or large SUV. What’s more, it is engineered “to be affordable at mass production volumes,” as in 50,000 units per year. He explains that by making it with sheet material rather than using extrusions or castings they are able to achieve better cost efficiencies.

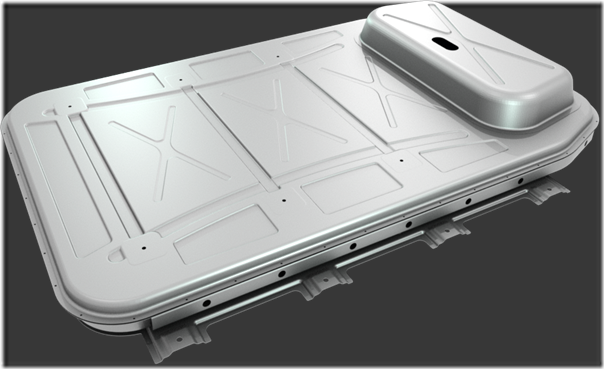

The aluminum sheet-based 90-kWh battery enclosure for EVs.

(Images: Novelis)

Novelis uses its Advanz series aluminum to produce the enclosure. This material provides the formability required for deep draws, yet, Labat points out, it also provides the protection required against things like road debris intrusion. He cites the material’s fracture toughness and energy absorption characteristics, as well.

Aluminum Battery Enclosure

The enclosure is, he says, about 50% lighter than a comparable steel design, which is particularly important for EVs (it is important for vehicles with all types of engines, but there aren’t a whole lot of people who have “range anxiety” with internal combustion engines under the hoods of their vehicles), an Novelis calculates that the mass reduction of the aluminum enclosure could increase the range of an EV on the order of 6 to 10% compared to alternative structures.

What’s more, Labat points out that there are additional benefits to the nonferrous enclosure, such as corrosion-resistance, good thermal management and electromagnetic shielding.

“The product needs to offer value to the customer,” he says. “Not just having lighter weight than steel, but providing these other benefits.”

An exploded view of the enclosure. Aluminum grade use is tailored to meet the specific requirements of each component.

Made For All Sizes

Although the enclosure was designed to accommodate what is a fairly large battery (i.e., a Tesla Model 3 base battery is 50 kWh), Labat says that their design is adaptable to fit different size batteries; it was developed to show that there is an aluminum sheet-based solution that is ready to go.

Of course, given not only Ford’s announced electric F-150, the $500-million Ford investment in Rivian (which has shown two types of vehicles: a pickup and an SUV, both of which are in this enclosure’s proverbial wheelhouse), and Mary Barra’s insistence that when it comes to an EV pickup, GM will not be left behind, perhaps the 90-kWh battery pack is ideal.

RELATED CONTENT

-

UPS to Test Electric Delivery Truck

United Parcel Services of America Inc. is partnering with Los Angeles startup Thor Trucks Inc. to test a fully electric Class 6 delivery truck.

-

Startup Readies Solar-Powered EV

Germany’s Sono Motors GmbH says it has received 5,000 orders for its upcoming Sion electric car, which can be partially recharged by it attached solar panels.

-

Tesla Owners in Germany Ordered to Return Subsidy

Germany has ordered about 800 Tesla Model S electric cars owners to pay back a €4,000 ($4,700) government subsidy they received.

.jpg;width=70;height=70;mode=crop)