on Painting Porsches, Running Trains on Hydrogen & a New ICE from Stellantis

Painting 911s, running trains with hydrogen, charging with a quantum approach, and developing a new engine at Stellantis

Porsche 911: Paint By Numbers

Painting a 911. (Image: Porsche)

The Porsche 911 is built (as are the 718 and Taycan models) at the Porsche plant in Zuffenhausen.

The assembly operation takes two days.

There are 117 steps in the process.

Porsche offers a special paint option called “Paint to Sample.” There are more than 160 pre-approved colors available through the program.

Should a customer want a specific hue, there is the possibility of getting it after a feasibility program that lasts at least five months.

For most Paint to Sample jobs, the additional cost for 911s is $11,430.

For most Paint to Sample Plus jobs (this is the specific color that isn’t in the regular catalog), the price is $22,860.

Step one in the finishing process includes degreasing the body, providing a phosphate coating. Then the body is dipped into a tank filled with electrophoretic paint and deionized water, during which the vehicle is rotated around its own axis for complete coverage.

There are then three coating stages—primer, base coat and clear coat; a standard color uses about four liters of coatings between the three stages.

The base coat is 30 micrometers thick.

The clear coat is sprayed so the layer is between 30 to 50 micrometers thick.

The painted car is dried at a maximum temperature of 392ºF for about 2.5 hours.

The plant had had capacity to do five cars per day with the Paint to Sample process.

They have added capacity so that they are now doing 20 cars per day, or 120 per calendar week.

(If you are interested in all things coating, know that we have a sister publication, Products Finishing, that covers the entire gamut.)

///

Putting Hydrogen on the Rails

Hydrogen-powered train will be piloted in Bavaria next year. (Image: Siemens Mobility)

Anyone who has spent any time traveling around Germany knows that the Autobahn notwithstanding, there is an extensive and well-used rail network in the country.

The Bayerische Regiobahn (BRB), which operates in Bavaria, will pilot a two-car hydrogen-powered train next year.

The train is built by Siemens Mobility. Albrecht Neumann, CEO Rolling Stock, Siemens Mobility said:

“Our Mireo Plus H is the latest-generation hydrogen-powered train. It features high driving power, excellent acceleration capability and a large operating range. This will make rail transport faster, more efficient, eco-friendlier, and more comfortable. The hydrogen-powered drive is an emission-free, advanced form of propulsion for trains that decarbonizes rail transport and makes a substantial contribution toward reaching our climate goals.”

The fuel cells are mounted on the roof of the train. Then beneath the floor are batteries sourced from Saft. (Siemens has also developed a battery-powered version of the Mireo Plus platform.)

The Run

The pilot program, which is planned to include passenger service as of January 2024, will make the run between Augsburg and Füssen (west of Munich), which is about 56 miles.

Bavaria’s Transport Minister Christian Bernreiter:

“I’m really pleased that we’ll soon be able to introduce this innovative technology in Bavaria and test it in regular operation. We’re working closely with our partners to get this lighthouse project under way because we’re convinced hydrogen propulsion can also contribute to attractive and even climate-neutral passenger rail transport.”

They take trains very seriously in Germany.

///

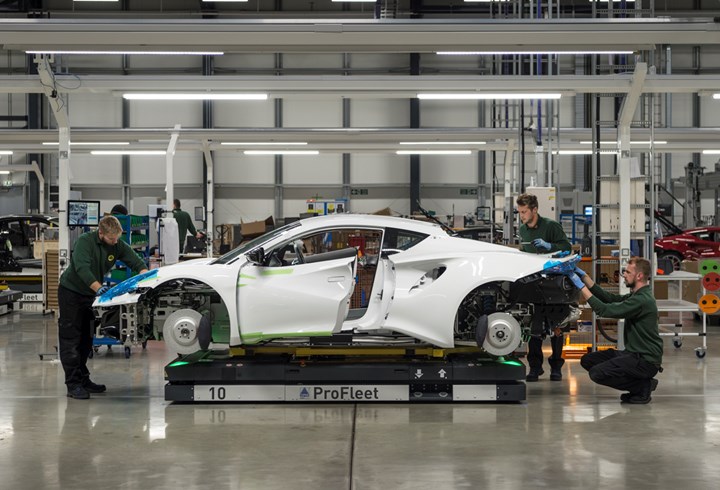

Tour Lotus If You Really Like It

Lotus is offering factory tours. And charging Lotus-money to take one. (Image: Lotus)

Automotive factory tours are always illuminating. If nothing else, it is remarkable to see how vehicles come to be from an orchestration of a multitude of elements that are unidentified to the unpracticed eye, panels that are recognizable yet individual (you might know a quarter panel when you see it, but it looks odd by itself), and things that are known (steering wheels, seats) but aren’t yet in places where they are expected to be.

The Lotus factory tours at its Hethel came to a temporary end five years ago. The company was undertaking a £100 million redevelopment at the site.

But the plant is redeveloped and now the tours are back. There are two groups per day and no more than eight people per group. A tour lasts approximately two hours.

Price for the Lotus Factory Tour? £95. That’s $125 U.S.

We may be fans of factory tours, but given that a one-day ticket to Disney World is $109. . .

///

2022 Corolla Hatchback XSE

Once Corollas were, well, functional in appearance. Now they are functional in terms of operation and stylish to boot. (Image: Toyota)

Over the next few weeks we’ll be looking at some vehicles that are comparatively economical (remember: according to KBB, in February the average transaction price for a new vehicle was $46,085) and fairly fuel efficient.

Although some might think that the Toyota Corolla is “over looked,” that is not borne out by the numbers: in 2021 248,993 Corollas were sold in the U.S., an increase of 6% compared with 2020, and the 2020 number of 237,178 is nothing to sniff at.* The point is that the Corolla, which has been available in the U.S. market since 1968, has been produced so many times that Toyota has gotten really, really good at it. Which redounds to the people who are spending their money on the car.

For the past several years the Corolla at your local dealer has been a sedan.

But the car here is a four-door hatchback.**

Other parts of the world have continued buying hatches, which probably has something to do with why there is stylish sheet metal on the Corolla Hatch, as the Toyota designers have been competing with, say, the vehicles being shaped by the fashionable French.

The Hatch of the Hatch

Hatches do provide a bit of benefit when it comes to loading cargo. (Think of a crossover: in the back it has a. . . hatch.) There are 17.8 cubic feet of cargo space behind the second row of the Corolla Hatch. And should someone opt for foregoing the spare tire and having a tire repair kit instead, the capacity goes to 23 cubic feet.

Given that this is a hatch on a compact car, you wouldn’t imagine that the effort would be too demanding when it comes to opening, but Toyota engineers went a step further, by making the hatch out of two plastic materials (Toyota Super Olefin Polymer, TSOP; acrylonitrile butadiene styrene, ABS).

The vehicle looks sporty, and in the XSE trim there are additions to that, such as 18-inch alloys. Inside there is leather and visible stitching. In fact, the inside is exceedingly fresh, with the IP being clean and quickly sweeping from pillar to pillar.

Another aspect notable about the inside is that you don’t hear annoying noises from the outside.

Not only is this a function of the careful attention to body gaps and a solid architecture (TNGA), but the use of various sealants, foams, pads and even bona-fide Thinsulate. The cabin is remarkably quiet.

But, of course, the sportiness is measured by the performance.

The Corolla Hatchback has a 168-hp, 2.0 liter four cylinder engine that is mated, in the case as driven here, to a six-speed manual transmission.

The manual is named the “iMT,” for “intelligent manual transmission.” The smart part of this is manifest in engine revs being matched during gear changes so there is a minimization of jerkiness. Very smooth.

Fuel consideration

Once manuals were associated with higher fuel efficiency than could be attained with an automatic.

However, the Corolla Hatch is available with a continuously variable transmission (CVT) that bests the manual (and it has nothing to do with people who drive sporty(ish) vehicles with manuals being more aggressive on the throttle).

An XSE with a manual gets an EPA estimated 28/37/31 mpg. With the CVT it is 30/38/33 mpg.

Base MSRP for the vehicle drive? $23,765

*To put that number of Corollas in context: In 2021 Ford sold a total 64,338 cars in the U.S. That is the total number for all of the cars sold. Although its strategy is to focus on crossovers and trucks, with the exception of the exceptional F-Series, there is not a single nameplate in the lineup that has ~249K sales. The closest is the Explorer, at 219,871.

**Sometimes the closure panel that is a hatch is counted as a door, as in a car with four human access ports (a.k.a., doors) and a lid on the back for cargo is called a “five-door hatch.” To which I respond: “Huh?”

///

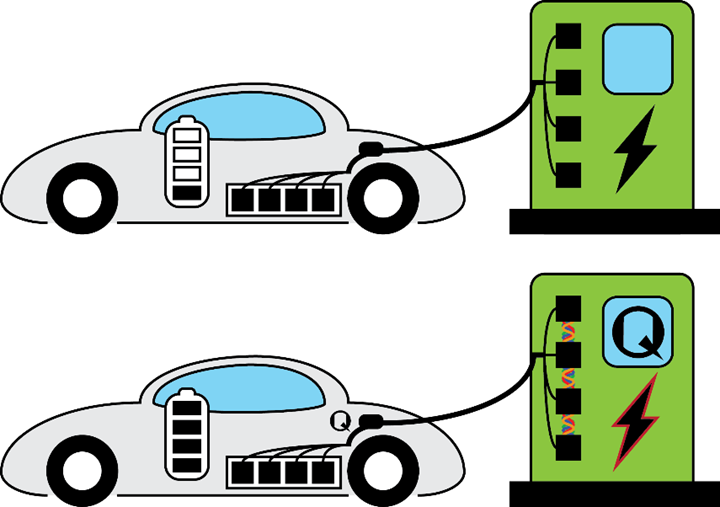

Quantum Charging

Scientists posit that quantum charging methods can provide an electric vehicle with a full charge in a matter of seconds compared with conventional approaches. (Image: IBS)

First, realize that this comes from work performed by scientists from the Center for Theoretical Physics of Complex Systems within the Institute for Basic Science (IBS) in the Republic of Korea.

So we’ll try to simplify.

The issue is electric vehicle battery charging (not warp drive). Research has been going on for about a decade trying to determine if, as IBS has it, “quantum resources, such as entanglement, can be used to vastly speed up the battery charging process by charging all cells within the battery simultaneously in a collective manner.”

The collective approach, known as “global operation,” has each of the cells communicating to one another simultaneously.

The researchers (Ju-Yeon Gyhm, Dominik Šafránek, and Dario Rosa, “Quantum Charging Advantage Cannot Be Extensive Without Global Operations”, Physical Review Letters (2022)) determined that while the conventional approach to charging has a speed that increases linearly with the number of cells, “quantum batteries employing global operation can achieve quadradic scaling in charging speed.”

Which Means. . .?

An EV with a quantum battery consisting of 200 cells could be charged 200 times faster than what they describe as a “classical” battery. (Scientists are well ahead of the rest of us who still think that battery tech going into vehicles right now is fairly advanced.)

Or put into context: a full charge at a quantum charging station could be accomplished in about nine seconds.

Almost sounds like the bending of spacetime. . . .

///

Stellantis Launches a New Engine. Yes, Gasoline Engine*

The >500-hp, 3.0-liter, twin-turbo Hurricane I6. Yes, an all-new engine from Stellantis that runs on. . .gasoline. (Image: Stellantis)

Micky Bly, who has been working in the world of powertrains since 1990 and is now head of Propulsion Systems for Stellantis, says that throughout his career he’s heard people say that there are changes in the industry that represent a “once in 100 year transformation.”

“This time,” he says, “I really think that’s going to stick.”

Bly is talking about the transition to electrification.

In the case of Stellantis, CEO Carlos Tavares announced the corporation’s “Dare Forward 2030” plan, which includes the goal to have a leadership role in decarbonization, becoming carbon net zero by 2038.

Tavares stated: “As part of that leadership, we are setting the course for 100% of sales in Europe and 50% of sales in the United States to be battery-electric vehicles (BEVs) by the end of this decade. We plan to have more than 75 BEVs and reach global annual BEV sales of 5 million vehicles by 2030.”

Bly’s comment comes as he is unveiling. . .an all-new internal combustion engine, the Hurricane, a 3.0-liter, twin-turbo I6, which comes in standard output (SO) and a high output (HO) versions.

While some people have argued that there will be no more new internal combustion engines, that it is all about improving and refining existing ones that will soon sunset, Bly makes a couple points:

- The Hurricane is targeted at use in vehicles based on the STLA Large and STLA Frame platforms: things like big SUVs and trucks (yes, yes, they are working on an electric Ram pickup). “We are working on EVs, every day, every night,” Bly says, “but we have an immediate need for more power density.” More power density in its gasoline-powered engines.

- If 50% of the sales in the U.S. by 2030 are electric, then Chrysler, Dodge, Jeep, and Ram will have 50% using internal combustion engines, so the company might as well have ones that can get the job done in those large vehicles. Bly also notes that the engine lends itself to hybrid applications, so there is the potential of electrification. (Or perhaps better put: “the probability of electrification.”)

They have been working on the Hurricane since 2019, Bly says, and one of the things that they did in the program was spend over a year “in the virtual space”—CAE, CFD, etc.—in order to achieve the power density they are looking for. Bly says that an advantage to this approach is that they were able to forego the multiple physical builds (produce, test, change, test, change. . .) that have been the norm. He refers to these as “cycles of learning.” Now the cycles are being conducted digitally.

About That Power Density:

- SO: >400 hp/450 lb-ft of torque (133 hp/liter)

- HO: >500 hp/475 lb-ft of torque (166 hp/liter)

Rather than a single large turbo, there are two smaller turbochargers, each taking care of three cylinders. This means they spin faster, thereby minimizing turbo lag. The SO turbos provide a peak boost of 22 psi; it is 26 psi for the HO.

Aluminum-Intensive

Both versions are based on a deep-skirt cast-aluminum block with a structural aluminum alloy oil pan. There are a forged steel crankshaft and forged steel connecting rods. The HO has forged aluminum alloy pistons; the SO has die cast aluminum alloy pistons.

Overall, the two versions have 96 common parts for manufacturing efficiency.

(And presumably to help Bly and his team pencil the financials for the Hurricane.)

Spraying the Cylinders

One thing that Bly says is notable is the use of a plasma transfer wire arc (PTWA) coating on the cylinder bores instead of a cast-in cast iron liner.

His team worked with supplier (and part of Stellantis) Comau on developing the process that is being performed at the Saltillo North Engine Plant where the engines are built.**

Briefly: a steel alloy wire is heated at 2,300°C, which results in the formation of microscopic particles that are propelled to the surface of the cylinder. This is followed by a honing process to create a surface for oil retention.

Fun fact

The SO engine weighs 430 pounds.

The HO engine weighs 441 pounds.

If the PTWA wasn’t used, the mass of each of the engines would be 3 pounds greater.

The Long Run

Micky Bly: “This engine, unless regulated out, will last a long, long time.”

There are eight years between now and 2030, and that 50% isn’t going to disappear on December 31 of that year.

*The Hurricane SO is premium recommended. The HO is premium required.

**Pre-pilot production began at the plant in July 2021. Engine number one was produced in November 2021. The engine wasn’t “officially” revealed until March 25, 2022. Seems that they’re pretty good at keeping things under their hats.

///

RELATED CONTENT

-

On Audi's Paint Colors, the Lexus ES 250, and a Lambo Tractor

From pitching a startup idea to BMW to how ZF is developing and using ADAS tech to a review of the Lexus ES 250 AWD to special info about additive at Toyota R&D. And lots in between.

-

On Charging, Sustainable Tires, the Lincoln Nautilus and more

Charging at home, driving on plastic, cameras for exterior, Fisker and Foxconn, and the Lincoln Nautilus reviewed

-

On The Jeep Grand Cherokee, 2022 Nissan Pathfinder, and More

An inside look at the Detroit Assembly Complex-Mack; a innovative approach to waste-free, two-tone painting; why a forging press is like an F1 car; and other automotive developments.

.jpg;width=70;height=70;mode=crop)