on environmental interior design, autonomous mowing & looking at infrastructure like a tree

On designing the Volvo EX 30 interior. . .inside BMW Dingolfing. . .the Fiat Topolino. . .the U.S. EV charging network. . .EV and electrocution. . .Tesla’s gigacastings. . .Volvo V60 review. . .

Inside the Volvo EX30

The Volvo EX30 revealed last week in New York City.

One of the things about electric vehicles that is sometimes overlooked is that while there may be no tailpipe emissions (and no tailpipe), there are materials used to construct the vehicles that have environmental impacts, too.

If a point is to have vehicles that are more environmentally benign than those powered by internal combustion engines, then it just can’t be about zero in-use emissions.

What about the building? What about the end-of-life recycling?

For the new Volvo EX30, a small electric SUV, the smallest of the Volvo SUVs, the company is able to point out there is less steel and aluminum used to build it than the others in the lineup—but that’s because its smaller.

(This is like pointing out a cupcake takes less frosting than a birthday cake.)

But to provide some substance to that observation:

- About 25% of the aluminum used is recycled

- Some 17% of the steel is recycled

And as no vehicle is compete without plastics:

- ~17% of the plastics are recycled

They’ve really taken the attention to a more sustainable approach on the interior of the EX30.

Sense & Sound

One example is the soundbar that runs across the top of the instrument panel, just below the windshield. Rather than locating speakers in the doors or A-pillars, by centralizing and localizing the speakers there is a reduced amount of wiring and materials required. (The audio is by Harman Automotive, so this isn’t some skimpy sound device.)

Yes, even paying attention to what’s put in to a vehicle and how it is deployed matter.

Lisa Reeves, head of Interior Design at Volvo, at the North American reveal of the compact SUV in New York City last week, said she and her team worked toward a “purity of design” for the EX30, a large portion of which is based on using materials like flax—which can be regrown—and wool—which can be re-sheared—for interior surfaces.

They’ve taken plastic window frames, ground them up, and added them to a polymer base.

Visibly Reused (But Looking New)

While it is certainly not common for various materials to be recycled or purposefully used for applications in vehicles, in many of these instances (1) the recycled materials are used in non-appearance applications (e.g., inside the trunk) or (2) the materials are deployed so that they call attention to themselves (i.e., “Hey, look at me: I am a part using recycled materials, which explains why I don’t look as good as one made with virgin materials” (yes, assuming that a panel could talk)).

But in the case of the EX30 these materials are used in such a way that they enhance the interior look, or they are transparent regarding their source (e.g., using pine resin for a polymer rather than a petroleum-based product isn’t something that is discernable). In the photo above, the speckles, which are confetti-like, are from the ground window frames.

And Reeves pointed out that there is a high level of sensibility to the practice.

For example, there is a good likelihood that those of you who are reading this are either wearing jeans right now or will be within the next few days.

Reeves explains that when jeans are recycled, the shredding results in both long and short fibers. The long fibers can be used to create yarn, which can be used to make new jeans.

But the short fibers can’t be used for that application. So Volvo is using them for interior trim applications. Again, a situation where the aesthetic is one that is attractive without calling attention to itself.

The denim is used for the trim panels on the interior execution that is named “Indigo,” one of four curated for the vehicle. The others are Breeze, Mist and Pine.

Not a Horseless Carriage

Another interesting material that is being used for the EX30, which made its debut a couple years back in the Volvo C40 Recharge, is “Nordico.” This is used on the seating surfaces of the EX30. It is made from materials derived from recycled PET bottles, corks from the wine industry, and biomaterials from forests in Sweden and Finland.

I asked Reeves whether this is meant to be a leather replacement, the sort of thing that an increasing number of OEMs are deploying.

No, she told me. This is a material with its own character, a new material for a new age. Let’s face it: leather has been used in vehicle interiors going back to the days of horse-drawn carriages, so at some point its day will be done. (The Volvo approach is going to help with putting that behind us.)

I also asked about the use of metal for trim and she replied that deployment is both minimal and recycled.

The Holistic Whole

Stepping back and looking at the interior as a whole, Reeves said, “We were trying to create a purity of design as the first read—something really clean and welcoming. A well-organized space.”

She continued, “Then we go into the form and the materials and determined how to create balance for a harmony within the space.”

One of the points she made, a point that is more often heard in the field of building architecture rather than—surprisingly—vehicular architecture is “We need to learn to design for disassembly.”

Reeves explained, “We focused on using the components in the smartest way. There are many components and vehicles in the car—and they all take materials and energy to make.”

Get (It) Back

So, she continued, the goal was to provide customer features in a way that would be satisfying—if not delightful—while focusing on how the materials used could be readily reclaimed after the EX30 has served its useful life.

For example, going back to the aforementioned soundbar and the elimination of the related speakers and wiring in the doors that would otherwise be there: this not only simplifies the disassembly, but it also opens up space for storage.

Like the design of many current interiors, the EX30’s is thoughtfully cohesive.

Unlike the design of many current interiors, Reeves and her colleagues looked at it from the standpoints of before it exists (i.e., considering the materials to be used), in use (optimizing functionality for the driver and passengers), and after the vehicle goes out of use Reeves: “We need to get those materials back.”)

///

Some Things to Know About BMW Dingolfing

Given the number of robots in this photo, it seems fairly clear that the BMW Dingolfing plant is highly flexible. (Image: BMW)

While more and more German cars are coming from places other than Germany, BMW still has a big production footprint in Bavaria:

- The BMW Group Plant Dingolfing has been producing cars for 50 years (September 1973)

- It is BMW’s largest manufacturing operation in Europe

- More than 18,000 employees work there

- There were >280,000 vehicles built in the factory in 2022

- There are three electric vehicles produced there: the iX, the i7, and as of last month, the i5

- All three of those vehicles have a flexible architecture: full EV, plug-in hybrid or traditional ICE powertrains are available

- BMW spent >1-billion euros to accommodate the vehicles in Dingolfing

- The 5 Series is an essential product at the plant: of the 8 million vehicles built since 1973, two thirds are 5 Series

- By 2024 they plan to build >40% EVs in the plant

- Dingolfing is in Lower Bavaria, a region BMW is highly supportive of. Milan Nedeljković, member of the BMW Board of Management responsible for Production: “Nine out of ten BMW vehicles produced are sold to customers outside of Germany these days. Despite this, we have more than half our employees here, especially in Bavaria.”

However, it needs to be mentioned that the biggest BMW Group plant in the world is in. . .South Carolina. BMW Manufacturing Co., LLC, based in Spartanburg, has an annual production capacity of 450,000 and is the global source of the BMW X3, X3 M, X5, X5 M, X7, X4, X4 M, X6, X6 M, and XM.

Still, it is nice to know that BMWs in abundance still come from the land of lederhosen.

///

An Eight-Letter Word for “Cute”

No, this isn’t a Pixar car come to life but an actual, full-size (well, for it, anyway) Fiat Topolino. (Image: Fiat)

The Fiat 500 is, to understate it, a small car.

Just 139.6 inches long.

To put that into perspective, the last-generation VW Beetle was about 2.5 feet longer (168.8 inches).

Now imagine something even smaller from Fiat:

The Topolino.

Which is just 99.8 inches long.

More than three feet shorter than the Fiat 500.

The diminutive EV just launching in Europe is 60.2 inches high and 55.1 inches wide.

It seats two.

The Topolino has a 5.4-kWh battery that provides a range of up to 46.6 miles.

According to Fiat:

“It can be purchased with a monthly rate in line with the needs and possibilities of its targeted audience. An affordable monthly amount of money conceived to promote electric city lifestyles and usually spent on a subscription for a pay-per-view TV or what you’ll pay as monthly fee for public transports.”

Targeted audience?

The company says that depending on the market, this urban transportation device can be legally driven by those who are 14 year old (and up).

No, you’ll not see the Topolino, which is so cute so as to make the Fiat 500 look downright dowdy, on U.S. roads.

///

Riding or Mowing with Autonomy (Bet on the Latter)

An autonomous vehicle with immediate results: an electric lawnmower for large turf applications. (Image: FireFly Automatix)

General Motors executives still think—as of last week’s earning announcement—that come 2030, Cruise, its autonomous tech/vehicle/service operation (not the compact Chevy that ended in model year 2019, the Cruze), will have annual revenue of $50-billion by 2030.

Which would be quite a transformation.

In 2022 Cruise lost $1.89 billion.

- During Q2 2023 Cruise lost $600 million.

- During Q2 2022 Cruise lost $500 million.

Not the sort of direction toward profitability one might take.

What seems like a more useful, practical, and cost-effective use of autonomous technology: lawn mowing.

Not residential lawns. But farm-scale.

A 100-Inch Mower

Last week FireFly Automatix, a company developing equipment for the “turfgrass industry,” introduced the M100-AV.

It is an autonomous electric vehicle.

It is equipped with a LiFePO4 battery that provides the ability to mow up to 25 acres per charge at speeds of seven acres per hour. It cuts a 100-inch swath. (The approximate length of the aforementioned Topolino.)

There are four independent electric drive motors synchronized with two independent steering motors. The drive motors are designed for a 100,000+ hour life.

Recharge time is about two hours.

It has a lidar system for obstacle avoidance and intelligent path planning.

Not as comprehensive as Cruise (which deploys lidar, radar, cameras, ultrasonics). But apparently does the job.

View from a Prospect

Said Scott DeBuck, who owns this summer’s Turfgrass Producers International host farm, of the M100-AV: “Its cutting performance produces truly beautiful results, and the capability to program various mowing angles is truly astonishing.”

///

Money for Charging

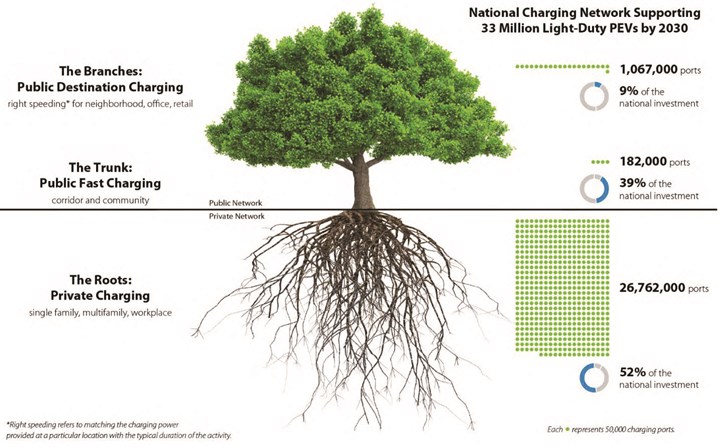

Note how the NREL has home/workplace charging as the basis for a national charging network. (Image: NREL)

An estimated $23.7-billion has been announced, as of March 2023, for public plug-in electric vehicle charging in the U.S. through the end of the decade, according to the National Renewable Energy Laboratory’s (NREL’s) report “The 2030 National Charging Network: Estimating U.S. Light-Duty Demand for Electric Vehicle Charging Infrastructure.”

A lot of money. But enough?

The NREL report notes that the International Council on Clean Transportation published a white paper that estimates if there are 26-million light-duty plug-ins on the road by 2030, there would need to be 2.4-million workplace and public charging ports, which would require a $28-billion investment. Add in residential (one and multi-family) residential charging, that’s another $20.5-billion.

Atlas Public Policy calculates to get the U.S. to 100% EV sales by 2035 (highly unlikely, of course), it would require $39-billion in public charging infrastructure by 2030. Add in the aforementioned residences and public depot charging, and the tab comes to $87-billion by 2030.

Still, the NREL report estimates that the funding for the the build-out will be there by 2030, figuring that given the monies so far announced will be supplemented by additional public and private investments.

What does it see a 2030 EV charging looking like?

A total of 26- to 35-million charging ports that will be based on:

- 26.8-million privately accessible ports (Level 1 and Level 2) at residences and workplaces

- 182,000 publicly accessible fast charging ports

- 1-million publicly accessible Level 2 ports in places like high-density neighborhoods, office buildings and shopping outlets

Although the report seems bullish on private charging, according to Stewart Stropp, executive director of EV intelligence at J.D. Power, 85% of EV charging is done at home. So it is happening.

However, based on data in the J.D. Power 2023 U.S. Electric Vehicle Consideration Study, it is what happens outside the home that is having an impact on purchase consideration.

Stropp: “The biggest friction point for consideration is the availability of public chargers.”

///

Shocking Performance

Don’t try this at home. Or anywhere else, for that matter. (Image: Kia UK)

“In the event of a collision, currently electric vehicles have a circuit breaker that isolates the battery from working on any other component of the car. This will prevent power surges, but it does not reduce the voltage stored in what we call the DC ‘bus’.

“The bus voltage in most electric car models is 400V, which is much higher than the voltage in our home systems at 230V, as well as industry levels at 380V.

“To significantly reduce the risk of a fatal electric shock in the case of a car crash, we need the voltage to be 60V or less and to reduce to that level in under five seconds.”

That’s Dr Yihua Hu, from the University of York’s School of Physics, Engineering, and Technology. He and his colleagues at the U.K. university conducted research on the subject of EV safety last year. The work was published in IEEE Xplore (“An Embedded Fault-Tolerant Control Method for Single Open-Switch Faults in Standard PMSM Drives.”)

A Google search of “Can you be electrocuted by an electric car” returned 1,980,000 results.

Clearly there are (1) an objective issue and (2) a rather large concern.

So it seems somewhat odd that as part of the launch of the Kia EV9 in the U.K. the company employed Jodie Kidd, a woman described as a “model and car enthusiast,” to be “electrocuted with more than a million volts.”

Kia UK:

“Sitting on a raised platform and protected from a ‘lightning machine’ only by a chainmail Faraday suit to conduct electricity around her, Jodie was able to control the electricity with her fingertips and shoot streams of lightning from her hands.”

Kidd is quoted:

“Being electrocuted was one of the most petrifying things I’ve ever done – but also such an amazing experience. Not many people can say they have had a million volts through their body and been able to shoot lightning with their fingers!”

Ah, no.

Of course, people plugging in an EV are unlikely to be contained in a Faraday cage so the current is conducted through the cage, not the person, Ms. Kidd in this example.

///

Gigacastings at Austin

Two gigacasting (front and rear) inside the Tesla Austin plant: possibly the Cybertruck in becoming. (Image: Tesla)

Tesla Gigafactory Austin, which includes 10-million square feet of manufacturing space, is doing the slow ramp to getting the Cybertruck out into the world.

During the Tesla Q2 earnings call a couple weeks back Elon Musk said:

“With regard to our Cybertruck, we continue to build our release candidates of the Cybertruck on our final production line in Austin. I’m actually here in Austin at the Gigafactory. This is the first truck that we’re aware of that will have four doors over a six foot bed and will fit into a 20-foot garage. So, it’s sort of biggest on the outside, but it’s even bigger on the inside. So it’s -- I think that’s a -- one of the elements of good design is it should feel bigger on the inside than it looks on the outside.

“And this is no small car, but we really cared about the exterior dimensions of the Cybertruck down to the last millimeter. So just -- we try to get right in the middle of the Goldilocks zone, not too big, not too small and then really maximize the utility of the volume. And we can’t wait to start delivering it later this year.”

The truck exterior design is, well, controversial.

- But think of this:

The truck market is dominated by the Detroit Three (F-150, Silverado, Ram 1500) and Toyota (Tacoma), all of which have similar exterior styling.

When companies like Nissan have tried to enter the space (Titan) with similar styling, its market performance is weak—though the first half of 2023 Nissan delivered 10,550 Titans and Ford delivered 8,757 F-150 Lightings.

So why shouldn’t Tesla try something completely different?

The Cybertruck will be based on gigacastings.

As part of the earnings call investor deck, Tesla provided a picture of what is likely the front and rear castings for the truck, so if you’re wondering what they might look like, there you go.

Crash

One of the criticisms that has been leveled against the gigacasting approach is that after an accident there could be a significant replacement cost for the castings.

Lars Moravy, vp of Engineering at Tesla, addressed that concern during the call by pointing out:

“[The] Design team works with our collision repair team since we’re a closed loop on this with insurance, and we design specific parts that make it easier and faster to repair. And we have an incentive to do that because we have our own insurance and our own body shops. We expect that we’ll continue to do this, and collision repair will continue to become cheaper and faster over time. And we already make this available to all body shops or our Tesla-approved body shop training.”

Yes, Tesla offers insurance to its owners in Arizona, California, Colorado, Illinois, Maryland, Minnesota, Nevada, Ohio, Oregon, Texas, Utah, and Virginia, so it has an incentive to keep repair costs under control.

///

Volvo V60 Cross Country B5 AWD

Yes, a station wagon. (Image: Volvo)

As we opened with Volvo. . .

There is a common comment heard by automotive journalists that has it that their ideal vehicle is a “wagon with a diesel and a manual transmission.”

We all know what has happened to diesels in almost anything that doesn’t have a bulldog hood ornament.

As for the manual, earlier this year Car and Driver ran a piece about the cars available in the U.S. with manuals (28 of them) that acknowledges in its opening: “Chances are the manual transmission won't be with us much longer. It's a dying breed.” And those guys are manual enthusiasts. Their list of the SUVs could be ticked off by the fingers on one hand with digits remaining.

Station wagons? Once upon a time they were the family vehicle par excellence. You may recall that the Griswold family rolled in the Wagon Queen Family Truckster, a station wagon modeled on a Ford Country Squire, for the “Family Vacation” (1983) movie, and a Taurus wagon for “Christmas”(1989). Seriously silly, but both underscore the fact that station wagons were synonymous with family transportation.

(Automotive journalists don’t think of wagons in the context of families, so that’s not where that comment above comes from. It is more about the comparatively low, long roofline and the consequent cargo capacity. Of course, as most automotive journalists don’t actually buy anything, it is pretty much a fanciful observation.)

As the Volvo brand has its roots in Europe, the V60 isn’t referred to by the company as a wagon but as an “estate.”

No matter. For those of us here it is a wagon. A sedan with a roofline that continues where the trunk is supposed to go. A five-seater (passenger volume: 94-cubic feet).

A car—as it is car-like, even though it carries the Volvo “Cross Country” moniker, which means, fundamentally, that it has more in the way of ground clearance than would otherwise be the norm: 8.1 inches in its case—that replaces aforementioned trunk with a cargo capacity of 22.5 cubic feet.

The practical part of that is that it is much easier to maneuver compared with, say, the Volvo XC60 crossover.

As Volvo is in the process of electrifying everything, know that the V60 is a mild hybrid, with a 48-volt system supplementing the 247-hp 2.0-liter engine that is under the hood. This essentially means that it harvests energy during braking that is then used for propulsive power.

The vehicle is rated at 23 mpg city, 30 highway and 26 mpg combined, so it is not like this is some sort of hybrid hypermiler.

That said, it is 188.5 inches long, 75.4 inches wide and 59.2 inches high, so it is a reasonably sizeable vehicle.

Which brings us to the inside. If you’re at all familiar with Scandinavian furniture, know that the V60 is like a small room that is so decorated. If you’re not, know that it is comfortable and ergonomic, fresh and accessible.

It is powered by gas, not diesel. It has an eight-speed automatic, not a manual. But it is a wagon.

Yes, a car that even an automotive journalist could love.

RELATED CONTENT

-

Jeeps Modified for Moab

On Easter morning in Moab, Utah, when the population of that exceedingly-hard-to-get-to town in one of the most beautiful settings on Earth has more than doubled, some people won’t be hunting for Easter eggs, but will be trying to get a good look at one of the vehicles six that Jeep has prepared for real-life, fast-feedback from the assembled at the annual Easter Jeep Safari.

-

GM Develops a New Electrical Platform

GM engineers create a better electrical architecture that can handle the ever-increasing needs of vehicle systems

-

Multiple Choices for Light, High-Performance Chassis

How carbon fiber is utilized is as different as the vehicles on which it is used. From full carbon tubs to partial panels to welded steel tube sandwich structures, the only limitation is imagination.

.jpg;width=70;height=70;mode=crop)