JLR Uses Aerospace Sensors to Test Lightweight Materials

New metals and advanced composites will be subject to extreme conditions

#aluminum

Land Rover Defender during testing (Image: JLR)

As part of its quest to reduce the weight of future vehicles, Jaguar Land Rover is using advanced sensor technologies to measure how new metals and composite materials perform under extreme conditions.

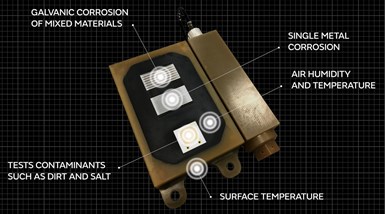

Samples of the materials will be built into aerospace-grade sensors positioned around the vehicles. The tests will evaluate:

- Galvanic corrosion of mixed materials

- Single metal corrosion

- Air humidity and temperature

- Contaminates such as dirt and salt

- Surface temperature

Tough Conditions

The tests will be conducted over the next two years in North America. JLR describes the 250,000-mile regiment as “some of the world’s most extreme physical conditions.”

The all-weather, all-terrain program will include harsh and corrosive conditions through snow, sand and water.

Data gathered from the testing will be shared with the carmaker’s U.K. product development team to allow them to accurately forecast the future behavior of the materials. In particular, the program will evaluate how lightweight body materials fare in terms of durability and maintaining a high-quality finish.

Lightweighting Reality Partners

The new research program is part of JLR’s ambitious Destination Zero vision to completely eliminate emissions, accidents and congestion.

The carmaker also is teaming up with various partners as part of an aluminum consortium and the recent Reality project that aims to reduce the weight of in-vehicle electronics by 60% through the use of recycled aluminum.

RELATED CONTENT

-

Increasing Use of Structural Adhesives in Automotive

Can you glue a car together? Frank Billotto of DuPont Transportation & Industrial discusses the major role structural adhesives can play in vehicle assembly.

-

Light Rider

When you think of the forthcoming LA Auto Show and Los Angeles in general, you may think of (1) very expensive, very large vehicles being piloted by very egotistical stars and (2) very jammed freeways full of the aforementioned, as well as numerous other vehicles of a less ostentatious variety.

-

Creating a Low-Cost Chassis Architecture

The engineers at Zenos Cars have combined recycled carbon fiber, drinking straws and aluminum to create a chassis for a low-volume sports car.