Machining Gummy Materials: A New Use for Sharpies

Organic films help metal removal Purdue researchers discover

#aluminum

Researchers at Purdue University have determined that organic monolayer films on the surface of a gummy metal or alloy can result in a cleaner cut.

And those organic monolayers can be provided by glue, adhesive film or even a Sharpie.

According to Srinivasan Chandrasekar, Purdue professor of industrial engineering, “This ultra-thin film helps achieve smoother, cleaner and faster cuts than current machining processes. It also reduces the cutting forces and energy, and improves the outcomes.”

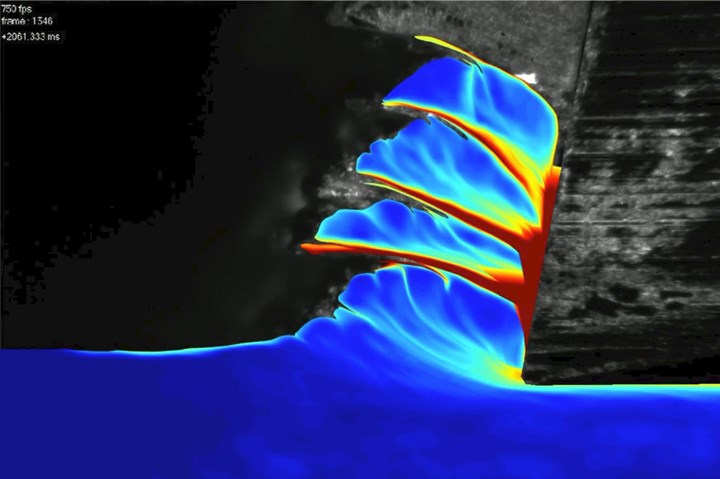

A single organic layer on the surface of a gummy material can result in better machining operations according to Purdue researchers. (Image: Purdue University)

The materials that can benefit from the organic molecules include aluminum, stainless steels, nickel, copper and tantalum.

The researcher discovered that the film on the metal surface by molecular self-assembly can locally embrittle the metal, which allows improved machining operations including cutting, drilling and grinding.

Adds Anirudh Udupa, the study’s lead author and Purdue School of Industrial Engineering researcher, “We are also learning through our discovery more about how environmental factors influence failure of metals.

“As we decipher how the organic molecular films improve the machinability of these metals, the better also is our understanding of common environment-assisted failures in metals, such as stress-corrosion cracking, hydrogen embrittlement and liquid metal embrittlement.”

Small Print

The Purdue researchers worked in collaboration with those at Osaka University (Japan) and the Indian Institute of Science (India). The research is supported by the National Science Foundation and the U.S. Department of Energy.

The study, “Organic monolayers disrupt plastic flow in metals,” by Tatsuya Sugihara, Anirudh Udupa, Koushik Viswanathan, Jason M. Davis, Srinivasan Chandrasekar, was published in Science Advances.

RELATED CONTENT

-

GM Develops a New Electrical Platform

GM engineers create a better electrical architecture that can handle the ever-increasing needs of vehicle systems

-

The Koenigsegg Jesko Has An Amazing Engine

It is hard to believe that this is a vehicle in “serial” production with such extraordinary powertrain performance

-

Robotic Exoskeleton Amplifies Human Strength

The Sarcos Guardian XO Max full-body, all-electric exoskeleton features strength amplification of up to 20 to 1, making 200 pounds—the suit’s upper limit—feel like 10 pounds for the user.

.jpg;width=70;height=70;mode=crop)