Nikola and Additive Manufacturing

Nikola uses additive for fixtures and checking components

This is not something about Nikola Corporation that has the slightest whiff of controversy about it.

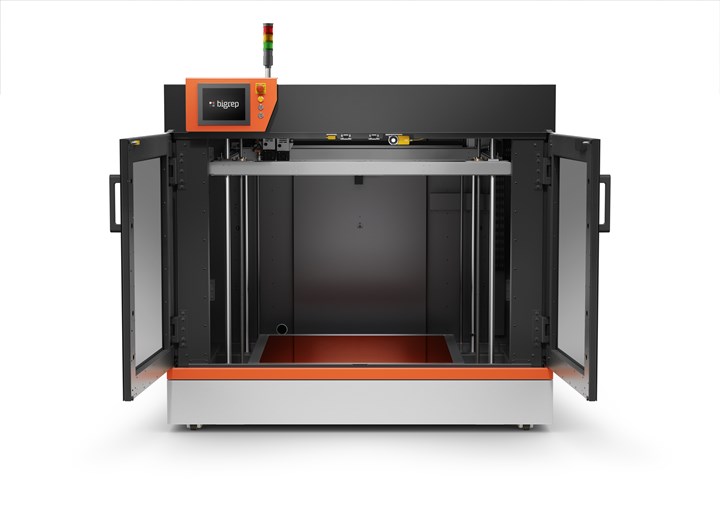

Nikola has acquired a large format 3D printer for use in the development of its trucks, the BigRep PRO from Berlin, Germany-based BigRep.

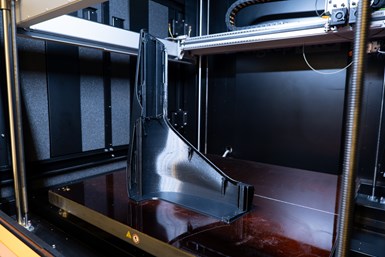

Nikola truck part in BigRep additive machine. (Images: Big Rep)

The machine uses the fused filament fabrication (FFF) process, which uses a continuous 2.85-mm diameter filament of material. Among the materials used by this machine are PA6/66, ABS, ASA and more.

It features what it calls “Metering Extruder Technology” (MXT). The maximum material throughput with a 1-mm nozzle is 230 g/h.

The PRO has a build volume of 1,020 mm X, 970 mm Y and 980 mm Z.

It features a Bosch Rexroth CNC motion-control system that uses 32 integrated sensors and IoT connectivity, so there is speed, precision and repeatability in additive processing, which is key when making large components.

The BigRep PRO. Large-format machine for 3D printing of parts, fixtures, tooling, etc.

Nikola is using the machine for fixtures (assembly, welding and inspection fixtures), printing test components to perform fit checks, and is producing some end-use parts.

Nikola’s technical operations manager Riley Gillman explained, “We selected the BigRep PRO for its large-format build volume, third-party filament compatibility, and state-of-the-art Bosch Rexroth CNC control systems.”

Evidently some of the components Nikola is printing are large: “The first prints that we ran lasted 17 days,” Gillman said. He added, “Since then, we have been pretty much running the PRO non-stop to help us print parts and components using its large capacity of printing, high resolution and accuracy throughout the entire process.”

About BigRep

While BigRep may not be as widely known as some other additive manufacturing vendors (at least not in the U.S.), the company was founded in 2014. Among its strategic partners are Bosch Rexroth, Deutsche Bahn, AIRBUS, and Etihad Airways. Investors include BASF and Koehler. It has shipped more than 500 machines.

The company has focused on large-format printers, with its initial product, the ONE, offering a one-cubic meter build envelope.

RELATED CONTENT

-

The Koenigsegg Jesko Has An Amazing Engine

It is hard to believe that this is a vehicle in “serial” production with such extraordinary powertrain performance

-

On Automotive: An All Electric Edition

A look at electric vehicle-related developments, from new products to recycling old batteries.

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .

.jpg;width=70;height=70;mode=crop)