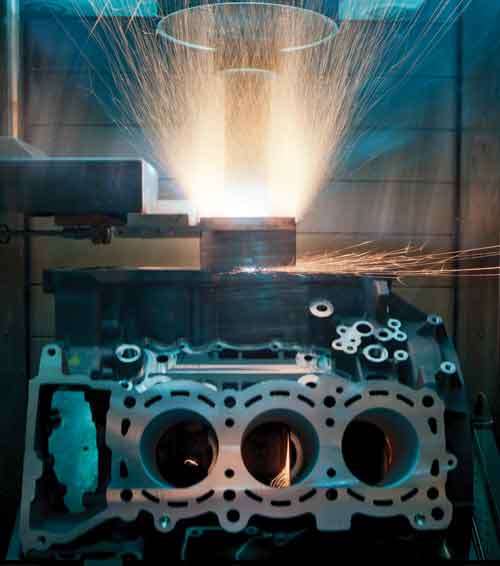

Coating & Machining for Better Bores

Heller is working on productionizing what it calls “CBC”—Cylinder Bore Coating.

#aluminum

Aluminum blocks without cast iron cylinder sleeves? Yes. And not just for high-performance engines. In fact, a cylinder bore coating process that Daimler AG has been working on since 1998, is being developed by Daimler, other partners, and Gebr. Heller Maschinefabrik GmbH—parent company of Heller Machine Tools (heller-us.com)—for mass-production applications by companies that don’t put the three-pointed star on the hoods of their vehicles.

Yes, the Daimler process is going commercial.

The process uses a twin-wire arc spray that melts iron/carbon wires, then uses nitrogen gas to propel the particles onto the surface of the cylinder bores at a velocity of from 60 to 80 m/sec. The particles are at a temperature of up to 2,000°C. The resulting surface provides both wear-resistance and lubricity.

Daimler has been using its NANOSLIDE process in low-volume production, for, primarily, AMG engines.

But now Heller is working on productionizing what it calls “CBC”—Cylinder Bore Coating. In other words, it is developing the processes and equipment such that this can be applied in high-production engine operations.

There are two pieces of equipment involved. The twin arc spray device, and a Heller MC20 horizontal machining center. The cylinders are prepared via the machining center, then sprayed. Subsequently, there are rough honing, finish honing, and finish machining performed. Whereas in the previous process honing was used in place of the fine boring process, but the boring is faster and imparts a more consistent finish and form to the cylinder. The cycle time to process an eight-cylinder block is six minutes or less.

Vincent Trampus, Heller vp of Sales, said, “Although the technology has only been used for exclusive low-volume series until know, its application in medium-volume production already provides significant competitive advantages compared to existing cylinder lining technologies. The technology complies with the production rules and criteria of the automotive industry. Now, it is only a small step to mass production.”

RELATED CONTENT

-

GM Is Down with Diesels

General Motors is one company that is clearly embracing the diesel engine.

-

Mustang Changes for 2018

On Tuesday Ford unveiled—using the social media channels of actor Dwayne Johnson (this has got to unnerve some of the auto buff book editors)—the 2018 Mustang, which has undergone some modifications: under the hood (the 3.7-liter V6 is giving way to a 2.3-liter EcoBoost four, and a 10-speed automatic is available), on the dash (a 12-inch, all-digital LCD screen is available for the dashboard), at the tires (12 wheel choices), on the chassis (MagneRide damper technology is being offered with the Mustang Performance Package), and on the exterior (three new paint colors). And while on the subject of the exterior, there are some notable changes—a lower, remodeled hood, repositioned hood vents, new upper and lower front grilles, LED front lights, revised LED taillamps, new rear bumper and fascia.

-

on lots of electric trucks. . .Grand Highlander. . .atomically analyzing additive. . .geometric designs. . .Dodge Hornet. . .

EVs slowdown. . .Ram’s latest in electricity. . .the Grand Highlander is. . .additive at the atomic level. . .advanced—and retro—designs. . .the Dodge Hornet. . .Rimac in reverse. . .