Boston Dynamics Stretches Into Autonomous Warehouse Robotics

Julia Hider | Plastics Technology

The robotics company’s second commercial product is designed to take on physically challenging warehouse tasks.

DMG MORI Event Showcases “Machining Transformation”

Julia Hider | Modern Machine Shop

DMG MORI’s Chicago Innovation Days event featured technologies designed to address the difficulties manufacturers face today.

Seeing Is Believing: 3D Vision System Enables Bin-Picking Robot

Julia Hider | Modern Machine Shop

With the help of a 3D vision system and robotic arms from FANUC, MetalQuest was able to automate a physically challenging bin-picking task.

The Softer Side of Robots: Increasing Automation’s Adaptability

Julia Hider | Modern Machine Shop

Robotic applications are expanding thanks to rubber and silicone-based systems that can handle fragile materials or parts in varying sizes and shapes.

Protecting Your Automation Investments

Julia Hider | Modern Machine Shop

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Hermle Event Encourages, Educates on Five-Axis Machining

Julia Hider | Modern Machine Shop

Hermle’s first Five-Axis Summit was designed to show beginners the benefits of five-axis machining and demonstrated how more advanced users can take their capabilities to the next level with automation.

JTEKT Technology Days Showcases Synergies

Julia Hider | Modern Machine Shop

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

#electronics

Using the Toolchanger to Automate Production

Julia Hider | Production Machining

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

4 Lessons Your Shop Will Take Away From TASC

Julia Hider | Modern Machine Shop

The Automated Shop Conference (TASC) will give shops of all sizes and production volumes key insights and practical guidance on how to implement automation.

Kicking RaaS with Robotics as a Service

Julia Hider | Modern Machine Shop

Robotics as a service (RaaS) enabled Behrens Manufacturing to quickly address a severe worker shortage while maintaining its ability to invest in new metal forming equipment.

Okuma Demonstrates Different Perspectives on Automation

Julia Hider | Modern Machine Shop

Several machine tools featured at Okuma’s 2023 Technology Showcase included different forms automation, from robots to gantry loaders to pallet changers.

Grinding Technology Prepares Manufacturers for Business Challenges

Julia Hider | Modern Machine Shop

Studer’s automation solutions, S100 flexible grinding machine and intelligent coolant system can help users with unattended machining, machining a range of workpieces and saving energy.

Better Together: Combining Cobots and Palletization

Julia Hider | Modern Machine Shop

Using a collaborative robot to tend a machine with a pallet changer can help shops maximize unattended machining time.

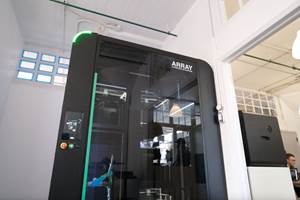

Mosaic Array — Automated Print Farm with Machine Tending and More

Julia Hider | Additive Manufacturing

Mosaic’s Array additive manufacturing system combines multiple forms of automation, including machine tending, material management and scheduling, to enable unattended production.

3D Printed End of Arm Tooling Aids Automation

Julia Hider | Additive Manufacturing

Frustrations with traditional end of arm tooling led Richard Savage to start 3D printing custom versions for injection molding applications, eventually founding a company to fill this niche.

Propelling the Digitization of Manufacturing

Julia Hider | Additive Manufacturing

The past three years have presented a range of challenges for manufacturers, accelerating the adoption of advanced, digital manufacturing technologies. The 2022 Formlabs Digital Factory Event reflected on the industry’s progress and its future.

Preparing a Shop for Automation

Julia Hider | Modern Machine Shop

Ensuring a stable, predictable production process can prevent automation from multiplying existing problems.

Automation Adds Capacity to Capability for Low-Volume Work

Julia Hider | Modern Machine Shop

Investment in machining technology has facilitated growth and diversification at Reich Tool & Design. Now, flexible automation allows the shop to get more out of its machines despite a shortage of skilled workers.

AI to Aid Consistency in Electron Beam Additive Manufacturing

Julia Hider | Additive Manufacturing

Machine vision and algorithms have helped EBAM users address problems as they occur in deposition, but AI could be able to predict problems before they happen.

Prototyping is the Path from Tooling to Production Work

Julia Hider | Modern Machine Shop

As a new owner takes over a tooling shop, he must balance the company’s foundation with his goal of expanding the shop’s capacity to also take on production work.

Avoiding a Failed Automation Integration

Julia Hider | Modern Machine Shop

New features that simplify robot use have blurred the lines between tasks that shops can automate independently from those that will require the support of an integrator. Here’s what shops should keep in mind to avoid a costly failed integration.