Toshiba Touts Electric Motor Breakthrough

Magnetic wedge promises improved efficiencies

Ten 1-gigawatt power plants could be closed if all the electric motors in the world switched to a magnetic wedge design being developed by Toshiba, the supplier claims.

(Images: Toshiba)

As a reference, there are only a few dozen 1-GW or larger facilities in the world. (China’s Three Gorges Dam facility is the largest with an annual capacity of 22.5 GW.)

Why it Matters

Most power plants still run on non-reusable energy (i.e., coal, natural gas or peat) that generates harmful greenhouse gas emissions.

Electric motors account for half of the world's electric power consumption. Thus any improvements can have a positive global impact.

How It Works

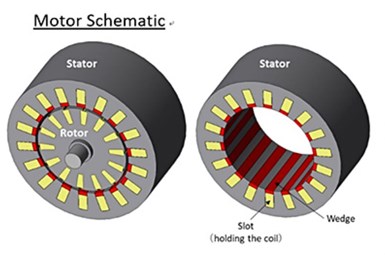

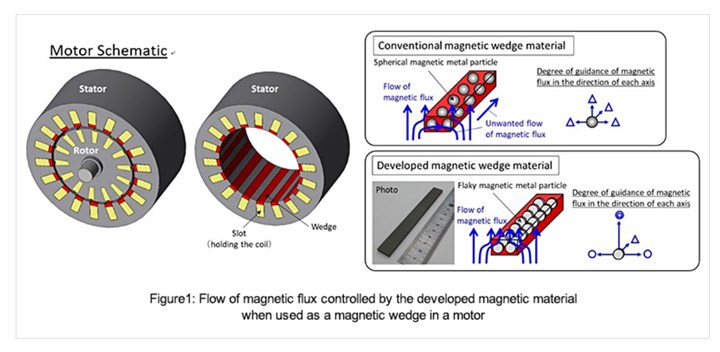

Toshiba says its magnetic material can significantly boost energy conversion efficiency when it is used in a motor’s wedges—the groves that hold coils in place.

Magnetic materials are more energy efficient and better at guiding magnetic flux than non-magnetic ones, but they typically have poor directional control, leaks, low heat resistance and high magnetic losses.

Composed of flaky metal particles, Toshiba’s design is said to alleviate the problems of conventional spherical metal particles. The flaky particles have directional-specific magnetic properties, providing ultra-low magnetic loss and high heat resistance.

In addition, the supplier says, the new material can be installed at minimal cost with no need for design changes.

What’s Next?

In addition to cars, the magnetic motors can be used in industrial and medical equipment, robots and trains. Initial testing in the latter has shown promising results, Toshiba says.

But the real test will be in winning production applications. That’s when you can start adding up gigawatt savings.