Chevy’s Small Block: Story of a Remarkable Engine

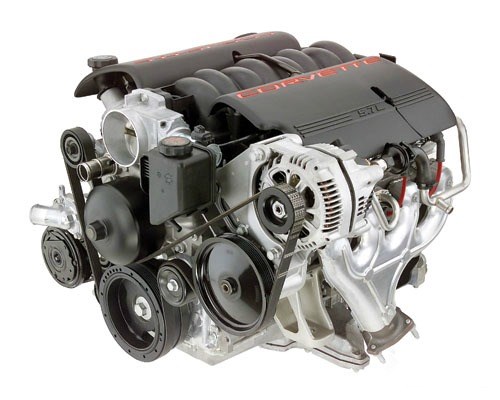

This engine has gone through five generations since the mid-‘50s. Here’s a look at how the next small block—the 450-hp V8 Gen 5 for the 2014—has come to be.

While engine downsizing continues at a brisk rate, it is interesting to note that between 1929 and 1955 Chevrolet offered only six-cylinder engines—who knew that they were ahead of themselves?

The V8 was the result of work done by then-Chevy chief engineer Ed Cole (who was to go on to become president of General Motors), who had transferred to the division from Cadillac, where he’d worked on the premium division’s V8. In the case of Chevy, the goal was to come up with something that would help the Corvette become a bit more performance-oriented than it had been; the Corvette was introduced in 1953.

At the time, Chevys were offered with what was called the “Stovebolt” in-line six that was introduced in 1929. Its nickname came from the visible slotted-head bolts used to assemble it. This was an overhead valve engine. A simple, straightforward engine. Cole wanted to retain not only the overhead valve approach, but the simplicity of the engine, as well.

The engine Cole and his team developed for a 1955 launch is a 265-in.3 compact, 90° V8 with overhead valves, pushrod valvetrain, and 4.4-in. on-center bore spacing. It is 50 lb. lighter than the Stovebolt (a.k.a., the “Cast Iron Wonder”). It produces 195 hp with an optional four-barrel carburetor.

And from then on, this design was improved and enhanced. As Jim Campbell put it, “The Small Block was an instant success because it offered customers high performance and an affordable price in a compact design that was very easy to modify. The Small Block also started a wave of innova-tion—and escalating performance—that transformed the cars Americans drove on the street and track.”

An example of the development: in 1957, Rochester mechanical fuel injection—nicknamed “Ramjet” (remember, this was the 1950s, when jet aircraft were all the thing)—was added so that the now-283-in.3 engine was producing 283 hp. According to Chevy, the only other OEM at the time that offered a mechanical fuel injection system was Mercedes-Benz. And that one horsepower for every cubic inch remains an important metric even today.

Like many things mechanical, the mechanical fuel injection gave way to electronic in 1981 on the ’82 Corvette. But before then, it is worth noting that in 1969 the Small Block grew to 350-in.3, which became something of a benchmark size, as it was the Corvette standard engine dimension through 1996.

In 1985, the Corvette was offered with the L98-code engine, which offered the Tuned Port Injection system. The port-injection design continued until Gen 5, which we’ll get to.

In 1997, with the introduction of the LS1 on the C5 Corvette, the Small Block reached its third generation. This redesigned engine features an aluminum deep-skirt cylinder block and high-flow aluminum cylinder heads. Yet the 4.4-in. bore spacing of the original was kept for Gen 3.

Gen 4 for the Small Block occurred in 2005 with the 6.0-liter 400-hp LS2. 2006 brought the 7.0-liter LS7 engine to the Corvette, which, with its 505-hp rating (redline: 7,000 rpm), is the highest-performance, naturally aspirated small block in Corvette’s history. It features such things as titanium connecting rods, titanium intake valves, dry-sump oiling and more.

In 2009 the LS9—a supercharged small block—was put in the Corvette ZR1: it offers 638 hp.

Next up is Gen 5. And for the 2014 Corvette, things get really interesting. The engine has 4.4-in. bore centers like the Small Block that started it all. But that’s about the end of the similarities. According to Tadge Juechter, executive chief engineer, Corvette, compared with the Gen 4 engine, Gen 5 is “99.9% new.” What did they retain? Starter bolts, piston pins, valve spring retainers, and valve spring keepers.

This engine will have 4.4-in. bore centers like the one that started it all. But this engine produces 450 hp and 450 lb-ft of torque, which is a long way from the original 195 hp of the first Small Block.

There was a comprehensive computer-aided and physical testing regimen for the Gen 5 engine development. This included steady-state airflow assessments, 3D computation fluid dynamics, airflow bench testing, one dimensional, engine cycle simulation, geometric flame propagation analysis, 3D mixing and combustion analysis, single and multi-cylinder combustion testing, and vehicle-level performance and fuel economy analysis. Thirty analysts worked digitally on the engine development program, literally years before the first physical model was produced. They used both commercially available CAE/CAD software as well as specially developed code. It is estimated that there were more than 10-million hours of computational analysis for the engine development.

The Gen 5 uses direct injection, active fuel management (i.e., going to four cylinders from eight when there is light-load driving; this is the first application of the technology for a Corvette), and continuously variable valve timing.

But the big change for the Gen 5 from the Gen 4 is a wholly new combustion system design. Because the engine has overhead valves and because there is direct injection, the flow field, or air-fuel mixture, is more complex. In all, some 75 iterations of combustion systems were digitally developed and analyzed. Factors that were taken into account were the placement of the injector in relationship to the spark plug; the size and angular placement of the intake and exhaust valves; the size and volume of the combustion chamber; and the configuration of the piston head.

The spark plug was moved closer to the center of the combustion chamber. There are 2.13-in. hollow intake valves and 1.59-in. sodium-filled exhaust valves, with the intake held at 12.5° and the exhaust at 12°, compared with the 15° angle for both in the Gen 4. The position of the intake and exhaust valve positions are reversed compared with the location in the Gen 4. The size of the combustion chambers are reduced, and the pistons have sculpted heads, featuring both a dish and riser to manage the fuel motion. The compression ratio is 11.5:1.

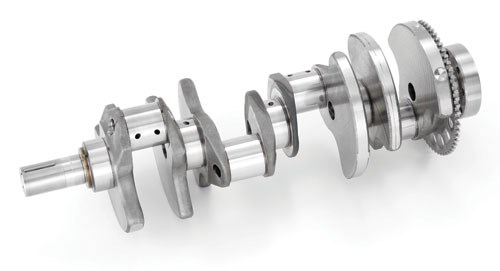

There is a cast 319 aluminum cylinder block with nodular iron main bearing caps in place of the previously used powered metal bearing caps. There is a structural aluminum oil pan. There is a 1538MV forged steel crankshaft with induction hardened journals. The camshaft has a tri-lobe designed lobe that is used to direct the engine mounted direct injection fuel pump; the fuel pump delivers up to 15 MPa. The main and rod bearings are polymer coated. The Gen 5 engine has domed rocker covers. There is a four piece molded and welded composite intake manifold that features a “runners in a box design,” which means individual runners inside the manifold feed a plenum box to facilitate air flow.

The engine design took the vehicle design into account: it is a compara-tively compact engine, just 25.3 in. high. This facilitates a low hood line for the 2014 Corvette. And another notable metric: the mass of the Gen 5 is 465 lb., which makes it lighter than many engines that provide less performance.

The Gen 5 engine is being produced at the GM Tonawanda Engine Plant in New York (north of Buffalo). In April 2010, the plant was awarded a $400-million investment for a then unnamed “new V8 small block engine.” The Gen 5.

The machining is being produced by an array of advanced equipment. Block machining includes four- and five-axis machining centers from Comau and special machines from Gröb. Material handling for the block line includes rail-mounted Fanuc robots and Valiant Automation.

The cylinder head machining is performed, for the most part, by Gröb dual- and single-spindle CNC machines. The material-handling automation is similarly sourced as the head line. Washers for the machining operations are supplied by Dürr.

Whether it is the machining or the performance, the analysis or the execution, the small block Gen 5 is a vastly different engine than its progenitor of Ed Cole and his team back in the early ‘50s. By far.

.jpg;width=70;height=70;mode=crop)